Intro

Threads are a big component when it comes to making a part for fabrication. Assemblies in every industry and application can benefit from removable pieces. Knowing what they are, how to design them, and how a CNC machinist will thread your piece are all important. This guide will help you design your next production part with threads. We’ll describe what threads are, how to specify a pitch, how the machinist will make them, and how to include them in your next design.

Internal or External Threads

First up, you need to understand where the threads are going. An “external thread” will look like a bolt in the end — with the threaded portion on the outside of the part.

An “internal thread” will work like a nut, allowing an externally threaded part to get screwed into the piece. In other words, the threads are on the inside of the part.

Understanding the Thread Pitch

Threads are typically made to a standard pitch. The pitch will tell you how many threads there are over an inch of the part. More threads indicate a steeper pitch.

It’s important to know that the internal and external threads need to have the same pitch or else the parts won’t screw together.

For imperial parts, you can choose between Unified National Coarse (UNC), Unified National Fine (UNF), and Unified National Extra Fine (UNEF). A short-cut is to call them coarse, fine, or extra fine.

If you look at a 1/4-inch bolt:

– UNC will have 20 threads per inch

– UNF will have 28 threads per inch

– UNEF will have 32 threads per inch

Therefore, a 1/4-20 is a 1/4-inch UNC bolt with 20 threads per inch.

For most applications, a UNC pitch should be used.

How Threads are CNC Machined

To make threads, there are a few different options. You can use a premade tool that you run through your part for internal threads and run your part through for external threads. This premade tool has its limitations and it’s not perfect.

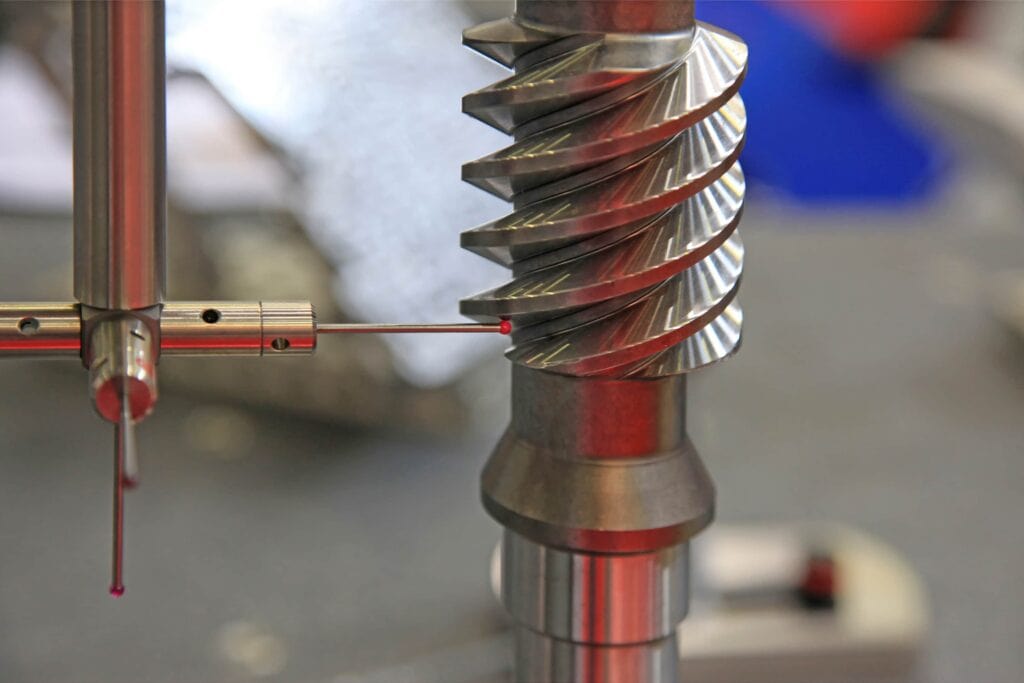

A more precise method is to use CNC machinery. The part can either be turned or a machine with a single-lip threading tool can be utilized.

Making Internal Threads on a CNC Machine

The machinist will first make a hole in your part that’s smaller than the final thread diameter. This will help with precision and accuracy.

Then, a single-lip threading tool is used. Imagine it as a single cross-section of a thread. As it cuts through the piece, you’re left with a part that has an internal thread.

This tool is rotated through your part at the correct pitch as the piece is translated along the depth of the thread.

In the end, you’ll have a mechanically precise internal thread.

Making External Threads on a CNC Machine

External threads often use a premade threading tool. These can be custom-made to meet different sizes, pitches, and lengths of external threads.

It can also be used in concentric or off-center threads. For more unique applications, live tooling can be used. It works in a similar way that internal threads are made, where the threads are carved out of the material.

Using CAD to Design Threads

If you are planning on having a part CNC machined, you can do a lot of the design work on CAD. For 3D modeled parts on SolidWorks, Inventor, or CREO, built-in thread-making tools will do all the work for you.

You can specify the location, size, pitch, and depth of the threads with a few clicks. Then, the machinist can take the 3D model and convert it into code that the CNC machine understands.

You just have to ensure you know the parameters for your threads prior to including them.

For 2D drawings, you’ll need to specify these parameters in paper space, so the machinist understands what to plug into their CNC machine.

In either case, cosmetic threads can be used. There’s no need to physically draw each of the threads for the sake of CNC machining — the machine will do that for you.

Use an Alternative to Cut Threads

In certain situations, you might not want to use threads. For example, threading into plastic or aluminum for high-use parts will quickly wear out the threads.

This is when designers will opt for alternatives like inserts. These are precision engineered parts with high-strength internal threads. The piece gets inserted where you want your threads to go. Instead of drilling and tapping plastic, a machinist will permanently insert these threads.

In the future, your assembly will screw together by using these threads and not vulnerable plastic threads.

Conclusion

As you can see, threading a part isn’t too difficult, as long as the part was designed correctly in the beginning. This guide should give you the confidence you need to include threads on your next assembly. If you have any more questions or want a professional shop to make your part, reach out to our team at Rapid Axis.