Rapid Axis for Production and Prototype CNC Machining

Rapid Axis provides competitively priced, quality parts; quickly. Rapid Axis supports Engineers and Buyers with their machined component needs by providing consistent reliable quality, quick lead times and the best customer support in the industry. We are the subject matter experts for CNC Machining needs for projects from Prototyping to Production.

Why Rapid Axis is the best choice for CNC Machining

Rapid Axis has a superior focus on quality and customer support beyond that of your typical machine shop or service bureau. Our experience with a vast array of products from various industries makes us the best choice for your project. With a well-planned and versatile equipment format and support from a highly curated partner network, Rapid Axis the best choice for your Machining projects. With constant open capacity you can expect competitive pricing and short lead times; in addition to your drawing’s tolerances being met! We’re happy to quote both CNC Prototyping and Production.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Technical

General Tolerances: Easily +/-.002 or tighter, matched to drawing

Build Size: Milling 80”x48”x24” or Turning 32” Diameter

Finishing and 2nd Operations: Anodize, PAA + BR127, Powder Coat, Paint, Chem Film, Alodine, Chromate, Heat Treating, Black Oxide, Zinc Plating, Polishing, Bead Blast, Electropolish, Gold Plating, Silver Plating. Brushing, Vapor Polish, Teflon Impregnation, Park Marking, Logo Work, Hardware Installation, Assembly and more

See Finishes page

Equipment: HAAS, FADAL, CONQUEST, OKUMA and more

Materials: ABS, Acrylic, Aluminum, Copper, Bronze, Brass, Delrin, FR4, Garolite G10, HDPE, Inconel, Magnesium, Metal, Noryl, Nylon, Polycarbonate, PEEK, Plastic, Polypropylene, PTFE, Stainless Steel, Steel Alloys, Titanium, UHMW PE, PVC, Zinc and more

See Materials page

What is CNC Machining?

Computer Numerical Control (CNC) machining is one of the most popular forms of manufacturing today. In this method, the machine uses computers to expedite the process and make everything more precise.

A CNC machine is a general term. It can refer to milling machines, plasma cutters, grinders, lathes, and drilling machines. The key is that all of these machines use a computer and program to help position, move, and run the machine.

Machines that don’t have CNC capabilities will require the machinist to place, move, and run the machine through a series of levers and wheels. CNC machines can be moved by pressing buttons on a screen, dialing in coordinates, and running programs.

As you might expect, the addition of CNC on a machine makes it much faster and more precise.

Compared to other manufacturing options, CNC machines are fast, inexpensive to run, accurate, repeatable, customizable, and allow for the fabrication of hard materials like metals and plastics.

Different Types of CNC Machining

Rapid Axis supports various CNC Machining fabrication methods such as 3, 4 and 5 Axis Milling as well as Turning and other methods. See below to learn more.

CNC Milling

With unique equipment formats and 3, 4 and 5 Axis milling capabilities Rapid Axis is an easy choice for CNC Milling. Our offering of competitively priced, quality parts; quickly will keep Rapid Axis on your supplier list year after year. Almost no project is a “no quote” and we can build components both large and small.

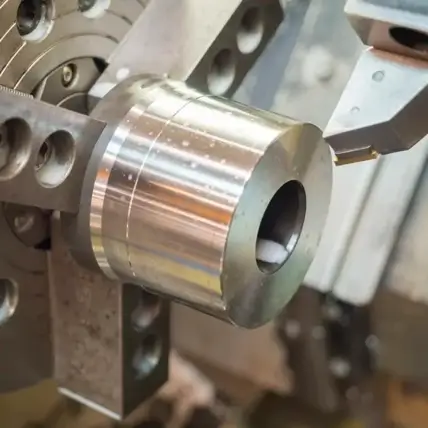

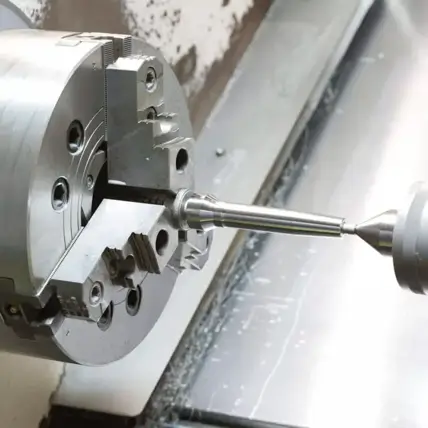

CNC Turning

With unique equipment formats and high speed turning capabilities, Rapid Axis is an easy choice for CNC Turning. With our custom turning capability we can deliver any project, on time and under budget. Most of our turning centers feature live tooling for milling and drilling rather than utilizing secondary operations.

CNC Machining Applications with Rapid Axis

There are a lot of reasons why people choose CNC machining. Compared to other forms of manufacturing, there are plenty of typical applications where CNC machines stand out.

Rapid Prototyping

Rapid Axis’s CNC machines are great for prototype manufacturing. Since the machine runs quickly and creates highly accurate parts, you can have a functional prototype created in days.

CNC machines tend to make pieces in production-grade metals or plastics, so the prototype you get will be fully operational. You can run tests, prove out the concept, and use the part for presentations within your business.

If you need to iterate the design and get another unit made, Rapid Axis’s prototype CNC machining can help with that as well.

Production-Grade Units

As we mentioned, CNC machines can operate on almost all production-grade materials. Machines can run plastics and metals that offer better material properties than other manufacturing processes.

End use product can exactly replicate your requested material properties and tolerances. After programming is completed, repeatability is there and production runs from the hundred to thousands becomes possible.

You can take a fully finished and inspected CNC machined part fabricated by Rapid Axis and install it in your assembly for end-use without issue.

Small-Batch Products

In general, people tend to pick injection molding for large-batch products and CNC machining for small-batch products. CNC machines can make dozens of nearly identical parts in a short period of time. Once the program is created on the machine, it’s easy to put in new material and run it again, creating another unit.

CNC machining starts to fall off as you consider batches over 100 units in cases where the component is suitable for tooling. In larger batches, CNC machines can use nesting programs and pallet feeders to increase quantity delivery and economics. Up until the point that a tooling investment becomes economical, CNC Machining is usually the preferred method of fabrication.

Regardless of the quantity if you need strong, reliable parts — especially ones made out of metal — then CNC machining is the right choice.

Fully Customized Parts

One of the biggest applications for CNC machining is creating fully customized parts. In most cases, all it takes is a 3D CAD model. From there, dimensions can be pulled in order to create a real-life version of what you designed on the screen.

The best practice is to make 2D dimensioned sheets of the part and call out critical dimensions as well as 2nd Operations. It’s not always necessary as many prototypes can be fabricated simply from 3D CAD but if you want to see the full quality Rapid Axis has to offer, this is the way to go.

With multi-axis CNC machines, intricate features can be created with no problems. This makes the design process even easier and allows you more freedom when it comes to creating customized parts. If you have questions about your component’s design reach out to one of our representatives.

Strong, Reliable, and Durable Products

CNC machines can craft strong, reliable, and durable parts. It’s partially due to the better material selection you have than other processes — since you can use materials like aluminum, stainless steel, and titanium alloys.

CNC machines cut away from a solid block of material. The inside features stay intact, allowing the part to deal with stresses and pressure better. In 3D printing or other methods, it’s common for a lattice-like or hollow geometry to fill the inside of a part (so the part can be made faster and cheaper). This lattice isn’t nearly as strong as the solid internals of a CNC machined part.

Create High-Precision Parts

In Rapid Axis’s precision machine shop, parts can be made to hit minuscule tolerances (scroll down to see for yourself). We can routinely hold half thou tolerances on both flat and cylindrical surfaces. The secret is in-process inspection to make sure components and features are measured during fabrication.

Rapid Axis validates parts when requested via FAI or CMM. We guarantee all CNC machined parts are built to specification.