Rapid Axis for Stainless Steel Sheet Metal Fabrication

At Rapid Axis, we offer high-precision stainless steel sheet metal fabrication that meets the needs of your project. We’ve created stainless steel parts for various industries and countless applications, and we can help with your next project as well.

As a material, stainless steel is great to work with. It can be formed, cut, welded, finished, and assembled with ease thanks to our in-house teams at Rapid Axis. Whether you need a one-off prototype or hundreds of production-quality assemblies, our team can help. You can even upload a 3D CAD file to get started with a custom quote from our team.

Why Choose Rapid Axis for Stainless Steel Sheet Metal Parts?

The sheet metal parts we make at Rapid Axis focus on quality, turnaround time, and additional finishing steps. We do more under one roof, so you don’t need to shop around and waste your money elsewhere.

Our sheet metal projects can meet tight tolerances and clean finishing requirements. Regardless of your application and performance criteria, we can likely meet your needs.

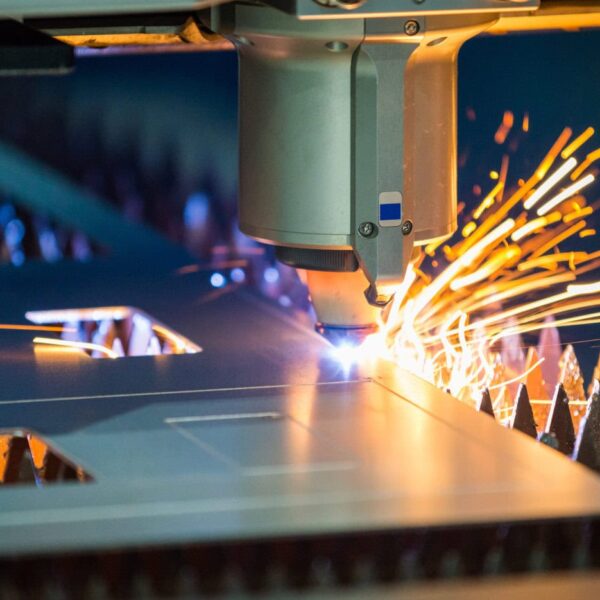

Thanks to our advanced laser cutters and bending capabilities, we can tackle your most complicated and intricate sheet metal projects. In addition, we position ourselves as a manufacturing partner, not just a one-off fabricator. With us in your corner, you’ll be able to make prototypes, iterate on the design, and get ready for production with the same manufacturer.

With our help, you can save time and money without sacrificing the quality of your stainless steel sheet metal parts and assemblies.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

As you probably know, different alloys of stainless steel have different benefits and applications. At Rapid Axis, we have a wide range of materials and alloys to choose from. Specifically looking at our stainless steel sheet metal, you can choose from:

304 Stainless Steel

Most of our projects use either 304 or 316 stainless steel. 304 is a “general-purpose” alloy that is cost-effective, easy to weld, and long-lasting. It’s easy to work with and bend, so we don’t need to spend extra time making your parts.

316 Stainless Steel

316 is the other common alloy to consider. This alloy has molybdenum added, which makes it a more chemical-resistant alloy and better at resisting corrosion. You might opt for 316 stainless if you’re dealing with marine or pharmaceutical applications.

430 Stainless Steel

430 stainless steel offers good corrosion resistance and formability and is generally less expensive. It’s a good option for decorative parts that you don’t care about the strength and want to save some money.

201 Stainless Steel

201 is another inexpensive option, but it has better mechanical properties than 430. 201 stainless steel is good for parts that don’t see a lot of force but still need to last a long time. You might use 201 for a bracket or framework that needs to be less expensive but still functional.

17-4 PH Stainless Steel

17-4 PH stainless steel goes through a process called “precipitation hardening”, which boosts the mechanical strength and corrosion resistance of the part. This is one of the more specialized alloys that we usually use in aerospace and defense projects, but it’s definitely not as common as 304 or 316 across the board. You typically only use 17-4 PH if your project has a need for high strength and corrosion resistance.

Finishing Options

As we mentioned, our shop offers a lot of additional finishing options to ensure your parts meet your functional and aesthetic needs. While we offer more options than we can list, some of our more common choices when it comes to stainless steel sheet metal fabrication are:

Powder Coating

Powder coating involves adding a layer of power to a part and baking it to fuse the layer to the stainless sheet metal. You can choose from a ton of different colors and textures to make sure the part looks perfect. Adding a powder coating finish to your part protects better against corrosion, resists damage from UV exposure, makes parts more durable, and boosts the aesthetics of your parts.

Bead Blasting

When we bead blast a stainless steel sheet metal assembly, we shoot tiny pellets against the surface of the metal. This gets rid of tool marks and makes the surface more uniform. In addition, it creates a matte finish, since the beads rough up the polished texture of the stainless.

Choosing bead blasting creates a non-reflective part and can avoid some pitting since the surface is more uniform after bead blasting.

Brushed Finish

If you think about sink faucets, you’re probably familiar with the difference between brushed and polished. A brushed finish isn’t as shiny, which makes it better at hiding fingerprints and minor scratches. We achieve this through an abrasive belt or pad, removing some of the outer surface to create a uniform finish.

Electropolishing

Electropolishing is another common option we offer for our stainless steel sheet metal parts. This process removes a thin layer of material which smooths out the plates and creates a bright and shiny finish. It also helps with overall cleanliness of your parts and can resist corrosion.

Electropolishing is very common in cleanrooms and pharmaceutical components that need to be wiped down routinely.

Custom Painting and Marking

Finally, we also offer a range of custom painting and marking services. This is done to brand, label, or differentiate your parts. Some companies opt for yellow or red when their parts are related to safety or specialized tooling. You might use custom paint jobs on housings, industrial products, or consumer-facing goods.

Key Features

In our experience, stainless steel is one of the most common sheet metal materials used. There are a lot of key features associated with stainless steel sheet metal parts:

- Formability. Stainless steel can be easily formed, bent, and rolled without compromising its strength.

- Weldability. Stainless sheet metal can be welded together easily.

- Corrosion Resistance. By default, stainless steel is great at resisting corrosion, and special alloys prevent corrosion even better.

- Aesthetic Appeal. Using stainless steel can help you achieve a clean look that’s great for industrial and consumer-facing products alike.

- Hygienic Surface. Stainless is a good choice for medical facilities, pharmaceutical operations, and cleanrooms since the surfaces are non-porous and resist bacteria. Plus, stainless steel is compatible with cleaning alcohols like isopropyl alcohol, so it can be wiped down.

General Restrictions

When you’re designing a sheet metal part or assembly out of stainless steel, keep these factors in mind:

- Tolerances. We can typically hit tolerances as low as ±0.005”. If you need tighter tolerances, it will take additional setup and time.

- Maximum Part Size. Our part sizes are limited by our laser cutters and brakes. We can generally work on parts up to 120” x 60”.

- Surface Finish Variability. Without finishing steps, raw stainless steel sheet metal will have visible scratches and imperfections. We offer a variety of finishing options to ensure a uniform appearance.

- Weight Considerations. Stainless is heavier than aluminum or titanium, so make sure you factor in the added weight when you’re making your design. However, it’s stronger than aluminum, so there is a trade-off.

Applications

When might you use stainless steel sheet metal? There are plenty of applications that we can think of across industries.

Automotive

Most consumer vehicles use at least some stainless steel. It can be used in brackets, mounts, trim components, heat shields, and parts within the engine bay.

Aerospace

Aerospace projects often use specialty stainless alloys to meet their strength and durability requirements. You can use this material for panels, structural components, and brackets across aircraft.

Food and Beverage Processing

Since stainless can be food-grade, food companies will use it for conveyors and hoppers that need to meet food safety standards.

Consumer Electronics and Appliances

Stainless has a timeless aesthetic, so a lot of consumer products will use stainless for decorative parts, housings, and control interfaces that are exposed to daily wear and tear.

Medical Devices

Medical devices use stainless steel in sterile environments. They can be used for trays and surgical equipment, as well as panels and housings used on medical devices.