Aluminum: Advantages, Applications, and Material FAQs

Aluminum is one of the most commonly used metals across the globe. In our shop’s history, it’s hard to think of a single week when we didn’t make an aluminum part for someone. Industries from aerospace to consumer products and medical device companies use aluminum for a variety of different applications.

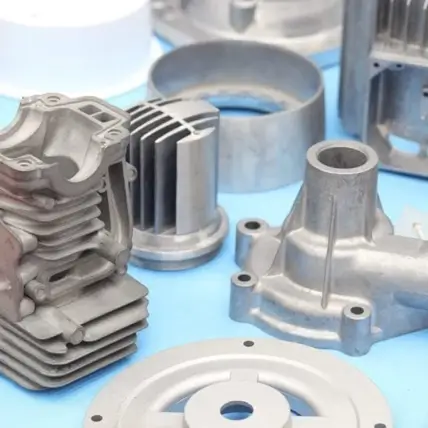

Aluminum is widely used in many industries due to its well-rounded mechanical properties. Multiple aluminum alloys are available through the following manufacturing services:

What Is Aluminum?

Aluminum is a silver-colored, non-ferrous metal that is versatile, easy to source since it is a very abundant metal, and cost-effective. It also has a low density and high strength, giving it one of the better strength-to-weight ratios compared to other metals. This makes aluminum a great choice in industries where mass reduction is important.

It can be purchased in a variety of different thicknesses, from very thin sheet metal (as thin as aluminum foil) to very thick stock plates.

Using pure aluminum is pretty rare. In most cases, you’ll use an aluminum alloy, which just means the metal is a combination of pure aluminum, magnesium, silicon, copper, zinc, and other materials in various quantities. The combination of these materials creates specific mechanical and thermal properties, with each alloy lending itself better to one application or another.

As a material, aluminum strikes a nice balance between durability, corrosion resistance, cost-effectiveness, strength, and machinability. For many companies and mechanical designers, it’s the “go-to” metal when they create new parts.

Applications

There are too many applications for aluminum to list, since it’s one of the most versatile and readily-available metals, you’ll see it used across industries.

Aluminum can be used in structural components due to its high strength-to-weight ratio. It is commonly used in electrical enclosures and housings since it can be bent, welded, and machined easily. It’s also a great choice for a variety of consumer products since it’s affordable, easy to work with, versatile, and offers a range of aesthetically-pleasing finishes.

More About Aluminum Alloys

There are a lot of different aluminum alloys to choose from:

1000 series

This is pure aluminum, which is corrosion-resistant and great for food processing applications, but much weaker than other aluminum alloys.

2000 series

Adding copper allows 2000-series aluminum to be stronger but less corrosion resistant. This is usually used in aerospace applications.

3000 series

This series adds manganese, which helps with formability, so this option is better for sheet metal applications like roofing and siding.

4000 series

With the addition of silicon, 4000-series aluminum has great wear resistance, so it can be used in automotive engines and moving parts.

5000 series

With the addition of magnesium (not manganese, like 3000-series aluminum), 5000-series aluminum has really good corrosion resistance, so you can use it in saltwater marine projects.

6000 series

Perhaps the most common, 6000-series aluminum has magnesium and silicon, which makes this alloy strong, versatile, corrosion-resistant, easily machinable, and durable. You can find 6000-series aluminum used across industries, with applications in construction, industrial, consumer, and medical projects.

7000 series

This adds zinc, which adds a lot of strength and is ideal for high-performance aerospace projects.

Strengths and Limitations of Aluminum

Aluminum has a lot of unique strengths and limitations, compared to other metals.

Strengths:

- Lightweight. At one-third the weight of steel, aluminum is a more lightweight metal.

- Corrosion-resistant. It naturally forms a protective oxide layer that prevents rust.

- Manufacturability. Aluminum is easy to cut, mill, shape, form, drill, and cut on a lathe.

- Electrical and thermal conductivity. Aluminum conducts heat and electricity well, so it can be used in electronics and heat exchangers.

Limitations:

- Not as strong as steel. Though aluminum is lighter than steel, it’s also not as strong. For very high-stress applications, steel might be a better option.

- Poor fatigue resistance. Aluminum is also less resistant to cyclic stresses, so it will fail before a steel part.

- Worse thermal expansion. Finally, aluminum expands more than other metals under heat, so you need to be careful using aluminum in high-temperature environments, especially if the temperature fluctuates or the aluminum is touching dissimilar metals.

Metals Similar to Aluminum

Aluminum has a lot of great features, but it might not be the right material for your project. If that’s the case, here are some similar metals that might be a better choice:

Stainless Steel

Stainless steel is the closest metal to aluminum. Stainless steel is stronger, tougher, more durable, and is also corrosion-resistant. Of course, steel is heavier and can be more expensive.

Titanium

If you want to take your strength-to-weight ratio one step further, titanium is the right choice. It is lighter and stronger, but also much more expensive and more difficult to machine than aluminum. For that reason, you should only choose titanium for specialty applications, and stick to aluminum for general-use scenarios.

Zinc

For die-casting projects, zinc is another metal that might work. It is more cost-effective and offers great precision within a mold, so you can use it if your die-cast part isn’t going to see heavy loads.

Mild Steel

Finally, you might consider mild steel. This metal isn’t corrosion-resistant like stainless steel, so you’ll need to use powder coating or another finishing step to help prevent rust and enhance durability. Still, mild steel is more affordable than stainless steel and offers many of the same mechanical properties, including its great strength and durability.

FAQs

Aluminum weighs about one-third as much as steel, making it the clear winner for weight-sensitive applications. However, steel is significantly stronger than aluminum. This means that while aluminum offers an excellent strength-to-weight ratio, steel is the better choice for applications requiring maximum strength where weight isn’t a primary concern. For many projects, aluminum’s combination of reasonable strength and light weight makes it ideal, but for very high-stress applications, you’ll want to stick with steel.

Yes, aluminum is naturally corrosion-resistant. It forms a protective oxide layer on its surface that acts as a barrier against rust and corrosion. This makes aluminum a great choice for outdoor applications and environments where moisture is present. Different aluminum alloys offer varying levels of corrosion resistance—for example, 5000-series aluminum with added magnesium provides excellent corrosion resistance even in saltwater marine environments. While not as corrosion-resistant as stainless steel in extreme conditions, aluminum’s natural protection is sufficient for most applications.

Aluminum has limitations in high-temperature environments. It has a higher thermal expansion rate than other metals, meaning it expands more when heated. This can cause issues in applications with temperature fluctuations or where aluminum interfaces with dissimilar metals. Additionally, aluminum’s strength decreases at elevated temperatures more rapidly than other metals, such as steel. While aluminum conducts heat well (making it useful for heat exchangers), you need to consider thermal expansion and strength requirements when using aluminum in high-temperature applications.

Absolutely. Aluminum’s high strength-to-weight ratio makes it an excellent choice for many structural applications, especially where weight reduction is important. You’ll find aluminum used in everything from building frameworks to aerospace structures. The 6000-series aluminum alloys are particularly popular for structural components because they combine good strength, corrosion resistance, and machinability. However, for structures under extreme loads or requiring maximum durability, steel might be more appropriate due to its superior strength and fatigue resistance.

Yes, aluminum actually performs quite well in cryogenic applications. Unlike some metals that become brittle at extremely low temperatures, aluminum maintains its ductility and actually increases in strength as temperatures drop. This makes certain aluminum alloys suitable for applications like liquefied natural gas (LNG) storage, aerospace components, and scientific equipment that operates at very low temperatures. The 5000 and 6000-series aluminum alloys are particularly well-suited for cryogenic use due to their combination of low-temperature toughness and corrosion resistance.

Yes, aluminum is considered one of the more sustainable metal options. It’s highly recyclable—in fact, aluminum can be recycled indefinitely without losing its properties, and recycling aluminum uses only about 5% of the energy required to produce new aluminum from raw materials. This makes recycled aluminum extremely cost-effective and environmentally friendly. Additionally, aluminum’s lightweight nature contributes to fuel efficiency in transportation applications, and its durability and corrosion resistance mean aluminum parts often have long service lives, reducing replacement needs.