Injection molding is the go-to manufacturing method for creating high-quality, consistent parts in large quantities. Among the various techniques, MUD insert injection molding offers a unique and efficient approach, especially for low- to medium-volume production or rapid prototyping. For mechanical engineers and designers exploring cost-effective and flexible injection molding solutions, understanding the benefits of MUD inserts can help you make informed decisions.

In this guide, we’ll explain everything you need to know about MUD — what it is, how it works, where you might use it, some major benefits, and picking the right manufacturer for your next MUD-based project.

What Is a MUD Insert Injection Mold?

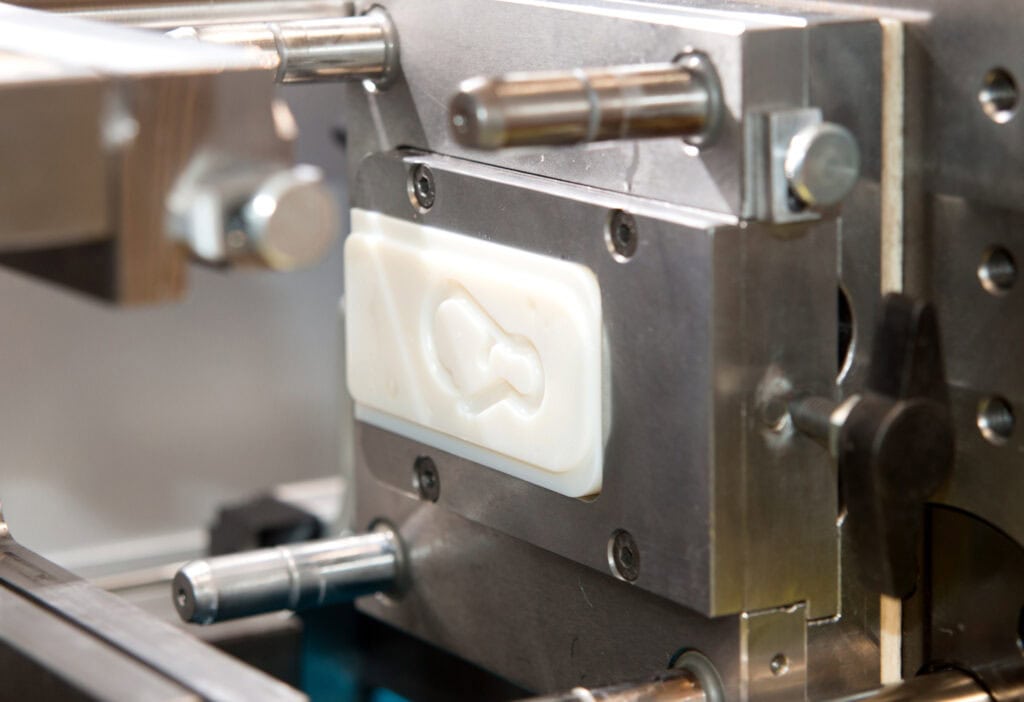

MUD stands for Master Unit Die, a system designed to simplify and streamline the injection molding process. Unlike traditional injection molds that require a complete mold set for each part, a MUD system uses a reusable base mold, also known as a master frame, into which interchangeable inserts are placed.

To put it simply, you have a complicated base that allows you to just swap out inserts in order to make different parts. You might use one insert for the shell of your assembly, another for one internal part, and another insert for the final part of your assembly.

Without a MUD insert, you would have three different entire tooling assemblies that equates to a much more expensive, complicated, and time-consuming project.

Each of the removable inserts in a MUD system is customized for a specific part, and it contains the cavity and core that define the part’s shape.

The master frame remains in the injection molding machine, while only the inserts are swapped out to produce different parts. This modular approach significantly reduces setup time, tooling costs, and material waste compared to creating a full mold for every part.

How Does MUD Insert Injection Molding Work?

The MUD process begins with the design and fabrication of the master frame and inserts. The master frame is a universal housing that holds the inserts in place during the molding process. The inserts, machined to the specifications of the desired part, contain the cavity (female portion) and core (male portion) where molten plastic will be injected.

When producing a part, the insert is securely mounted within the master frame. The frame is then loaded into the injection molding machine, where molten plastic is injected under high pressure.

Once the plastic cools and solidifies, the part is ejected, and the process can be repeated. When switching to a different part design, only the inserts are changed, leaving the master frame in place.

This ability to quickly change inserts makes MUD systems ideal for manufacturers who require flexibility and cost efficiency in their production runs.

It’s the equivalent of changing the bits in your hand drill instead of having a dozen different hand drills with permanent bits.

Industries and Applications for MUD Insert Injection Molding

MUD insert injection molding is widely used across various industries due to its adaptability and efficiency. In the automotive space, you can use MUD insert injection molding for prototyping and producing small components like clips, fasteners, and interior trims.

Medical companies lean on MUDs for creating precision components for devices, tools, and disposable products. Aerospace and electronics companies might use this type of molding for small, lightweight components that require high precision.

The modular nature of MUD molds allows manufacturers in these industries to adapt quickly to design changes and short production runs without the high cost of creating entirely new molds.

Benefits of MUD Inserts Over Traditional Molds

MUD systems offer several advantages over traditional injection molds, making them a preferred choice for certain applications.

- Cost Savings: Since the master frame is reusable, only the inserts need to be manufactured for each new part. This reduces tooling costs significantly.

- Faster Turnaround: Changing inserts is quicker and simpler than replacing an entire mold, reducing downtime and enabling rapid production cycles.

- Flexibility: MUD systems are ideal for short runs and prototyping, as they allow for easy adjustments to designs or material specifications.

- Reduced Material Waste: Inserts require less material to produce than full molds, making MUD systems more sustainable.

- Improved Efficiency: Operators can handle multiple parts within the same master frame, increasing production versatility without additional mold costs.

These benefits make MUD insert injection molding an attractive option for projects where cost, speed, and adaptability are critical.

The Importance of Choosing the Right Machine Shop

While MUD insert injection molding offers clear advantages, the success of the process hinges on selecting a reliable and experienced machine shop. Precision and attention to detail are paramount in designing both the master frame and the interchangeable inserts. A poorly machined insert can lead to defects, inconsistent parts, and increased maintenance costs.

At Rapid Axis, we specialize in crafting high-precision molds, including MUD insert systems, tailored to meet your specific requirements. Our expertise in CNC machining services ensures that every insert is manufactured to exact tolerances, while our advanced equipment and skilled team guarantee consistent quality and on-time delivery.

In addition to machining, we offer design for manufacturing (DFM) support, helping engineers optimize their designs for the MUD system. This collaboration not only ensures a smoother production process but also minimizes costs and reduces lead times.

Partner with Rapid Axis for MUD Insert Injection Molding

Whether you’re developing prototypes, managing short production runs, or exploring cost-effective solutions for small parts, MUD insert injection molding can deliver the results you need. Rapid Axis has the tools, expertise, and commitment to quality that ensure your project’s success. From designing custom inserts to providing expert guidance on material selection and process optimization, we’re here to help.

Conclusion

Contact Rapid Axis today to learn more about our injection molding capabilities and how we can support your next project. Let us show you how our injection molding and CNC milling services and can bring your designs to life with efficiency and reliability.