Rapid Axis for Copper Sheet Metal Fabrication

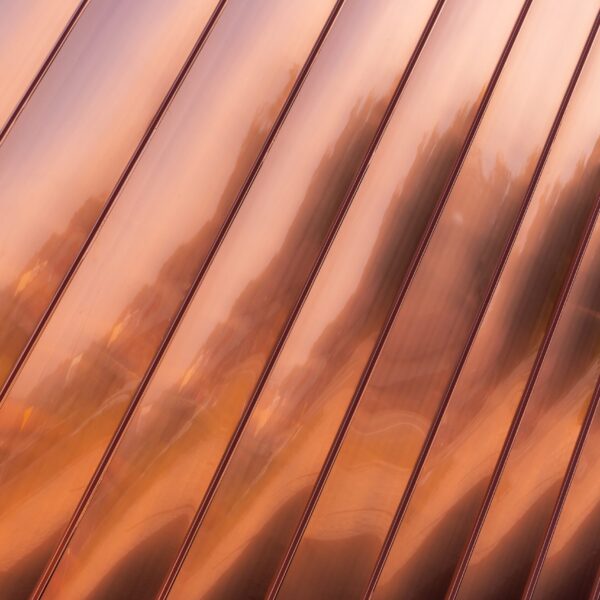

As a material, copper offers a great combination of formability, conductivity, corrosion resistance, and aesthetic appeal. This is why people choose it for both functional and decorative applications across industries.

We offer precision copper sheet metal fabrication services in addition to a number of finishing options to make sure every project turns out perfectly.

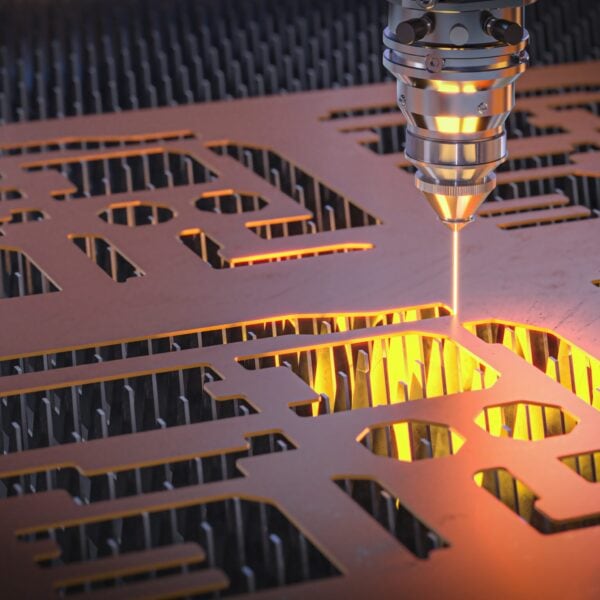

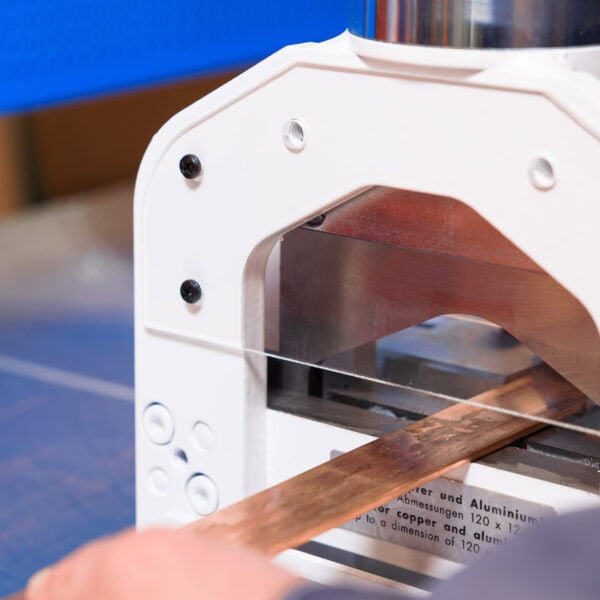

Through CNC punching, laser cutting, bending, and simple machining, we can fabricate copper sheet metal parts for your upcoming project. Whether you need a single prototype or thousands of production-quality parts, you can count on us.

Why Choose Rapid Axis for Copper Sheet Metal Parts?

At Rapid Axis, we specialize in high-quality parts that meet all of your design specifications. We offer a number of manufacturing services, and people choose our copper sheet metal fabrication when they want to receive parts that are right the first time.

Our team has hands-on experience working with copper, so we know how to get the best results. We have the right technology and expertise to exceed your expectations, and our team is always here to help.

Leverage our copper experts and get DFM support so you can avoid common copper-specific issues. Since we also offer a number of finishing steps, you can get more done under one roof.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

Copper sheet metal comes in a few different options, so you can choose the right material for your project.

C110 (Electrolytic Tough Pitch – ETP)

This is almost pure copper and has excellent formability and high conductivity. It’s ideal for electrical components and EMI shielding.

C101 (Oxygen-Free Copper – OFHC)

OFHC is ultra-high conductivity and offers incredible corrosion resistance, so it’s ideal for high-purity electrical applications. Keep in mind, it’s a more expensive option.

C122 (Phosphor Deoxidized Copper)

C122 is easier to weld and offers great corrosion resistance, but it has a slightly lower conductivity. You’ll see it used in HVAC and plumbing applications.

Brass (C260 / C272)

Brass is a copper alloy that includes zinc, making it stronger and better at resisting corrosion. It isn’t as conductive as pure copper, but it’s a less expensive option that is typically easier to work with, so you can use it for trims and decorative panels.

Finishing Options

As mentioned, we have a number of finishing options to choose from. Looking at copper sheet metal specifically, you might be interested in some of these choices:

Electropolishing

Electropolishing removes a thin layer of material from the surface of your sheet metal, so the final product is smoother and brighter. It can also make parts perform better in cleanroom environments since the surface is less likely to off-gas.

Bead Blasting

Bead blasting involves firing tiny pellets against the sheet metal to remove any surface imperfections and create a uniform face. It removes tool marks and creates a matte finish.

This helps with wear resistance as well as branding or personalization of parts.

Passivation (Optional for Alloys)

You can also passivate brass parts, which is a chemical treatment that gets rid of surface contamination. Long-term, passivation also boosts corrosion resistance. We always suggest passivation when you’re working in high-moisture environments.

Clear Coating

A clear coat on copper sheet metal works just like a clear coat on your car’s paint: it is a transparent layer that preserves the look of your copper sheet metal parts and prevents oxidation. Even though copper is corrosion resistant, it still struggles with oxidation, and a clear coat can help prevent this issue.

Custom Patinas / Antiquing

Specific to our copper projects, we offer patina and antiquing to parts. This is reserved for aesthetic purposes and involves adding aging effects and color to make your decorative parts look more unique.

Key Features

Copper sheet metal is used across industries, and there are a number of key features that make it such a great choice:

- Electrical and thermal conductivity. First and foremost, copper has incredible electrical conductivity. It can be used in electrical applications for current-carrying or shielding. Copper also provides rapid heat dissipation, so it can be used in heat sinks.

- Corrosion resistance. Copper tends to create an oxide layer instead of corroding, which makes copper a good choice for high-moisture environments where rust could be disastrous.

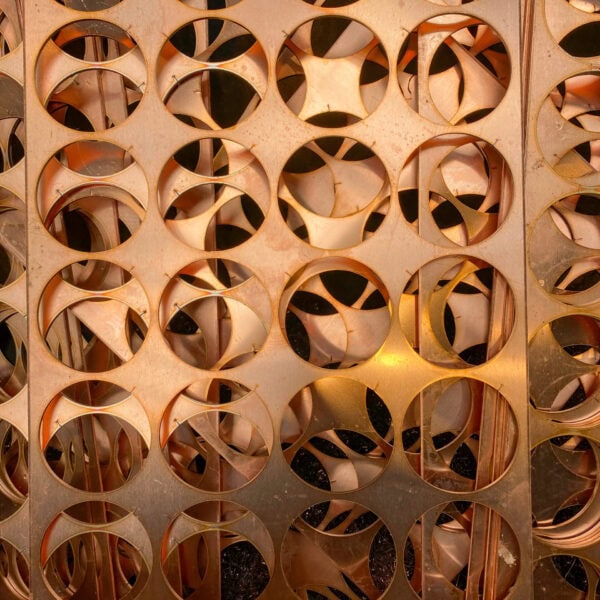

- Easy to bend and stamp. Copper is simple to work with, and we can even use stamps and sheet metal brakes to make copper parts easily.

- Appearance. Copper has a really unique look, so there are people who use it just for its aesthetics.

- Non-magnetic and antimicrobial option. Some other great things about copper are that it is naturally non-magnetic and antimicrobial, so it’s a perfect option for industrial and medical environments.

General Restrictions

However, copper has some general restrictions to keep in mind:

- Tolerances. We can typically offer tolerances between ± 0.005” and 0.010”, which is fine for a majority of projects. Feel free to reach out to us directly if you need tighter tolerancing.

- Max Part Size. Our laser cutters and brakes can accommodate parts up to 120″ x 60″ in size.

- Material strength. You should never use copper to support loads, since it is a very weak material in general.

Applications

Copper sheet metal parts can be found across industries and applications. In our experience, there are some common places where you might use copper:

Electronics and Electrical

The electronics industry is the first example that comes to mind. Anything from terminals and busbars to contacts and switches can be made out of copper. Grounding components are very commonly made out of copper. Since its electrical conductivity is so incredible, this shouldn’t be a surprise.

Aerospace and Defense

Copper can also be used in aerospace and defense projects. While copper can’t support a heavy load, it is a great choice for EMI or RFI shielding parts, heat sinks, cooling plates, conductive structures, and even antenna brackets.

Automotive and EV

The use of copper in EVs and automotive projects is more limited, but you’ll find it used around batteries and EMI shielding assemblies, plus the charging components in EVs.

HVAC and Plumbing

HVAC and plumbing use copper quite a bit. Although PEX piping is more common, you’ll still find copper piping used in a lot of different houses and businesses. In addition, copper sheet metal can be used in heat exchangers, and condenser or evaporator parts.