Rapid Axis for Waterjet Cutting

Rapid Axis provides competitively priced, quality parts; quickly. With unique equipment formats and types Rapid Axis has capability of cutting both thin and thick materials via Waterjet. Whether you have a one off prototype or a flat pattern for a production run, Rapid Axis can help. If your flat pattern requires forming operations, hardware installation or finishing Rapid Axis has the capability to support it all.

Why Rapid Axis is the best choice for Waterjet Cutting

With quick lead times and attention to part quality and tolerances Rapid Axis is the clear choice for your next Waterjet project. We’ll quote your components quickly, competitively and in spec and provide post order support as well. Rapid Axis can support many custom material requirements for Waterjet as well as second operations and inspection levels. See why Rapid Axis is known for best in industry customer service and try us out for your next Waterjet project.

Quick lead times

Excellent customer support

Vast material selection

Technical

General Tolerances: +/-.030” or better is typical and dependent upon material

Thickness: Waterjet can cut some materials up to 3.00” thick

Table Size: 174” x 30”

Materials: Sheet or Plate Plastic, Metals or Fabrics

See Materials page

What is Waterjet Cutting?

Waterjet cutting is another modern form of sheet metal manufacturing. It has a lot in common with laser or plasma cutting machines.

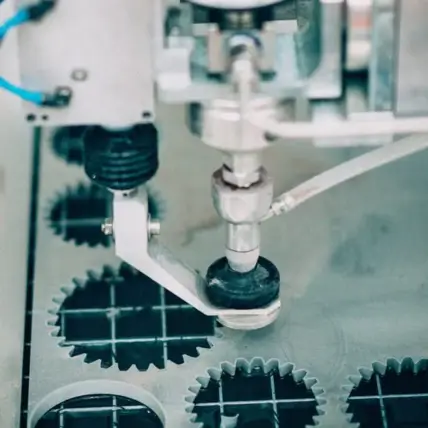

A waterjet cutter is a piece of automated equipment which can be programmed similarly to a CNC machine to run a route. Once programmed the cutter itself runs the cutting operation with minimal interaction from an operator. In the case of waterjet cutters, the CNC portion does almost all the work — all we have to do is load the material and set the program.

As the name suggests, a waterjet cutter uses a constant, high-pressure jet of water to cut through sheet metal. You can think of it like a pressure washer on steroids. The cutter has a program that tells it exactly where to go, and a 3-axis gantry controls the path.

On the gantry is the cutting head. The waterjet cutter is attached to the gantry and faces the table underneath. The loaded material stays stationary under the cutter, and only the jet moves in the x, y, and z directions.

The power has so much force that it can cut through metal plate up to 3” inches thick.

Waterjet Cutting Applications

Is waterjet cutting the right choice for your next sheet metal project? Here are some major benefits and applications of this fabrication method. After going through this section, feel free to reach out to our experts at Rapid Axis and we can help you make the decision.

It Cuts Very Quickly

Waterjet cutters are very fast. The cutting head moves quickly around your material, and it can keep going with very little downtime.

There’s no comparison when it comes to speed between waterjet cutters and CNC milling machines. The mills are still quick, but waterjet cutters are exponentially faster.

Since there’s a constant supply of water, the only factor that limits the speed is the thickness of the part and how accurate you want to be. We always prioritize accuracy, so we’ll slightly lower the speed, but we can still create hundreds of parts on a single waterjet cutter in one day.

Can Work on Multiple Materials

You can load almost any metal and cut it with a waterjet cutter. Even stubborn materials like titanium have been cut by our waterjet cutting machine. The best part is that we achieve the same high quality and precision on every part we cut, regardless of the material used.

We spend some extra time upfront to ensure all the parameters are filled out for our machine. Part of that is specifying a thickness and material option. Doing this ensures the cutter moves at the right speed to get the best cut across the whole part.

The Water is an Eco-Friendly Option

Another thing to love about waterjet cutters is that they’re an eco-friendly option when it comes to machining. Since water is used for the operation, you don’t have to worry about noxious off-gassing or pollution from the machine.

It also helps that we recycle most of the water used on our machine. It goes through a quick treatment and decontamination process before getting reused.

Non-Toxic Exposure to Your Parts

Water is also a great choice for cutting parts because there’s no risk of contamination or toxic transfer to your part. Water is safe to use on almost any sheet metal surface. With some other cutting methods, there are incompatible materials that will get damaged through exposure to the cutting product used.

With waterjet cutters, there’s no need to treat or clean the part after, since only water was used. We still go through to make sure the part is smooth and dried before packaging and shipping it, though.

Can Cut Various Thicknesses

As we mentioned earlier, waterjet cutters can cut through materials up to 3 inches thick. This means that the same machine can handle ten different parts of ten different thicknesses.

You can design your sheet metal assembly how you would typically do it, and allow us to worry about cutting it. There’s no need to stick with a single thickness across your design if you don’t want to.

We tell our machine what thickness of material is being cut. This will change some key characteristics of the cutting profile, resulting in a perfect cut each time. Thicker materials take a little longer to cut, but it’s still faster than milling the same part.

Parts are Easy to Design

Designing a part to be waterjet cut is surprisingly easy. As a designer, you don’t even need to make a 3D profile. You can just draw a series of lines in 2D space and allow us to transfer that into a cutting program.

After all, the machine is just cutting a certain path out of the material under it. It can create internal notches and geometries as well as external part outlines.

Since waterjet cutters are so versatile, they’re not like stamps or die cutters. Those are constrained to making a single shape every time. Waterjet cutters can make a dozen completely different shapes back-to-back without any worries.

Imagine drawing shapes on a piece of paper with a pen. That’s almost how a waterjet cutter works in application. Instead of a pen, imagine a high-velocity stream of water cutting out your pen’s path.