In the world of high-volume manufacturing, the efficiency and precision of the production process are paramount. One of the most effective methods for achieving this is through the use of an injection molding machine. Injection molds are crucial for producing large quantities of parts quickly, affordably, and consistently, making them a must-have for mass production.

In this article, we will explore the importance of injection molds in high-volume production and why Rapid Axis is the ideal partner for your injection molding needs.

The Importance of Injection Molds in High-Volume Manufacturing

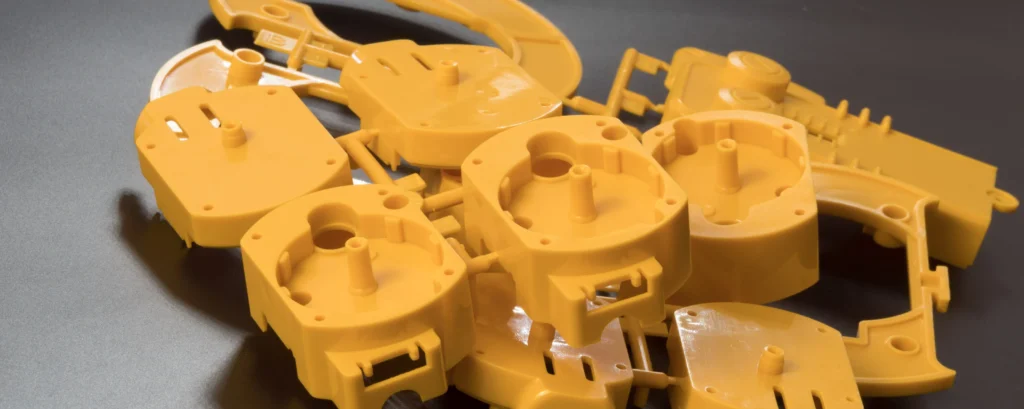

Injection molds are the backbone of high-volume manufacturing, enabling the production of thousands or even millions of identical parts with high precision and repeatability. Here’s why injection molds are so crucial for this type of production:

Efficiency and Speed

One of the primary advantages of using an injection molding machine is its ability to produce parts at an incredibly fast rate. Once the mold is created and set up, the injection molding process can produce parts in a matter of seconds. This high-speed production is essential for meeting the demands of high-volume manufacturing.

Consistency and Precision

Injection molds are designed to produce parts with exact specifications, ensuring that every piece is identical. This consistency is critical in industries where precision is vital, such as automotive, medical devices, and consumer electronics. The high precision of injection molding minimizes the need for additional processing or quality control, saving both time and money.

Material Versatility

Injection molding machines can work with a wide variety of materials, including various thermoplastics, thermosetting plastics, and elastomers. This versatility allows manufacturers to choose the best material for their specific application, ensuring optimal performance and durability of the final product.

Factors Contributing to the Longevity and Performance of Injection Molds

The longevity and performance of an injection mold are influenced by several factors. Understanding these factors can help you make informed decisions when selecting an injection molding partner:

Quality of Mold Materials

The materials used to construct the mold play a significant role in its durability and performance. High-quality steel or aluminum molds are more resistant to wear and tear, ensuring a longer lifespan and consistent performance over many production cycles.

Precision Engineering

The design and engineering of the mold are critical for achieving high precision and repeatability. Advanced CAD/CAM software and precision machining techniques ensure that the mold is accurately crafted to the exact specifications of the part being produced.

Regular Maintenance

Regular maintenance of the injection mold is essential for sustaining its performance and extending its lifespan. This includes cleaning, inspecting for wear and damage, and performing necessary repairs or adjustments. Proper maintenance prevents downtime and ensures the mold continues to produce high-quality parts.

Why Rapid Axis is the Right Company for High-Volume Injection Molding

At Rapid Axis, we understand the critical role that injection molds play in high-volume production. Our state-of-the-art injection molding machines and expert team make us the ideal partner for your manufacturing needs. Here’s why:

Advanced Machinery

Our injection molding machines are among the most efficient and productive in the industry. With advanced features and capabilities, they can handle complex molds and produce parts with exceptional speed and precision. This efficiency translates into shorter production cycles and higher output, allowing us to meet the demands of high-volume manufacturing.

Expertise and Experience

With years of experience in the industry, our team at Rapid Axis has the knowledge and skills to handle even the most challenging injection molding projects. We work closely with our clients to understand their specific needs and provide customized solutions that meet their requirements. Our expertise ensures that every project is executed flawlessly, from design and prototyping to full-scale production.

Commitment to Quality

Quality is at the heart of everything we do at Rapid Axis. We use only the highest quality materials and adhere to strict quality control measures throughout the manufacturing process. This commitment to quality ensures that every part we produce meets the highest standards of precision and performance.

Comprehensive Services

Not only can we run the injection molding machines, but we can also machine all of the tooling that’s used in the operation. In addition, we offer 3D printing, custom CNC machining, and finishing processes to ensure your full assemblies are ready to ship to customers.

This comprehensive suite of services allows us to provide end-to-end solutions for our clients, streamlining the production process and ensuring seamless integration of all manufacturing steps.

Conclusion

Injection molds are essential for high-volume production, offering unparalleled efficiency, precision, and consistency. At Rapid Axis, our advanced injection molding machines and expert team make us the perfect partner for your manufacturing needs. Whether you are producing automotive parts, medical devices, or consumer electronics, we have the tools and expertise to deliver high-quality parts on time and within budget.

Choose Rapid Axis for your next high-volume injection molding project and experience the difference that our commitment to excellence can make. Contact us today for a free quote and let us help you bring your products to life with the precision and efficiency of our injection molding services.