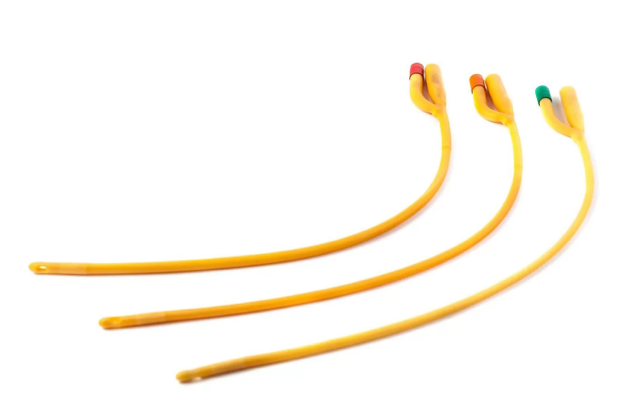

Medical Device

Our History with Medical Device Companies

We have worked with a number of medical device companies over the years including Thermo Fisher, Intuitive Surgical and Becton Dickson. These companies come to us for everything from prototyping in 3D printing, to machining of fixtures to full volume production in injection molding.

Our team at Rapid Axis is the right choice for your medical device projects with familiarity in materials for medical applications and a wide range of capabilities. We offer CNC machining, 3D printing, and injection molding services. In addition, we handle multiple finishing steps.

Other shops will struggle to meet the demands that the medical industry has for devices. We know that quality, precision, and documentation are very important. Since we already have experience in this field, we know what to expect when working with medical device companies. You won’t have to deal with a learning curve or a shop that doesn’t know what they’re doing.

Why Medical Device Companies Choose Rapid Axis

Why do medical device companies choose Rapid Axis so often? There are a few major reasons. Over our decades of experience, we have found out what’s so appealing about our business model.

High-Precision Parts

Above everything else, we prioritize precision in our shop. We know that a lot of different companies can offer manufacturing, but few of them have the expertise and equipment to offer high-precision parts that are worthy of a medical device company’s use.

Whether we’re using CNC machinery, 3D printers, or injection molds, we dial-in all the parameters to ensure the quality is maximized. As part of our proprietary quoting process we do full machine programming and DFM up front so we can be sure to meet your expectations in delivery.

High-precision parts are imperative for your business. If there is a dimensional mistake, your part could fail. For deliverable parts or for lab testing this should be a high priority.

Mass-Produce Products for the Market

Once you’re ready to take your device full-scale, we’re here to help. We can machine the mold for an injection molding machine, and run the machine to produce units for you. We have the capability to make millions of units each year, so we’ll never be the bottleneck for your operation.

Thanks to our advanced organization and engineered systems, we can quickly turn around an order and get it sent to you. Nothing will be lost in transit as parts move around our facility. At the end of the day, you’ll receive a container of high-quality, high-precision medical devices.

We Are a Reliable Partner

As your operation matures, grows, and shifts, we’re here. We like to position ourselves as a partner for all of our customers, not just an ordinary manufacturing shop. We handle everything from prototyping to mass-produced parts.

We also have a wide offering of services. This allows you to get everything done under one roof, saving time and money on your project.

Get More Out of Your Prototypes

Medical devices can be rough to prototype. It might look fine as a 3D model on your screen, but it’s hard to tell how well the device will work until you’re holding it in your hand. During the prototyping phase, you’re likely going to iterate the design a number of times, tweaking it with each iteration.

If you don’t want the prototype phase to drag on, you need a manufacturer that can keep up and expedite the process. With our 3D printers and CNC machinery, we can make that happen. Our team will turnaround new iterations as soon as possible, typically with just a few days between receiving the design and you receiving the prototype.

Enjoy Our Production and Finishing Capabilities

Medical devices often have to go through a number of different finishing steps. At Rapid Axis, we offer glass beading, anodizing, electroplating, powder coating, and painting. We will put your logo on each device if that’s needed — all you have to do is tell us the specifications, and we’ll get it done.

When you need versatility, quality, and partnership, you can turn to our expert team at Rapid Axis for all of your manufacturing needs.