Intro

A well-made prototype can save you a lot of time and money in the future. If you perfect the design before going to full-scale production, you’ll see the best results. For most people, that means choosing the right option for making a prototype.

In this guide, we’ll be talking about metal prototypes. More specifically, we’ll outline 4 of the best options to make metal prototypes.

What Is a Prototype?

A prototype is typically the first phase of making a production product. If you want to make a new line of medical devices, it starts with a prototype.

During the prototyping phase, you’ll be able to do fitments, check for clearances, do failure testing, and showcase your product to interested stakeholders. A well-made prototype will tell you everything you need to know in order to make your production model.

Usually, people will change their part’s design after making a prototype and testing it out. There might be slight problems that you didn’t realize while designing, but the physical prototype will show you.

Advantages of Metal Prototypes

For prototyping, a lot of people will use plastic and 3D print the part. However, plastic is very weak and doesn’t work in high-stress situations. Plus, why would you make a plastic prototype for a part that will eventually be metal?

This is where metal prototypes come in. You can get better feedback when the prototype is made out of the same material that your final product will be made out of — in this case, metal.

Metal prototypes are also very strong, which helps with physical testing.

Best Options for Making Metal Prototypes

If you want a great metal prototype, you have a few options to pick from. Our expert machinists typically suggest four options for making a metal prototype. In this section, we’ll give you the facts you need to pick the right manufacturing method for your prototype.

Sheet Metal Prototypes

Sheet metal is a thin piece of metal that you can use to make prototypes. It’s very easy to bend and drill holes in, and you can even bend it into a box with flanges and special cuts. This is the best option for any type of shroud or container you want to make.

For instance, you could make a custom sheet metal prototype to cover electronic components or make a housing to protect your delicate assembly (think of a speaker housing or computer tower).

Sheet metal is not as strong as other metal options, and it takes specialized skills to work with. You can either laser cut, CNC mill, or waterjet cut sheet metal into its shape before bending it.

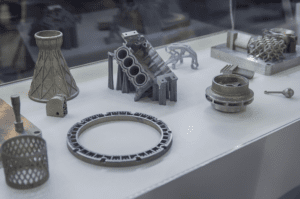

3D-Printed Metal Prototypes

We mentioned that you can 3D print plastic prototypes, but an advanced machine shop can also 3D print metal parts. At Rapid Axis, we use a DMLS 3D printer that allows us to 3D print parts making pure aluminum, stainless steel, or titanium. Once we print and cure the part, it will be virtually indistinguishable from a solid machined block of metal.

3D printing with metal gives you the most design freedom, allowing you to create customized parts. The 3D printing process is relatively quick, and the final parts are very strong. We can also apply post-processing steps to paint, coat, or plate the part.

CNC Machined Metal Prototypes

The traditional way to make metal prototypes is through CNC machining. We would utilize a combination of a milling machine and lathe to create your prototype.

This option takes a little longer than 3D printing or using sheet metal, but you’re left with a strong part. Also, CNC machines can handle a wide range of material options and thicknesses (including titanium, stainless steel, aluminum, and more), so you have plenty of freedom when it comes to designing.

We can apply finishing steps to a CNC machined part, changing the color and surface characteristics.

CNC machining might be more expensive, depending on your specific product. It’s still a great option for low-batch production runs, and you can use the same CNC machining operation to make medium-scale production runs.

Metal Die Casting for Prototypes

Metal die casting is less common for prototypes, but it’s just as viable. This option entails making a negative version of your part in a strong core, filling it with molten metal, letting it cool and harden, then pushing out the hardened part. The result is a solid version of your prototype.

The reason why metal die casting is less common for prototypes is because you typically need to make a few hundred parts before you can justify the high upfront cost. There are ways for us to make low-quantity dies, but they come with an expensive upfront cost for tooling.

If your prototype’s design doesn’t change at all, we can use the same die to continue making die-cast versions of your part. The turnaround time is largely contingent on the upfront tooling. Once that tooling is done, you can expect very quick turnarounds on your parts.

Conclusion

As you just learned, choosing between metal die casting, CNC machining, 3D printing, and sheet metal fabrication can help you unlock the best prototype. Of course, you need to pick the right machine shop to help you out. At Rapid Axis, we can handle all four of these methods and much more. Get a free quote today to get started.