Overview:

AeroCase, a leading innovator in phone protection solutions, takes pride in its commitment to precision, innovation, and quality. With core values deeply rooted in delivering superior products to its customers, AeroCase sought a partner who could match their dedication to excellence. Rapid Axis, a renowned machining expert, emerged as the ideal collaborator, showcasing a similar commitment to quality and precision.

Challenges:

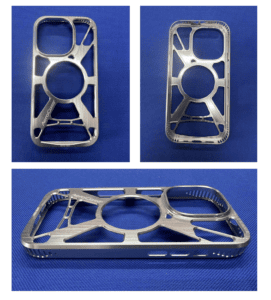

- AeroCase faced the challenge of creating a remarkably thin (.030”) 5-axis component with intricate undercuts.

- The complexity of this component made many machine shops hesitant to undertake the project due to the risk of damage during machining and inspection.

Objectives:

This component was a critical part of AeroCase’s innovative venture – the first fully metallic exoskeleton phone protection system in the market.

How Rapid Axis Stepped In:

Rapid Axis not only accepted the challenge but exceeded expectations. We delivered flawlessly machined hardware that met the stringent requirements promptly. The willingness to tackle the project’s complexity showcased exceptional skill and unwavering commitment. AeroCase found in Rapid Axis a partner capable of translating vision into reality, ultimately contributing to the success of their groundbreaking product.

The Results:

The successful completion of the intricate component highlighted precision and attention to detail. AeroCase received precisely machined hardware that met the high standards set for the project. Rapid Axis’s expertise in handling the delicate nature of the part, which posed challenges for other shops, demonstrated their professionalism and commitment to quality. This collaboration led to a product that met AeroCase’s requirements and explored new possibilities within the given parameters.

- Drop Test Compliance: AeroCase conforms to the U.S. Department of Defense Environmental Test Method Standard, MIL-STD-810G 516.6. This stringent testing involves subjecting the device to 24 drops from a height of 4 feet, impacting on all edges, corners, and faces, ensuring unparalleled durability and robustness.

- Wireless Charging Compatibility: Nominal wireless charging performance, especially when used with Apple Magsafe chargers.

- Innovative Structural Design: AeroCase’s proprietary design strategically reduces stiffness in impact areas, enhancing both energy absorption and spectral attenuation during impacts.

- Seamless Connectivity: This design preserves wireless communications seamlessly, maintaining uninterrupted connectivity while providing comprehensive device protection.

- Elegance and Remarkable Finishes: The functional design is complemented by exquisite finishes, creating a product that seamlessly merges aesthetics with technical superiority.

Perception and Recommendation:

Since partnering with Rapid Axis, AeroCase’s perception of the company transformed significantly. Rapid Axis’s professionalism, punctuality, and precise machining capabilities left an indelible impression. Rapid Axis consistently met or surpassed quoted lead times, delivering high-quality, customer-facing products without compromise. AeroCase now confidently recommends Rapid Axis to colleagues, friends, and clients, emphasizing reliability and superior quality of workmanship.

“Rapid Axis’ professional communication, on-time delivery, and accurate machining is impressive.”

Nathan Lipshutz, President of AeroCase LLC

Conclusion:

Rapid Axis’s dedication to overcoming challenges and delivering precise, timely solutions has made them a trusted partner for AeroCase. This collaboration has strengthened both companies’ commitment to excellence, establishing a foundation for future projects. Rapid Axis’s reliable service has consistently met AeroCase’s needs, fostering a partnership grounded in trust, expertise, and mutual values.