Intro

Picking the right CNC milling machine is the first step to getting the best possible parts. A good milling machine will allow a machine shop to make parts quicker, more affordably, and more repeatably. Within the world of CNC milling machines, many machinists have to choose between a 5-axis or a 3+2 axis machine.

In this guide, we’ll explain each of these options. We’ll provide you with detailed advantages of both, so you know which machine to look for next time you’re evaluating a potential manufacturing partner.

What Is 3+2 Axis Machining?

Let’s start with 3+2 CNC machines. Modern milling machines come with 3 axes that allow the part to move in the X, Y, and Z axis — left and right, forward and backward, and up and down.

The additional 2 axes come as a rotation of the cutting tool. The added A axis rotates around the X axis, and the B axis rotates around the Y axis.

This is a bit confusing, but it’s a simple way to add extra versatility to your machine. With a 3+2 axis machine, you can cut more complex shapes and handle non-orthogonal features.

However, these added 2 axes are static, or stationary. The machinist would set the angle of the cutting head before they start machining the part, and the cutting head will stay at that angle the entire time.

As a simple example, consider a machinist cutting a chamfer on a part. They might use a 3+2 axis machine to set the cutting head to 30°, keep it in this position, then run it past the part’s edge that needs to be chamfered.

What Is Simultaneous 5-Axis Machining?

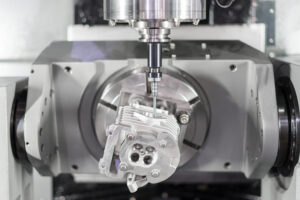

Simultaneous 5-axis machining is the latest and greatest version of CNC machining. Just like 3+2 machining, 5-axis machining allows the tool (or part) to rotate in all 5 axes.

The big difference is that simultaneous 5-axis machines can move dynamically, as opposed to the static nature of 3+2 machining. What does that mean? Well, a 5-axis machine’s cutting head can continuously move and rotate through cuts.

If you watch a 5-axis machine run, you’ll see the cutting tool dance across a part and hit very specific angles for different features.

A 5-axis machine can be used to cut a doorknob out of a single block of material, instead of turning it on a lathe.

The difference between a 3+2 and a 5-axis machine is whether or not the tool can change its angle during a cut (5-axis), or if it needs to be set up before cutting (3+2 axis).

Advantages of 5-Axis Machining

When it comes to 5-axis machining, all of the advantages are due to the dynamic fourth and fifth axes. Here are some common advantages of using this machine:

Better Accuracy

As a whole, 5-axis CNC milling machines are more accurate and provide better precision on your parts. Since the cutting tool can move as cuts are made, you’re removing human error elements and potential misalignments. Instead, the machine’s tooling ensures a perfect cut, every time.

Ability to Make More Intricate Parts

Since the cutting head can move dynamically along two more axes, the machinist can make much more intricate parts on a 5-axis machine. This is the best option to make complicated engineering parts.

There are sculpturists who make works of art with 5-axis CNC milling machines, so this machine can certainly stand up to whatever design you throw its way.

Faster Operation

With a simultaneous 5-axis milling machine, a machinist can cut 5 faces with a single setup. The machine only needs to grip the bottom face, while it performs a vast majority of the cutting and drilling operations.

In addition, the machine will dynamically go through and set itself up for every cut it needs to make in real-time. With much less operator interference, a 5-axis machine can run with little supervision. This directly translates to faster operations, faster cycle times, and expedited delivery on all of your parts.

Conclusion

As you just learned, there are a lot of benefits to using a 5-axis CNC milling machine. It’s a faster option that allows you to design more complicated parts and have them machined accurately. If you want a high-quality manufacturing partner that has in-house 5-axis machines, consider Rapid Axis. Our full-service machine shop can handle most of your manufacturing needs. Get a free quote today.