Rapid Axis for Steel Sheet Metal Fabrication

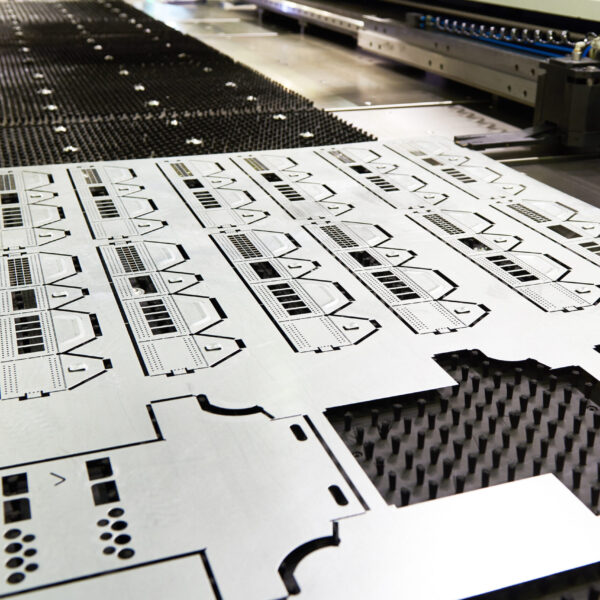

Steel sheet metal fabrication is one of our more popular options at Rapid Axis. As a full-service machine shop, we work with a lot of different materials, which is good news for any engineer looking for a long-term manufacturing partner.

Steel sheet metal is a versatile material that’s easy to work with, and it’s often more affordable than stainless steel parts. With the right finish, it offers excellent durability and long-term performance, making it ideal for a wide range of applications.

Our team can help you design your parts and choose the best finishing option so your project stays strong and problem-free for years to come.

Why Choose Rapid Axis for Steel Sheet Metal Parts?

At Rapid Axis, we are experts when it comes to steel sheet metal parts. We have a number of finishing options to choose from to ensure each of your parts is perfect.

We have all of the machinery, personnel, and experience required to deliver high-quality steel sheet metal parts. We also offer quality assurance processes to make sure every part is perfect before it gets to your loading dock.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

We have a few steel options to choose from for your next sheet metal project:

Cold rolled steel (CRS)

One of the two most common options. CRS has a smooth surface and it’s great for enclosures and housings.

Hot rolled steel (HRS)

HRS is slightly less formable than CRS, but boasts greater strength, weldability, and affordability.

Galvanized steel

This option is zinc-coated which adds even more corrosion resistance to each part.

High strength low alloy (HSLA)

HSLA can require specialty tooling, but is a stronger and lighter option than CRS or HRS.

Finishing Options

As a full-scale machine shop, we have a range of finishing options for you to choose from. While we offer a lot more than what’s on this list, these options are ideal for steel sheet metal fabrication:

Powder Coating

Powder coating is probably our most popular option for carbon steel projects. As you know, carbon steel is more prone to rusting, and a powder coating finish can help prevent that. This process involves spraying your sheet metal parts with an aerated powder, curing it in an oven, and leaving it to dry. The result is a coating that is chemically bonded to the part, boosting the part’s aesthetics and performance, as well as preventing rust.

Bead Blasting

Beat blasting is another way to delay corrosion. Some corrosion starts as tiny divots, or pits, in your sheet metal. Bead blasting is a process where we shoot tiny pellets against your part to smooth out the surfaces. This tamps down parts and removes pits, also creating a matte and more uniform finish.

Galvanization (Post-Fab)

If you don’t opt for galvanized sheet metal as a stock material, you can always galvanize the finished part or assembly after the fact. This post-fabrication galvanization adds or strengthens the zinc coating on your part, which really helps with rust protection.

Painting

If you want to keep it simple, we can also apply a liquid coat of paint for protective or cosmetic purposes. It’s good for color-matching parts without the added time and cost associated with powder coating.

Key Features

Mild steel sheet metal has a few key features that are worth mentioning:

- High strength and rigidity. Steel is naturally strong and rigid, making it an excellent choice for demanding applications. The same material that supports massive warehouses in thick beams also delivers impressive strength when used in sheet metal form.

- Excellent weldability. Steel combines strength with the ability to be easily welded. While it takes a bit more skill than aluminum, it remains one of the most straightforward metals to weld.

- Easy to machine and bend. Generally speaking, steel sheet metal is easy to manufacture across the board. We can machine and form (bend) it easily, and plasma cutters make the work look easy.

- Cost-effective option. Compared to stainless steel, mild steel is a more cost-effective option with similar material properties.

General Restrictions

However, there are also some restrictions to keep in mind during your next sheet metal project.

- Tolerances. In general, we can hit tolerances as low as ±0.005” to 0.010”, which is on par with most high-quality machine shops in the country. The thickness and complexity of your steel sheet metal build can change the tolerances we can hit.

- Part size limits. Your steel sheet metal parts are also limited by the table size of our plasma cutters and waterjet cutters. Reach out to us directly to get an updated size limit.

- Weight considerations. Steel is a lot heavier than aluminum and titanium, so keep in mind that steel sheet metal is going to weigh more. As parts get bigger, you’ll need to think about handling and transporting them.

Applications

When might you choose steel sheet metal over other metal options? There are plenty of examples we can think of, and most major industries use some form of steel sheet metal.

Automotive

Automotive projects use mild steel all over the place. The frame, chassis, and reinforcement brackets often use mild steel instead of stainless steel. Crumple zones and panels will also use mild steel since it’s more affordable.

Aerospace

Aerospace and defense projects will opt for steel sheet metal to create protective housing and structural brackets across their vehicles. In addition, mounting plates and reinforcement plates can be made out of steel sheet metal to save time and money on manufacturing.

Medical Equipment

Since carbon steel is more affordable, medical companies can use it for shrouds, enclosures, device housings, and shielding. Other times, you might use steel sheet metal for sterilizable trays and panels.

Industrial Machinery

Within industrial applications, there are a million reasons to use steel sheet metal. The most common examples are machine guards, safety panels, access doors, and enclosures. The sheets are often powder coated or galvanized to help each part last longer.

Energy and Infrastructure

There are also a lot of energy applications for steel sheet metal fabrication. You can make solar panel mounts or battery housings out of steel sheet, or you can make a variety of HVAC frames and ducts. The low cost and great manufacturability make mild steel a good choice.

Consumer Products

With a nice powder coating or layer of paint, steel sheet metal can be used within household appliances, shelving brackets, framework components, storage systems, and much more.