Rapid Axis for FDM Printing

Rapid Axis provides competitively priced, quality parts; quickly. With a full line up of Stratasys FDM machines at our disposal we can provide high resolution and reliable FDM components in almost any industrial grade material. We quote quickly and are used to demanding lead times in our FDM service line.

Why Rapid Axis is the best choice for FDM

Our machine lineup means consistent quality on FDM parts, not just in prototype but also production. We support most industrial grade materials as well as post processing and other second operations such as finish machining or hardware installation. We can offer inspection as required on FDM components and strive to provide the best quality possible. Our operators can address build issues prior to orders and make recommendations both on orientation or design if required. We offer best in industry customer support both before, during and after the project is completed. Rapid Axis is the best choice for your next FDM project!

Production grade materials

Short lead times

Best in industry customer service

Technical

General Tolerances: Typically +/-.007 for the first inch, +/-.002” for each inch after

Resolutions: .005, .007, .010, .013, .020

Build Size: 36” x 24”x 36”

Finishing and 2nd Operations: Post op machining, hardware installation, painting and more

See Finishes page

Equipment: Stratasys

Materials: ABS ESD7, ABS M30, ABS M30i, Antero (PEKK), ASA, Nylon 12CF, PC, PC-ISO, TPU92a, Ultem 1010, Ultem 9085

See Materials page

What is FDM Printing?

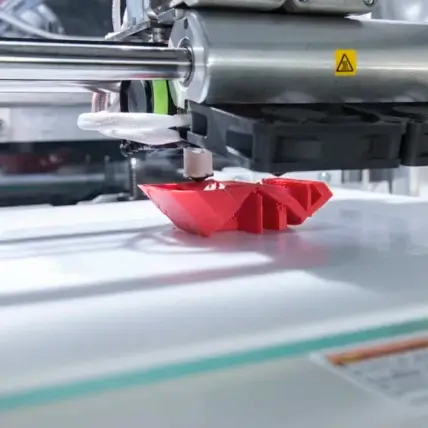

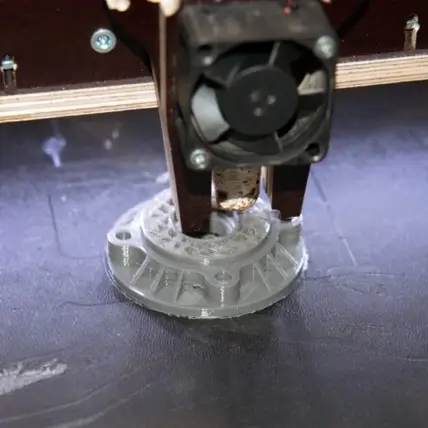

FDM or Fused Deposition Modeling is a style of 3D printing. For the everyday person, this is the type of 3D printing that they’re most familiar with. It builds layers of molten plastic together to create a 3D part.

With FDM printing, there’s a tube that feeds a roll of plastic into the extruder head. The plastic on the roll is cylindrical, so it looks like a spool of wire. As the plastic goes to the extruder, the heating element brings it above the melting temperature of that plastic. The plastic melts and gets pushed out of the extruder, called the hotend.

The head is also on a 3-axis gantry. It moves in the x, y, and z directions. Each layer is built on the xy plane, meaning the head prints the full layer at the same height. Once one layer is done, the head moves up a little bit, then stays at that new height and prints a new layer.

This process repeats until the full part is printed. The plastic cools pretty quickly as it gets laid down and exposed to the air around it. This means that you won’t have to wait for a part to cure or harden — once the FDM printer is done running, the part is ready to go.

By making a part this way, a lot of things are happening: the designer gets a lot more freedom, the parts are created quickly, each unit costs very little money, and parts can be fully customized and produced.

FDM Printing Applications

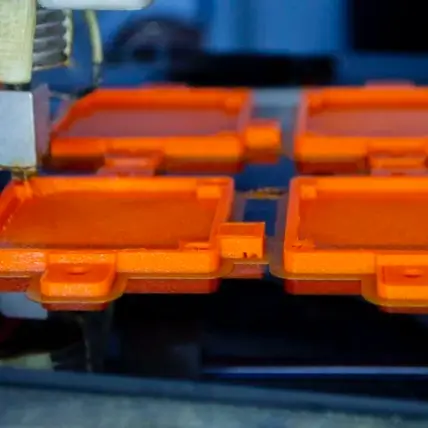

We mentioned that FDM printing is a consumer-level style of printer. However, the machines we have at Rapid Axis offer an industrial-grade alternative to these home-use desktop units people are used to. They can print with higher precision and handle more materials, giving them even more advantages when it comes to fabrication.

Quickly Make Prototypes

It’s no exaggeration, 3D printers create products incredibly fast. You could realistically go from a 3D design to a physical unit within a few hours. Larger, more accurate parts are going to take longer to print, but they’re still made much faster than parts on a CNC machine.

This makes iterative prototypes much easier with an FDM printer. Since this option is one of the least expensive, you can create low-cost products in no time. These models can be used in a number of different applications.

As you get feedback from the part, you can change the design and come to us for yet another prototype. This process can continue until you have a design that’s ready for full-scale production.

From there, you’ll want to go with injection molding or CNC machining. However, 3D printing will do all of the heavy lifting during the beginning phases of your project and depending on your application it may be suitable for production in FDM.

Choose From Dozens of Materials

FDM is one of the most versatile 3D printing options when it comes to material choices. Since the technology is so simple, it’s just a matter of finding a thermoplastic that melts at a temperature lower than the hotend can achieve.

Popular FDM printing materials at Rapid Axis include ABS, ASA, PC, Nylon, PEKK, and Ultem. There are also a number of options that offer aesthetic upgrades such as paint, polishing or sanding.

A strength of FDM is that the materials are all production grade. You know you’re getting the chemical equivalent of an injection molded part in the same material.

Fully-Customize Your Parts

3D printing might be the most versatile way to manufacture a part. Parts can also have geometries and external or internal features that traditional manufacturing processes cannot complete.

An excellent example is a recent project with an Anterro (PEKK) structural joint that filled a Fortus 900 platform. The same project being machined on a 5-axis CNC machine would have taken four times longer and cost that much more but still would have had to have features omitted from the build. With FDM, it was as simple as loading the file into our machine and building then removing the support structure. Regardless of complexity as long as the part is printable, it’s as simple as transferring the model into our printer and setting up orientation.

Print Virtually Anything

The bottom line is that an Fused Deposition Modeling machine can print virtually anything as long as supports are taken into consideration.

If you can imagine it and draw it in a CAD model, there’s a good chance that our team at Rapid Axis can print it. Larger items allow for more details, so you’ll have to remember that while it’s being designed. Smaller parts typically have a worse resolution.

How does this apply to your operation? Since FDM printing is so open-ended, there are probably tens of areas that could be improved with the help of an FDM-printed part. If you reach out to our experts, we’ll help you understand what FDM printers can do. From there, your eyes will be opened and you’ll notice different parts of your process that might benefit from an FDM print.