Rapid Axis for CNC Milling

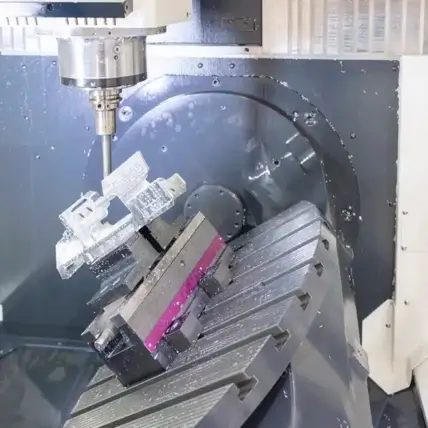

With unique equipment formats and 3, 4 and 5 Axis milling capabilities Rapid Axis is an easy choice for CNC Milling. Our offering of competitively priced, quality parts; quickly will keep Rapid Axis on your supplier list year after year. Almost no project is a “no quote” and we can build components both large and small.

Why Rapid Axis is the best choice for CNC Milling

With consistent reliable quality, excellent pricing and best in industry customer service Rapid Axis is the clear choice for your next CNC Milled parts. With a unique equipment format we can support jobs of almost any size or complexity. We offer free 1st Level Inspection on all projects and quotes to match print without blanket statements about loosened tolerances. With no qty minimum and quick lead times we can take you from prototyping to production for any milling project. Our best in industry customer service and competitive pricing will keep you coming back for everything from a simple plate with counter bores to a 5 Axis structural joint.

Parts made to match customer tolerances

Finishing and second operations supported

3, 4 and 5 Axis Milling supported

Technical

General Tolerances: Easily +/-.002 or tighter, matched to drawing

Build Size: 80”x48”x24”

Finishing and 2nd Operations: Anodize, PAA + BR127, Powder Coat, Paint, Chem Film, Alodine, Chromate, Heat Treating, Black Oxide, Zinc Plating, Polishing, Bead Blast, Electropolish, Gold Plating, Silver Plating. Brushing, Vapor Polish, Teflon Impregnation, Park Marking, Logo Work, Hardware Installation, Assembly and more

See Finishes page

Equipment: HAAS, FADAL, CONQUEST, OKUMA and more

Materials: ABS, Acrylic, Aluminum, Copper, Bronze, Brass, Delrin, FR4, Garolite G10, HDPE, Inconel, Magnesium, Noryl, Nylon, Polycarbonate, PEEK, Polypropylene, PTFE, Stainless Steel, Steel Alloys, Titanium, UHMW PE, PVC, Zinc and more

See Materials page

What is CNC Milling?

Milling is a specific type of Computer Numerical Control (CNC) machining. That means that it uses computers to automate most of the processes and increase the precision. With a non-CNC mill, the machinist would need to manually measure, move the machine, and make every cut.

With the addition of CNC capabilities on a mill, programs can be made that completely automate the fabrication of a part. With Rapid Axis’s more complex CNC mills, tools can even be changed out and the only human interaction would be loading material and hitting “run” on the machine. This allows for greater fabrication speeds through automation.

Our CNC mills have interchangeable heads and move in multiple different directions with a computer readout that gives information about the location and cutting path. With the addition of 4 and 5-axis trunnions our machines will allow the cutting tool to rotate as well as move in the three linear directions meaning that highly complex parts can be done in one run without multiple setups.

People tend to choose CNC milling for projects that require high precision, quick turnarounds, and superior quality.

CNC Milling Applications

In our experience, CNC milling is one of the more versatile applications that a machine shop can offer. Customers have chosen CNC milling from Rapid Axis for a number of different reasons.

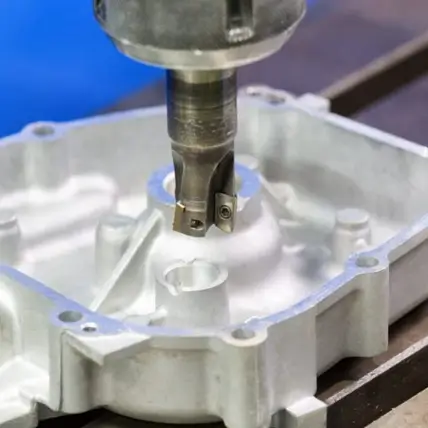

Creating Complex Parts

Above everything else, CNC mills are great at fabricating complex parts. This is especially true for the 5-axis machine we have onsite. Since the head can rotate while cutting, rounded features and internal pockets can be easily made without needing to remove and reposition the material.

There have been times when customers provided multi-sheet 2D drawings that had a number of sections, detailed views, and complex features. With the addition of a STEP file, despite complexity, we had no problem machining these parts thanks to our high-quality CNC milling machines and expert machinists.

Choose From Lots of Materials

CNC milling largely incorporates metals and hard plastics. At Rapid Axis, we have dozens of different materials to choose from.

Rapid Axis carries most market available and commonly used materials. Though we can also order materials with typically a two day turnaround time.

High-Quality Prototyping

When you’re introducing a new product or trying to upgrade your current operation, prototyping is a necessary step. With CNC Milling you will obtain parts built to the tolerances specified on your control drawings and can rest assured knowing the component came out as designed.

CNC milling allows for higher-quality prototyping than say 3D Printing, since mills can use a wider array of materials than 3D printers can and rigidity during fabrication increases tolerances.

Fast Short-Run and Production Fabrication

With CNC Milling automation is the name of the game. If you’re looking for tens, hundreds or thousands of units, our machines with pallet feeders and/or nesting programs can save you an immense amount of time and money.

With CNC milling, you can have dozens of dimensionally near identical parts within a matter of days all cut from the same program and materials.

At Rapid Axis, one of our big focuses is providing the highest-quality products in the shortest turnaround times. With automated CNC milling, this becomes much easier for us.

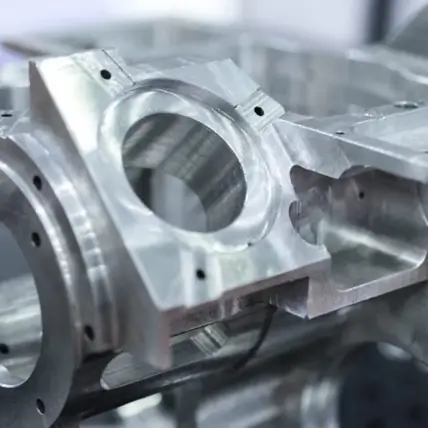

Production-Quality Units

We have customers who come to us for production items. These are parts that will get installed directly onto the operation and will be used for as long as the equipment is running. We’ve provided items like a shroud, bracket, bezels, or full mechanical assembly for our customers over the years.

All of these products need to be high-quality, made from the right materials, and need to meet the dimensional specification of our customers. For plenty of our projects, we utilize the CNC mill since it can check all of the boxes easily.

We also offer finishing steps that will further improve the quality of our machined parts. That means that you’ll receive production-quality units that can be installed directly onto your process without any problems.

Overall Design Versatility

A typical CNC milling machine can handle dozens of different actions. It can cut parts to the correct overall dimensions, machine pockets, create rounded or angled features, and drill precise holes in parts.

Simply put, CNC mills offer design versatility that you can’t get with other manufacturing methods. On the drafting table, you can take many more liberties if you’re designing a milled piece. With more freedom, you can ensure the design hits all of the requirements and meets the “wants” for your project. There’s no need to omit certain features that would otherwise help your process (unless you’re designing to keep the cost low).