4140 Alloy Steel: Advantages, Applications, and Material FAQs

4140 alloy steel is a great option across industries. It offers impressive strength that makes it a go-to alloy for a lot of manufacturing projects. Anything from load-bearing chains to crankshafts and gears utilize 4140 to make sure the components will last a long time before failing.

At Rapid Axis, we produce countless 4140 parts every year for companies across a wide range of industries and applications.

What Is 4140 Alloy Steel?

4140 alloy steel is a versatile material choice that has exceptional strength, wear resistance, and fatigue performance thanks to the combination of chromium, molybdenum, carbon, manganese, and silicon. This low-alloy steel has great fatigue strength and torsional strength, making it a great choice for parts that rotate and undergo a lot of stress.

As a material, it can be found in a number of different forms. Commonly, you’ll find raw 4140 steel in round bars, shaft stock, plates or blocks, flat sheets, tubes, and some common forged shapes.

Across the world, there are some different names for 4140 steel. In Europe, it’s called 42CrMo4, China calls it 42CrMo, and Japan uses the name SCM440.

Applications

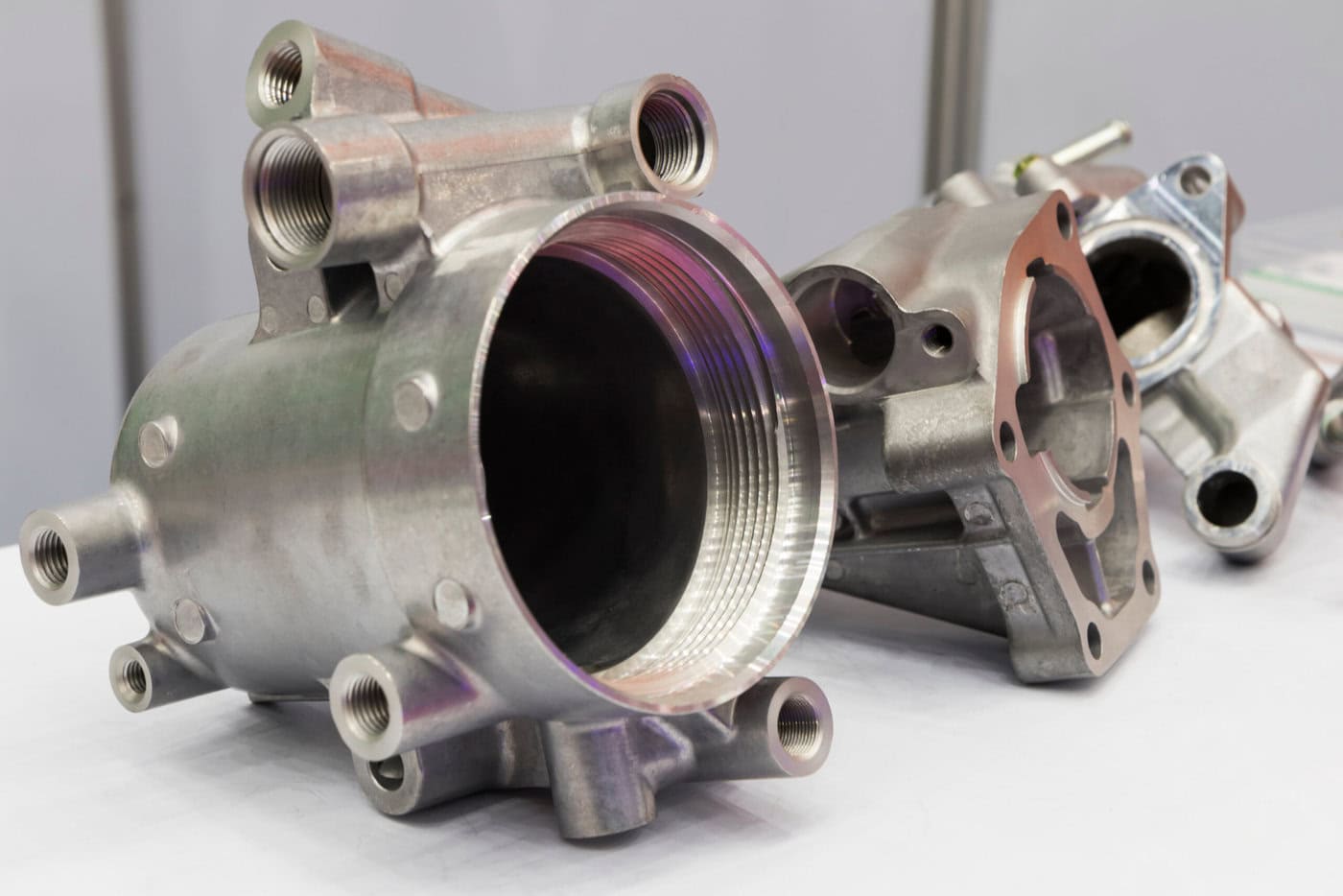

Many different industries use 4140 alloy steel, and you can find dozens of different applications where this alloy is the best choice. At Rapid Axis, we’ve seen 4140 used in a number of different part types:

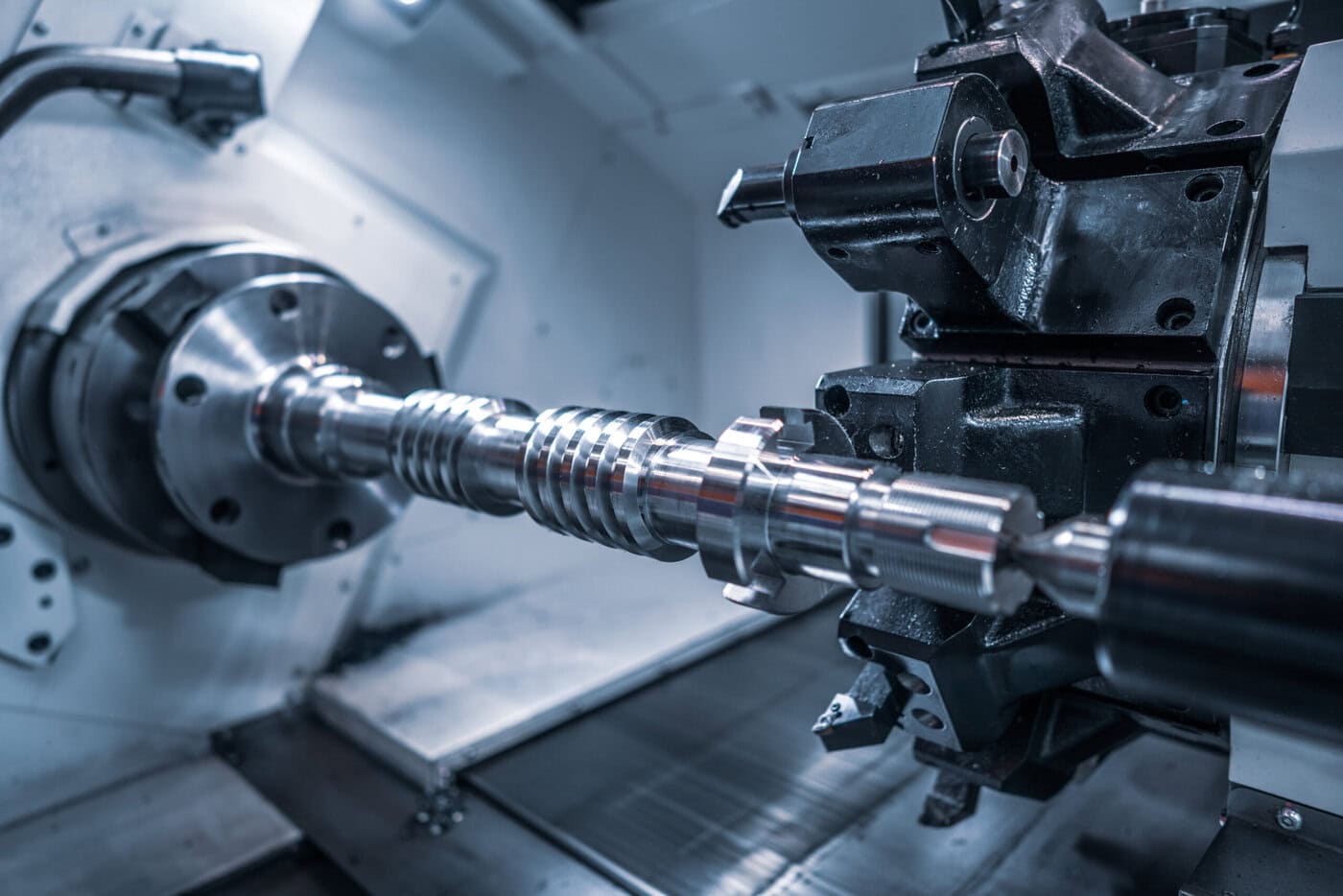

Shafts and spindles

The most common examples that come to mind are shafts and spindles made out of 4140 alloy steel, since it boasts such great torsional strength.

Gears, splines, and sprockets

Since the material can be hardened to be even longer lasting, you can use 4140 steel to create friction gears that last longer than other steel gears.

Structural brackets

With high tensile strength and fatigue resistance, 4140 steel is commonly used in structural brackets to avoid cyclic failure.

High-tensile strength fasteners

A more niche example for 4140 steel is bolts, studs, and threaded rods that need high tensile strength for dynamic loads or specialty heat treatability to achieve grade-specific specs.

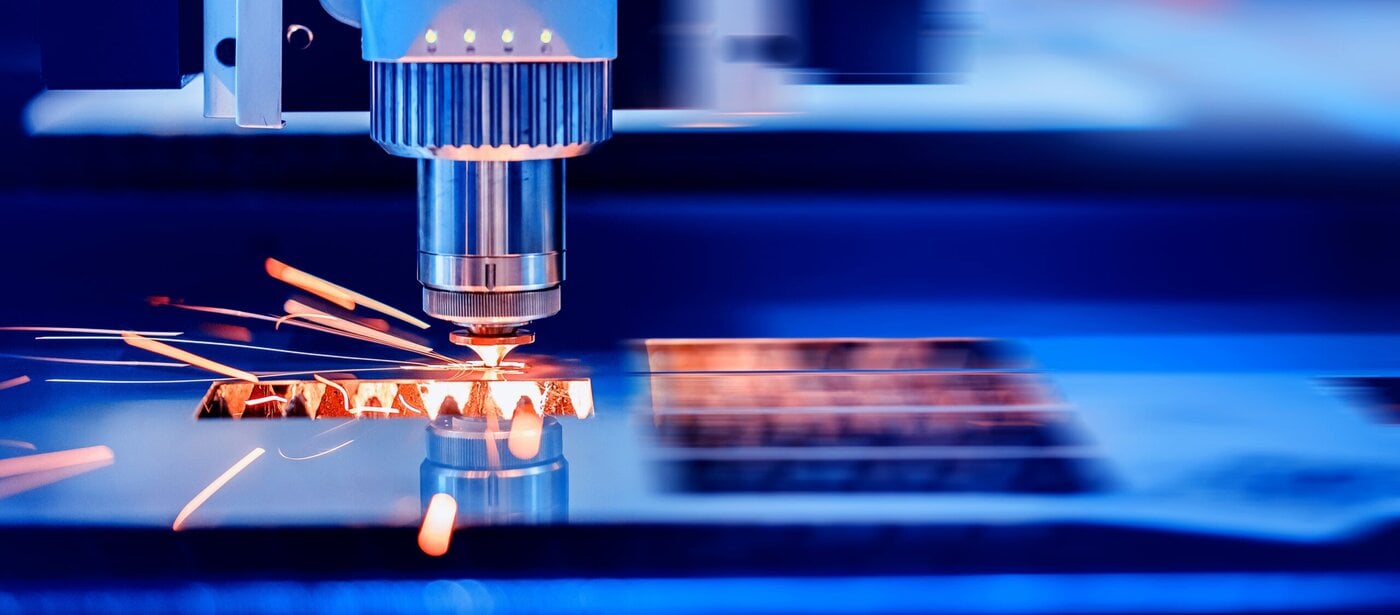

Tooling and dies

Another common application for 4140 steel is tooling and dies, since this alloy can resist deformation under load. This will help you achieve tighter tolerances and long-lasting dimensional stability.

Strengths and Limitations of 4140 Alloy Steel

In general, 4140 steel is a great alloy to pick for a wide range of applications. This alloy comes with a lot of strengths, and a few limitations to consider:

Strengths:

- High strength. One of the most impressive aspects of 4140 alloy steel is its high strength, making it the clear choice in load-bearing applications.

- Great fatigue resistance. The same part can undergo long-term loading and last longer than a similar part made out of another steel alloy.

- Easy to machine. 4140 steel is surprisingly easy to machine, especially compared to other specialty alloys. It doesn’t require specialty tooling, making it a more universal alloy within machine shops.

- Tough and versatile. This alloy can be used in different applications and industries since it is such a versatile material, offering better toughness than other steel alloys.

Limitations:

- Requires coating to be corrosion-resistant. Keep in mind, 4140 steel is not corrosion-resistant, so you’ll need to add a powder coating or plating to prevent rust.

- Sensitive to heat treatment. If a machine shop does not use the right hardening and tempering process, your parts can be brittle. For that reason, make sure you use a shop like Rapid Axis to get the most out of your 4140 steel parts.

- Not a sanitary steel. Unfortunately, this alloy does not have the biocompatibility or sanitary requirements to be used in medical applications or some cleanrooms.

Metals Similar to 4140 Alloy Steel

As you probably know, there are a lot of different steel alloys to choose from. In fact, there are a few options that are similar to 4140 alloy steel that are worth mentioning.

4130 steel

has less carbon, which makes it more weldable but slightly lower tensile and ultimate strength values. In other words, it is easier to weld but can handle smaller forces.

4340 steel

offers better toughness and fatigue resistance, and we’ll usually use 4340 in aerospace applications.

1045 steel

or plain carbon steel, is a less expensive alloy. However, it has less strength and can’t be hardened as well as 4140.

A2 tool steel

is an air-hardened tool steel that is designed specifically for tooling and dies, since it has better wear resistance for long-term use. However, it can be expensive and difficult to work with.