Threaded holes are essential in various mechanical assemblies, providing secure connections for screws and bolts. Properly machining these holes is critical to ensure reliable performance, reduce defects, and maintain structural integrity.

In this guide, we’ll talk about key guidelines and considerations for machining threaded holes, with insights on how to achieve optimal results using CNC machining services near you.

Machining Methods: Cutting vs. Forming

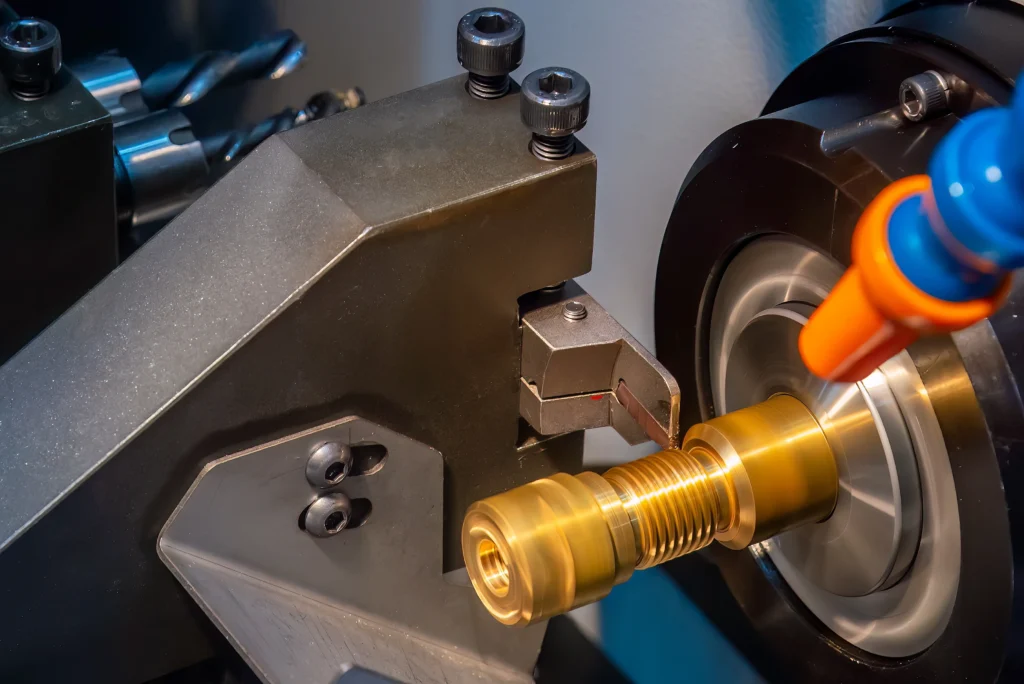

Threaded holes can be produced through cutting or forming methods. Cutting involves using taps or thread mills to cut into and remove material to create threads, making it ideal for harder materials and deeper holes.

Forming, on the other hand, displaces material to create threads, which works well with softer, ductile materials like aluminum and brass. When selecting the method, consider the material, hole size, and whether the hole is blind or through.

Cutting taps are recommended for hard materials since they allow for chip removal and lubrication. Forming taps are suitable for non-ferrous metals but can distort entry points due to the material displacement forces. Proper selection between these methods can improve thread quality and minimize tooling wear.

Types of Threaded Holes: Blind vs. Through

Machined holes come in two main types: blind and through. Blind holes do not pass completely through the part and need precise control over depth to prevent incomplete threading. We can use bottoming taps to maximize thread depth in blind holes.

Through holes, on the other hand, extend entirely through the part. For deeper through holes, consider adding a counterbore or stepping down the size of the hole to ensure our threading tools don’t snap off while trying to complete the thread. This should be used any time the threaded hole depth is 1.5 times longer than the thread’s diameter. For a 3/8-16 UNC bolt, that means any hole deeper than 9/16”.

Standardization and Tool Selection

Standardizing thread sizes to common specifications, such as those used in your region (e.g., UNC or Metric), can reduce machining time and costs. Off-the-shelf taps and tools are usually optimized for these standards, making it easier to maintain consistency in production. However, do not sacrifice design integrity just to fit a standard size if a custom solution is required.

In our experience, 99% of threaded holes can use standardized tap sizes. The only time you would venture away from off-the-shelf options is if you need a highly specific option, and specialized tooling can get really expensive to make and use.

Selecting the correct tool is equally important. For smaller threads, a machinist could even use a drill press to create the threaded holes. As the hole sizes get larger and deeper, we might need to use thread mills or special cutting tools to deal with the larger cutting forces.

Again, it’s better to use standard hole sizes and manageable depths. We can use a CNC milling machine or lathe to tackle most of the threaded holes your project needs. If you’re unsure about the design, give us a call and we’ll discuss how to make your threaded holes more manufacturable.

Positioning and Depth Management

Proper positioning is crucial when designing threaded holes. Ensure the hole is not too close to the part’s edge, since this can cause threading to break through the surface. A thread that’s “broken through” creates a sharp edge, compromises the part’s integrity, and looks very low-quality. It also causes mechanical issues since the bolt doesn’t have a full thread to thread into.

For blind holes, remember that our cutting tools have a tip to them, and the bits are not machined all the way to the end — plus, there will also be some chip accumulation within the hole. This is important to know, because giving us a drawing with a 1/4-20 UNC threaded hole that’s 1” deep, means that you will receive a part that does not have 1” of complete threads. After accounting for the tip size and lack of threaded portion on the bit, you might be left with closer to 3/4″ of usable thread.

To get the best results, design the holes to be deeper than you need them to be, and remember to include the hole tip, or else you’re asking for a machined pocket which is a more expensive and difficult process.

Tolerances should be tight but achievable, and overestimating depth ensures better thread engagement and structural security.

A threaded hole on an angled surface can require a more complicated machine, like a 5-axis milling machine. To keep things simple, consider designing a flat portion on the face that we can machine first before creating the threaded hole.

If this is not feasible, we can sequence the machining operations to minimize stress on the threading tools.

Best Practices and Partnering with CNC Machining Services

Following these guidelines can significantly improve the quality of threaded holes, leading to better performance in assembled parts. Our CNC machining services near you can provide valuable expertise and state-of-the-art equipment to achieve precise threading.

By working closely with a trusted partner like Rapid Axis, you ensure that your machining needs are met with the highest standards of accuracy and efficiency.

Conclusion

Threaded holes are more than just a minor feature; they are essential to the functionality and reliability of machined parts. By adhering to best practices in design, tool selection, and machining processes, you can ensure that your threaded components meet or exceed the necessary standards.

Contact Rapid Axis today to learn more about our CNC machining services and how we can assist with all your threaded hole requirements.