As you probably know, there are a lot of different ways to fabricate a part. For an engineer to make the best design, it often entails understanding which manufacturing method will be used, and designing around that method. For many, designing with sheet metal is a great way to save time in the machine shop and on the drafting table as well. How is this possible?

Our experts at Rapid Axis will explain exactly why bending sheet metal can save processing, design, and manufacturing time throughout each project. We’ll include some specific examples to help fully explain what we’re talking about.

Simplicity of Manufacturing Process

To bend sheet metal is a straightforward, simple, and highly effective process in manufacturing. On paper, it’s as simple as making a few cuts, and then physically bending metal using specialized equipment.

This simplicity is a significant time-saver, as the process involves fewer steps compared to other methods.

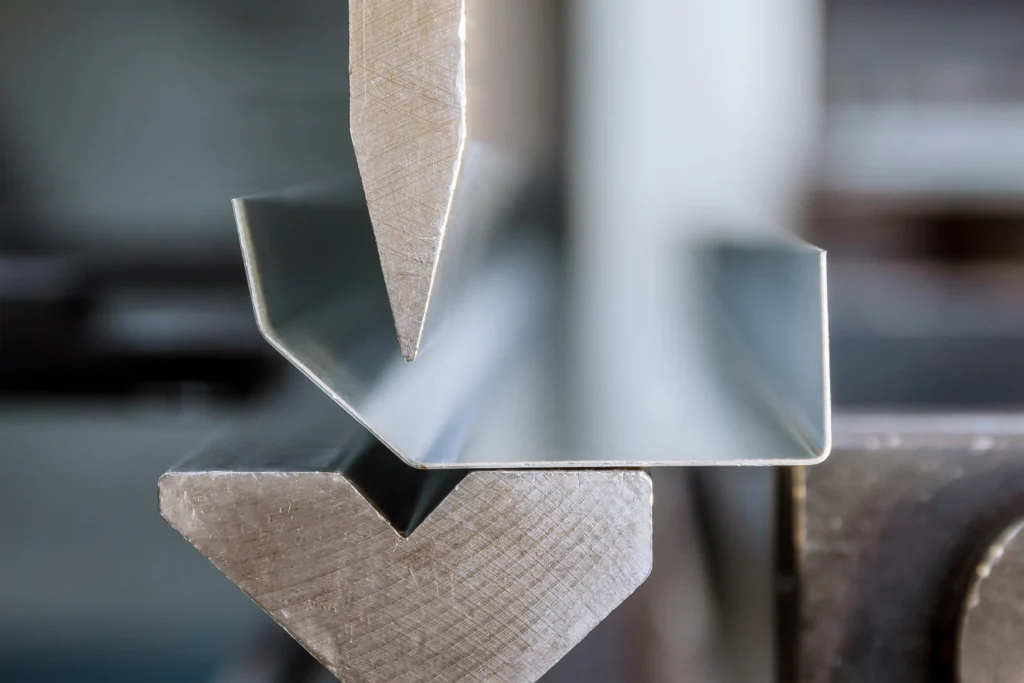

In order to bend sheet metal, a flat sheet of metal is transformed into the desired shape using a press brake or similar machinery — the specialized equipment we just mentioned. This direct approach eliminates the need for complex procedures, tooling and equipment swaps, and extensive training. Therefore, it reduces the time from design to production.

For engineers, this means quicker turnaround times for projects, allowing them to meet tight deadlines with ease. It typically also involves lower quoted costs since less time and expertise are required.

Reduced Need for Joining Methods

A key advantage of bending sheet metal is the reduced reliance on welding or other joining methods. When components are formed from a single piece of metal, you don’t need to worry about bolts, welding, or adhesives.

This not only accelerates the manufacturing timeline but also enhances the structural integrity of the part.

Fewer parts and assembly points also means fewer potential points of weakness. This leads to stronger, more reliable assemblies and parts.

Plus, the lack of required joining methods is another way to reduce overall labor costs, material waste, and turnaround times.

Faster Prototyping

In the world of engineering and design, the ability to prototype quickly is invaluable. Bending sheet metal lends itself well to rapid prototyping, allowing designers to experiment with different shapes and configurations with relative ease.

With bent sheet metal parts, you get most of the benefits of traditional CNC machining, plus the rapid prototyping that you typically only see in 3D printing.

Iterations and design tweaks can be made quickly, and new prototypes can be produced in a fraction of the time it would take using more complex methods. This speed in prototyping enables faster feedback and iteration, which is crucial in the development phase of any project.

Material Efficiency

The process of bending sheet metal is also material-efficient. Since the process can be done with minimal cuts, there is less scrap and waste produced. This efficiency not only saves on material costs but also aligns with sustainable manufacturing practices.

In an industry where material costs can significantly impact the overall budget, this efficiency is not only a time-saver but also a cost-saver.

Simplified Tooling Requirements

Bending sheet metal typically requires less complex tooling compared to other fabrication methods, as we alluded to earlier. This simplification of tools and equipment means a faster setup and quicker production runs. For projects that require a quick turnaround, this can be a crucial factor.

The general rule of thumb in a machine shop is: the simpler the design and process, the easier and less expensive it is to make. When you need to bend sheet metal, this is absolutely true.

Cost-Efficiency for Large Production Runs

For larger production runs, the cost-efficiency of bending sheet metal becomes even more apparent. The process scales well, which means that as the quantity of parts increases, the cost per unit often decreases. This scaling is especially beneficial for large projects or when mass-producing parts.

The efficiency of the process, the reduced material waste, and the simplified tooling can combine into significant cost savings over the lifespan of a project.

Consistency and Precision

Finally, bending sheet metal offers a high level of consistency and precision. Modern machinery used in this process is capable of producing parts with tight tolerances and uniform quality. This precision is essential for projects that require exact specifications and high-quality standards.

Oftentimes, our team uses waterjet cutters or plasma cutters to cut sheet metal before bending it. This equipment is incredibly precise, very repeatable, and unbelievably reliable.

Consistent quality not only saves time during the production phase but also reduces the time spent on quality control and revisions.

Contact Rapid Axis for Your Sheet Metal Bending Needs

Bending sheet metal is a time-saving and efficient process that offers numerous advantages in the field of manufacturing. Its simplicity, efficiency, and precision make it an excellent choice for a wide range of projects, particularly those requiring quick turnaround times.

If your engineering department wants to start with sheet metal prototypes or final products, reach out to our team at Rapid Axis. We are a full-service machine shop that will act as your manufacturing partner. Simply put, we can help transform your engineering drawings into professional-grade production-quality parts.