Galvanized Steel vs Aluminum: A Comparative Guide

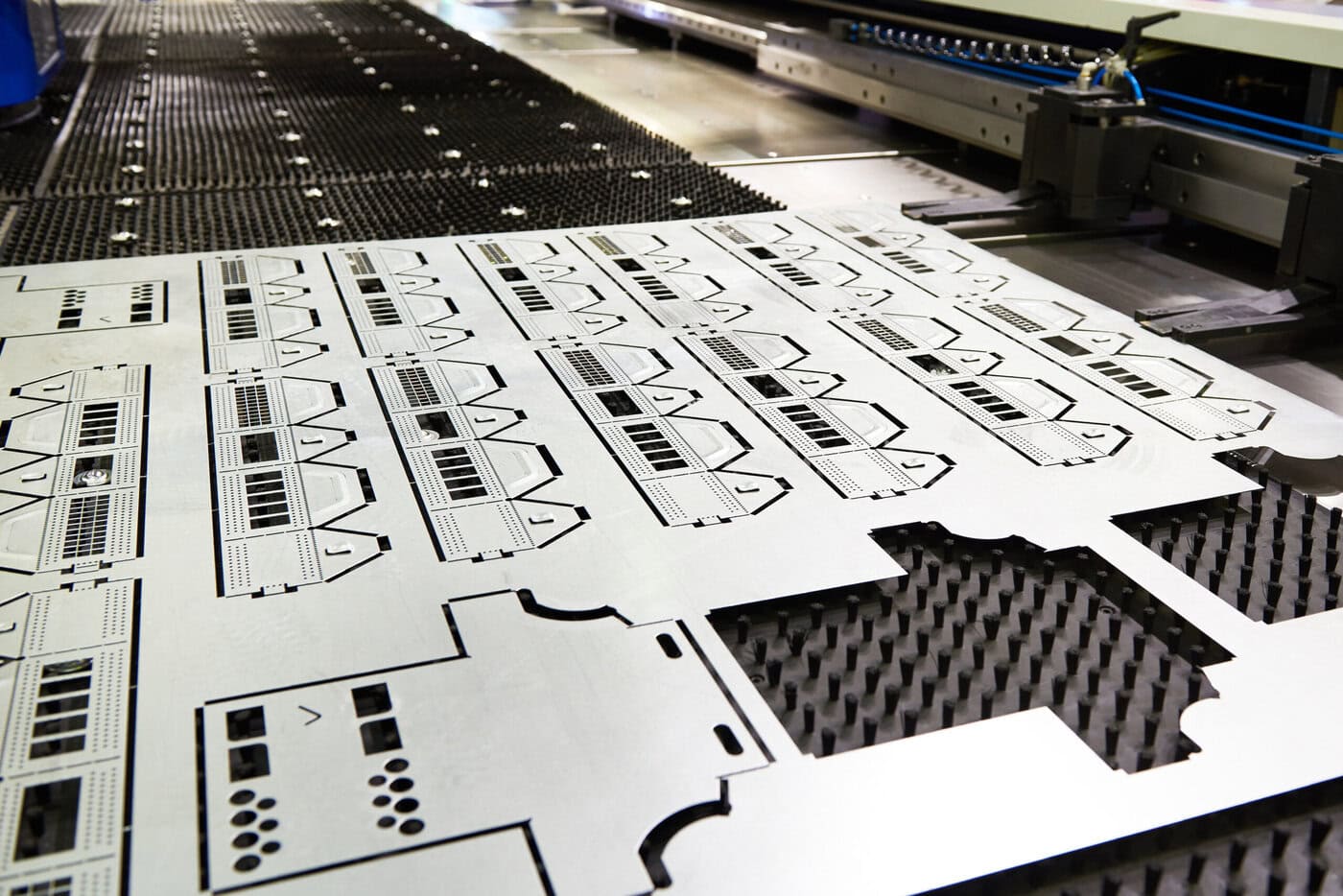

Picking the correct material for your project is a necessity. The wrong option can cost too much, be too difficult to manufacture, and might break when installed. The good news is that our experts at Rapid Axis have experience working with a wide range of…