Intro

The energy sector tends to prioritize quality, affordability, and turnaround times when it comes to manufacturing. Still, your energy company probably needs a dozen different parts manufactured, and you don’t have any time to waste. The good news? Rapid Axis can turn your manufacturing headaches into a simple and stress-free operation.

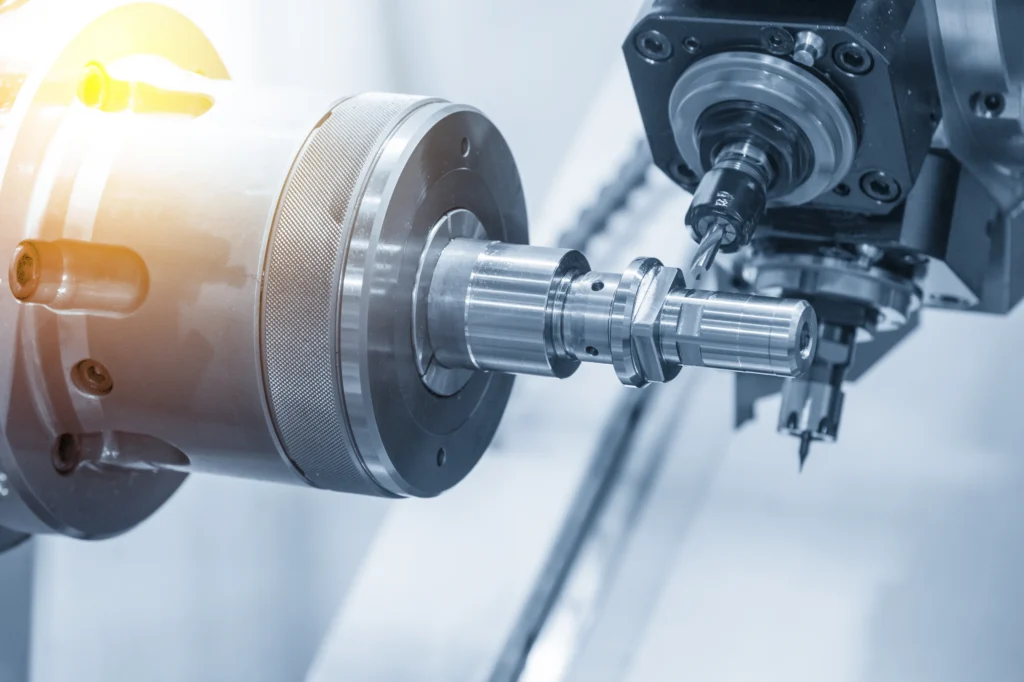

Our expert machinists at Rapid Axis are going to discuss how our CNC and sheet metal fabrication services can help save your energy company time and money, while creating high-quality, production-level parts.

Providing Custom CNC-Machined Parts

Our most popular service is our custom CNC-machined parts. Although we can help operations in any industry, we have a lot of interest from the energy sector. These CNC-machined parts can be as challenging and unique as you need them to be, and our experienced machinists will make it seem easy.

We can make CNC-machined parts out of common types of plastic and metal, and we’re here to help however you’d like. All you need to provide is manufacturing drawings and tolerances, and we’ll take it from there.

Creating Custom Power Generation Equipment

A lot of the energy sector revolves around alternative energy. To get the most out of your wind turbines and solar panels, you probably need high-quality sheet metal fabrication services, like the ones offered at Rapid Axis.

Wind Turbine Housings

The housings of your wind turbines will make sure no wind energy is lost through cracks or seams. These housings keep all of the internal parts intact, while providing a smooth airfoil-like surface to make sure you get the most power out of every bit of air.

These turbine housings have to be massive, and our sheet metal experts at Rapid Axis can handle the manufacturing for you.

Solar Panel Frames

Our custom sheet metal fabrication services will help you get unique solar panel frames. With different companies experimenting with unique sizes and orientations of solar panels, you can keep up with your own customized frames.

Using sheet metal to make your solar panel framework gives you a lot more design freedom when it comes to the overall dimensions and layout of your solar panels. With our help, you can convert even more sunlight into usable electricity.

Production-Quality Parts

We specialize in manufacturing anything from an initial prototype to a final product, and everything in between. With Rapid Axis, you can get production-quality parts quickly and affordably.

This can be a game-changer for energy companies that are trying to compete with the big guys. With more reliable, affordable, and expedited manufacturing through Rapid Axis, you can get your product to market sooner and grow your market share.

Sheet Metal Fabrication

Our custom sheet metal fabrication has helped a lot of companies within the energy sector. We can create unique, one-off parts using sheet metal at lower costs and faster turnarounds than traditional machining would cost you.

Our sheet metal experts can work with dozens of alloys and sub-types of metals to make sure you get the perfect final part. Wherever you might use sheet metal, you can improve the functionality, appearance, and affordability when you choose Rapid Axis.

Better Throughput and Turnaround Times

Quality is always the main focus of any manufacturing project that we take on. With that said, our team at Rapid Axis still offers some of the best throughputs and turnaround times that you’ll find on the market. We know that you don’t have time or money to waste, so we respect that idea with every project.

No matter what your newest project is, you can leverage our services to simplify the manufacturing of every part.

Create One-Off or Mass-Market Production Runs

Whether you need a single prototype or you want to make a mass-market push for your new product, our crew at Rapid Axis can help. We offer full-scale injection molding and CNC machining services to meet your production demands. At the same time, we have an array of 3D printers, sheet metal fabricators, and CNC machinery to help you get prototypes and custom parts.

We Offer Any Finishing Step You Might Need

Even when the manufacturing is done, our job isn’t finished. We offer a wide range of finishing steps to ensure the final quality is exactly what you’re looking for. We can anodize, powder-coat, paint, sand-blast, and add branding to any of your parts. This will help elevate the functionality and appearance of every product you make.

Conclusion

When you choose Rapid Axis, you’re signing up for a manufacturing partnership, not just a one-off fabricator. We are here to handle every part of your manufacturing needs. We’ve worked with energy companies for decades, and we know the intricate ins and outs of your industry.

Trust our team to handle your manufacturing, prototyping, mass-production, and finishing needs. Contact us today to get started and get a free quote.