Rapid Axis for SLA Printing

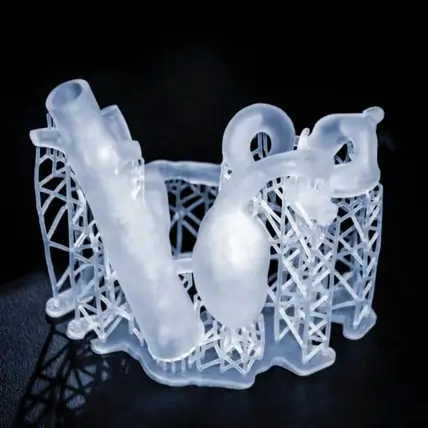

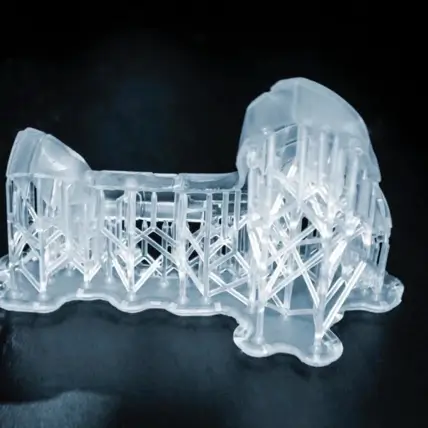

Rapid Axis provides competitively priced, quality parts; quickly. With both hi resolution and large format SLA Machines at our disposal you can send us projects and parts of any size or application from catheter tips to robotic arms, we can support it. Rapid Axis keeps most commonly processed materials available on demand from the Somos and Accura material lines. We quote SLA quickly and can turn parts typically in a matter of days.

Why Rapid Axis is the best choice for SLA

Our machine lineup means consistent quality on SLA parts, not just in prototype but also production. We support most industrial grade materials from Somos and Accura as well as post processing and other second operations such as finish machining, painting or hardware installation. We can offer inspection as required on SLA components and strive to provide the best quality possible. Our operators can address build issues prior to orders and make recommendations both on orientation or design if required. We offer best in industry customer support both before, during and after the project is completed. Rapid Axis is the best choice for your next SLA project!

Short lead times

High resolutions

Large material selection

Technical

General Tolerances: +/-.007″ for the first inch, +/-.003″ for every inch after

Layer Thickness: .002” to .006” resolutions

Build Size: 29” x 26” x 21”

Cosmetics: Build in clear, sanding, dyeing, painting

2nd Operations: Post op machining, hardware installation, split and bond

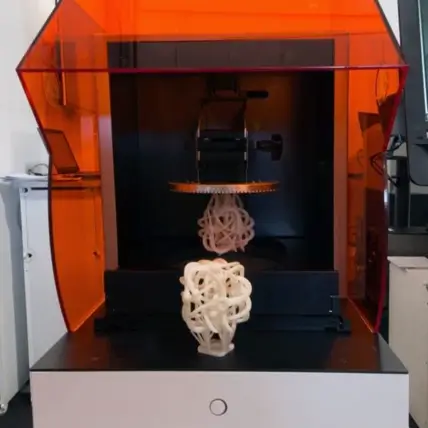

Equipment: 3D Systems

Materials: Accura 25, Accura 60, Accura Xtreme, Somos 9120, Somos Bioclear, Somos EvoLVe128, Somos Taurus, Somos Watershed Black, Somos Watershed XC11122

See Materials page

What is SLA Printing?

Not to be confused with SLS, SLA printing stands for Stereolithography. An SLA printer uses a vat of liquid photopolymer. That’s a scientific way to describe a light-sensitive liquid. Under exposure to visible or ultraviolet light, the liquid in this vat wants to change its state and become solid.

There’s a laser in each SLA printer that gets shone against a scanning mirror. The mirror will make slight movements around, and the laser will subsequently change direction and hit different parts of the liquid photopolymer vat.

Once the laser comes in contact with the liquid, it will start to solidify the liquid. The build platform then moves further from the laser, and another layer is built. This continues until the entire 3D part is made.

It takes further exposure to UV light for the part to solidify and entirely cure. For harder and more thermally resistant units, the finished part might need to go through a UV treatment.

The liquid used in the vat translates to what material the part is made out of.

As you might imagine, SLA printers have features from different types of 3D printers that we offer at Rapid Axis. It seemingly borrows concepts to allow parts to be versatile, low-cost, fast, and highly accurate. Believe it or not, SLA printers are one of the first additive manufacturing machines invented, so all subsequent printers take ideas from the SLA platform.

SLA Printing Applications

There are a lot of industrial applications for SLA-printed parts. Understanding the major benefits of SLA printing will help you decide when to use it and how it can help your operation.

Material Selection

SLA printing offers the second-most options when it comes to choosing a material. You can pick from dozens of engineered materials that create strong, flexible, and/or reliable parts. Each material selection offers a different range of physical properties. This gives you the ability to hand-select the functionality of your printed part.

From a manufacturer’s perspective, the selection doesn’t make a big difference. It’s just a matter of loading the right liquid into the vat, so don’t let a printing shop tell you otherwise.

With more material options, you can solve a wider array of problems with SLA-printed parts.

Good Aesthetics

Something we like about SLA-printed parts is that the aesthetics are impressive. We have a lot of customers who want an SLA print to showcase a new design or demonstrate the use of a new product. If the part looks rough and unappealing, you could lose stakeholder support or consumer interest.

Since SLA-printed parts look very impressive off of the printer, you’ll have a better experience showcasing the unit. This is even more important if you’re using an SLA printer for a production unit.

There are post-processing options to finish a part and make it look like a production unit. This can be time consuming and will add to pricing and lead time. Painting, sanding, dyeing of SLA parts are all options. It is easier to paint an SLA part than pieces from most other 3D Printing methods.

Impressive Prototyping

We mentioned that people might use SLA printers for prototyping. In reality, this is one of the best manufacturing methods to get usable, working models.

With prototyping, you’ll often need to iterate a design, test the new design, and repeat the process. There are very few products that we’ve seen that don’t go through a few rounds of prototyping.

With SLA printing, this whole process becomes easier. Since we’re essentially printing directly from your 3D model, you can quickly change a design and send it back to us for a print. The printing process is quick, so we can return it and allow you to expedite the prototyping phase.

Doing the same process with traditional CNC machines might take extra weeks or months. On an injection molding machine, it’s simply not possible to change the design and tweak the part. To put it simply, 3D printing is the best option, and SLA printing is a great choice under that umbrella.

A Low-Cost Option

In general, 3D printers are less expensive than traditional machining. With SLA printers, the operating cost and raw materials are even more inexpensive (as compared to MJF, SLS, or DMLS). You don’t have to spend a lot of money to create a high-quality, production-grade product on an SLA printer.

Our experts can help you choose which 3D printing option is right for you, all you have to do is reach out and explain your application. At this point, we’ve 3D printed tens of thousands of units, and we would be honored to help with your project as well.