Intro

3D printing is a great way to get quick prototypes without paying too much. As you’re shopping for the right FDM printing service, you might have stumbled across companies also offering resin or SLA 3D printing. The difference between the two can be confusing, so how are you supposed to choose between resin vs FDM printing?

We’re here to help. Our 3D printing experts at Rapid Axis will answer all of your questions. In this quick guide, we’ll describe the differences between resin vs FDM printing. Ultimately, we’ll help you to understand which option is right for you.

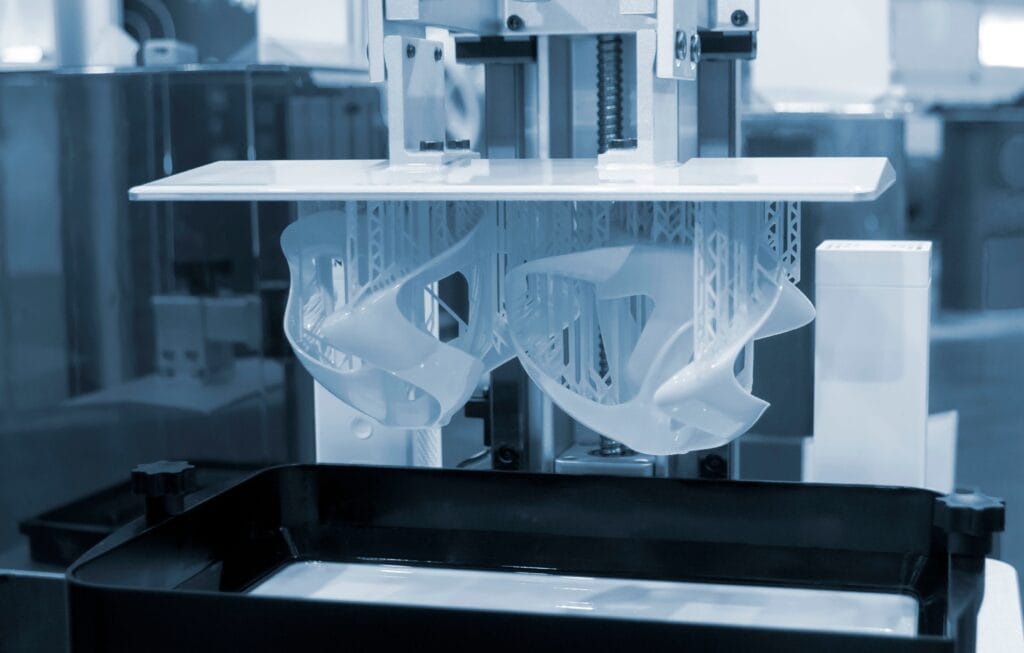

What Is Resin (SLA) Printing?

Stereolithography (SLA) is the technical term for resin 3D printing, and it’s a great option for professional applications. It uses a laser to cure UV-sensitive liquid resin, one layer at a time. With SLA printing, the result looks more professional and polished.

What Is FDM Printing?

Fused deposition modeling (FDM) printing is the most popular 3D printing option on the market at a consumer level. An FDM printer will lay down beads of molten plastic, and build from the bottom of a part to its top, one layer at a time. The molten plastic cools, hardens, and fuses together (hence the name!).

With FDM printing, the simplicity of material melting as it passes through a hot extruder opens up the availability of materials — generally speaking, most plastics that are solid at room temperature and melt under 300°C can be used in an FDM printer.

Differences Between Resin (SLA) and FDM Printing

Before you can pick between resin and FDM printing, you should understand the differences between the two. Consider these categories to help you make your decision.

Final Resolution

The final resolution of an SLA-printed part is much better than an FDM-printed part. This is largely due to the high-precision laser used in a resin printer, carefully activating resin in a small line.

Alternatively, FDM printers use a larger, bulkier extrusion method that leads to more variation in line thickness and total dimensions — not to mention, FDM printers lay material down as a cylindrical line, making it much harder to achieve flat, smooth faces.

Material Options

When it comes to material options, it’s hard to find a better option than FDM printing. When you work with an FDM printing service, the material choice and color are two of the bigger decisions you’ll make. A standard FDM printer can print with hundreds of different material options.

With SLA printers, you’re incredibly limited to a dozen different resin types.

Ease of Use (or Availability)

Using an FDM printer is typically as simple as loading a spool of filament, loading the sliced CAD model, and hitting “go”. With resin printers, there is more setup and finesse that goes into the system.

As a result, there is an availability issue when it comes to outsourcing your resin vs FDM printing work. You’ll find more FDM-capable shops than you will SLA-capable shops.

Of course, we handle both of these options and many more 3D printing styles at Rapid Axis.

Upfront and Continued Costs

If you want to run your own 3D printing operation, you’re better off with FDM printing. The printers themselves are less expensive, and material costs are much lower in continuity. Plus, there’s very little maintenance.

With SLA printers, the upfront cost is higher, maintenance costs are higher, and material costs can get more expensive as well.

If you’re outsourcing the work, expect to pay a little more for SLA-printed parts.

Overall Build Volume

The average FDM printer tends to be larger than the average SLA printer. The big limiting factor is the additional height needed for the laser assembly that the FDM printer doesn’t need to worry about.

As a result, you can make taller parts with FDM printers, allowing you to tackle larger projects.

Keep in mind, you can always design parts that bolt, adhere, or snap together if you want to make multiple smaller parts.

Surface Finish and Quality

The default quality and surface finish you can achieve with an SLA printer are almost impossible with an FDM printer. For more professional-looking parts, then consider SLA printing.

Throughput and Printing Speeds

Another benefit of SLA printing is that it offers higher throughputs as a result of its faster printing speeds. The laser moves faster, indexes faster, and hardens the resin faster than an FDM printer does.

This means that SLA printing is a good option in applications where you need multiple units made in very little time.

Typical Applications for Resin (SLA) and FDM Printing

The applications of resin vs FDM printing might also help you make up your mind. Generally, you might use FDM printers for:

- Low-cost consumer goods

- Quick prototypes

- Easy, smaller parts

- Proof of concepts

Resin (SLA) printers are a good option for:

- High-precision, accurate parts

- Production-level parts

- Functional prototypes

- Medium-volume production

Resin vs FDM Printing: Which Is Right for You?

So, which option is better between resin vs FDM printing? It really has to do with your application. If you want a quick, inexpensive part made with no stress, then choose FDM printing. The final resolution won’t be great, but it’s the better choice for quick proof-of-concept projects, or if you need a physical part for fitments or demonstrations.

For more production-quality units, SLA printers are much better. Resin is a stronger material, the quality is higher, and you’ll have a more functional unit.

Conclusion

Regardless of what type of 3D printing you’re looking for, you can trust Rapid Axis. With our in-house 3D printers, we offer FDM, SLA, MJF, Polyjet, DMLS, and SLS 3D printing.

Talk to our 3D printing experts to better understand the difference between these options so you can hand-pick the perfect option for your next project. Get a free quote today.