1045 Carbon Steel: Strengths, Applications, and Material FAQs

1045 steel is a very popular option for parts that need to be strong without the added cost or complexity associated with chromium- or molybdenum-based alloy steels. At Rapid Axis, we offer CNC machining services, sheet metal fabrication, and custom metal fabrication to make sure you receive the exact 1045 steel parts you’re looking for.

For many companies, 1045 carbon steel hits the sweet spot between cost, strength, machinability, and versatility. It is a medium-carbon steel that has better mechanical properties than lower grades.

What Is 1045 Carbon Steel?

1045 carbon steel is a plain carbon steel that falls into the 10xx naming convention of steel alloys. The 45 at the end indicates a carbon content of 0.45%, which gives added strength, hardness, and wear resistance over low-carbon steels like 1018.

This alloy also has small amounts of manganese, sulfur, and phosphorus that are all under 1% combined. As a simpler alloy, 1045 carbon steel can be very affordable and easy to machine and form.

European markets call 1045 carbon steel “C45E” or “Ck45”, Japanese markets use the name S45C, and the name “45 steel” is used in China.

As a versatile material, you can find 1045 carbon steel sold in a number of different forms. It is commonly sold as cold-drawn or hot-rolled bars, plates, blocks, forged billets, blanks for shafts or gears, flat sheet metal, or annealed stock material.

Applications

There are a few common applications of 1045 carbon steel that you might consider:

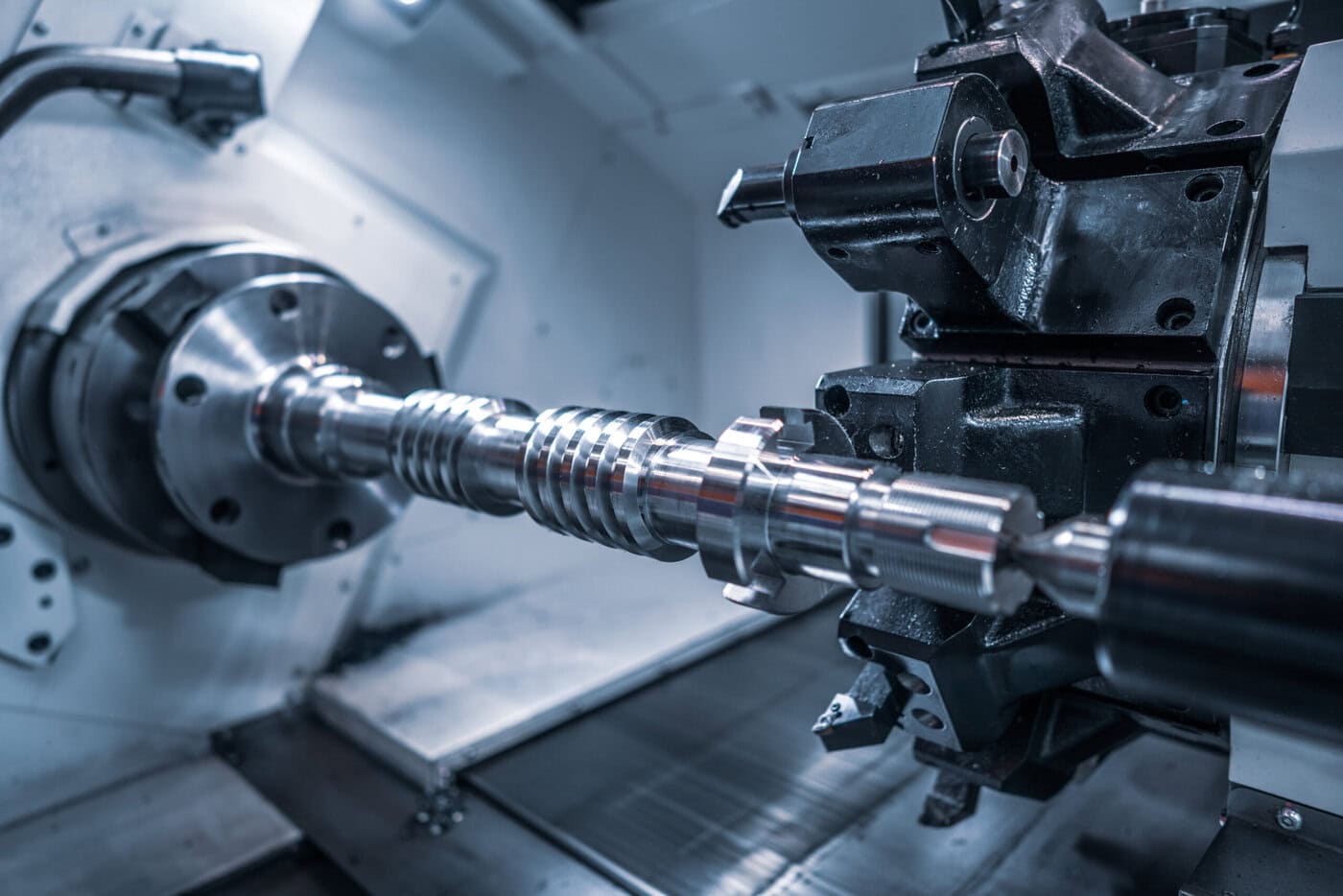

Shafts and axles

As a lower-cost option, you can use 1045 carbon steel to create axles that can handle impressive dynamic forces.

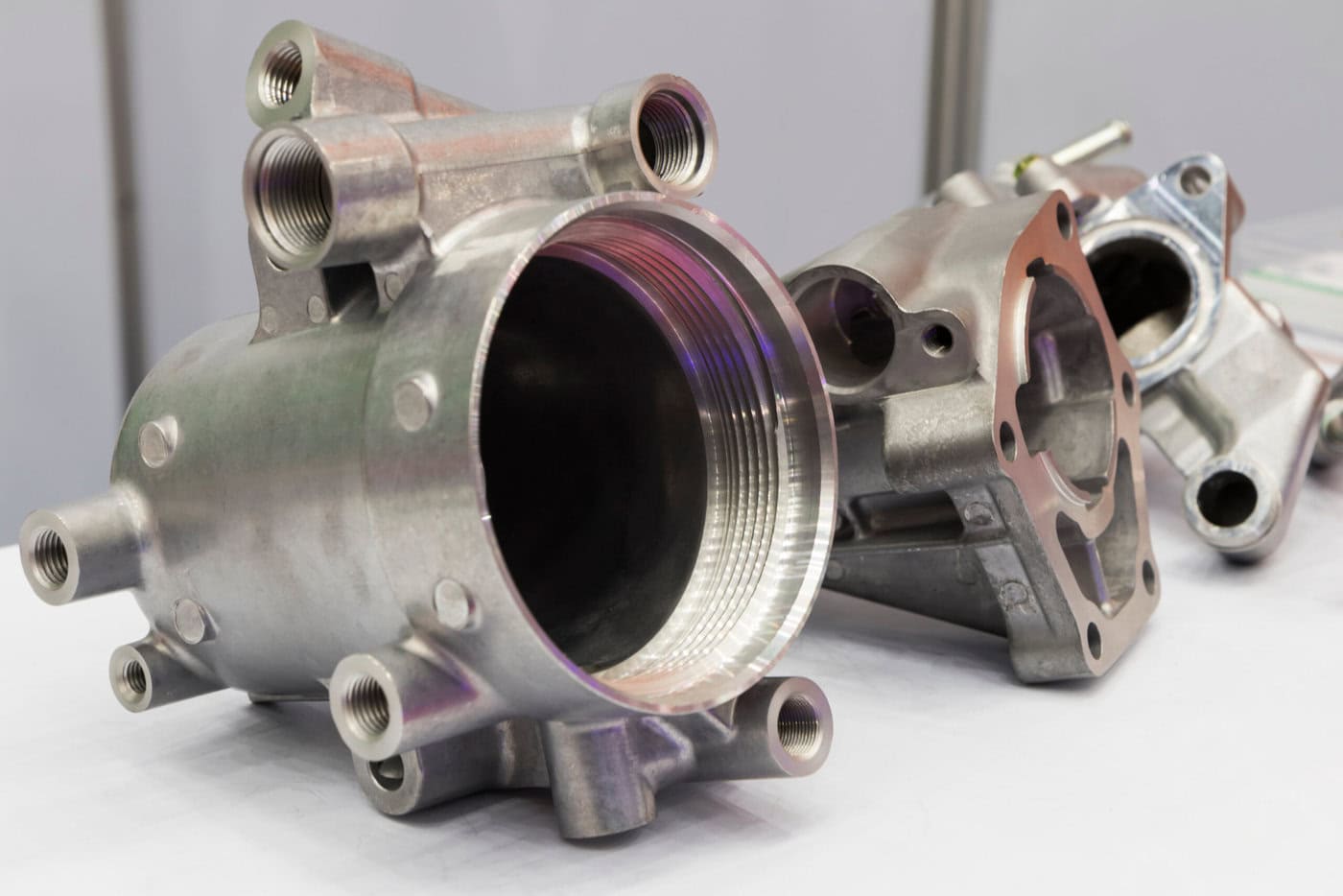

Bushings

Press-fit bushings or sleeves are made out of 1045 carbon steel since it has good strength and the ability to be hardened.

Brackets and fixtures

Brackets and fixtures can be made out of standard 1045 steel, or they can be additionally powder-coated to avoid corrosion. This utilizes the cost-to-strength ratio of 1045, allowing you to get functional parts without overpaying.

Rods and pins

Generally speaking, 1045 can be used in rods or pins that don’t need to be highly corrosion resistant, or are going through finishing steps to help with the longevity of these parts.

Inspection tools or jigs

We make a lot of custom tools and jigs out of 1045 since it is low-cost, easy to work with, and incredibly versatile.

Strengths and Limitations of 1045 Carbon Steel

We create 1045 steel parts for a number of companies across industries, and the popularity of this alloy is due to some major strengths:

Strengths:

- Great strength-to-cost ratio. As far as metals, 1045 carbon steel has one of the best strength-to-cost ratios on the market. It offers high strength at a lower cost.

- Easy to machine. As a softer steel, 1045 is easy to machine and form, allowing us to create custom steel parts for our customers.

- Can be heat-treated. Another added benefit of 1045 carbon steel is its ability to be heat-treated to create a more durable and long-lasting part.

- Better wear resistance. With better wear resistance, your parts will resist wear and abrasion, so you can use 1045 to create dynamic parts.

- Easily available and more affordable. 1045 carbon steel is one of the more commonly-available steel alloys, making it really easy to find the perfect stock shape and save money on fabrication.

Limitations:

- Poor corrosion resistance. We often suggest using powder coating or plating to ensure your 1045 carbon steel parts can resist corrosion, since this alloy is naturally very poor at doing so.

- Lower toughness and durability. There are a lot of other steel alloys that offer better hardness and durability levels, but those alloys often cost more and are more difficult to machine.

- Not great for welding. We can weld 1045 carbon steel, but it requires some preheating and post-weld stress relief to prevent cracking, so make sure you pick an experienced machine shop to weld your 1045 parts.

- Can fail under prolonged heat exposure. One big limitation is that 1045 carbon steel will lose strength and ductility as it gets exposed to prolonged high heat, or if the part goes through multiple heat cycles.

Metals Similar to 1045 Carbon Steel

1045 carbon steel has a lot of great features, but it might not be the right material for your project. If that’s the case, here are some other metals to consider:

1018 steel

has a lower carbon level, which means less strength in exchange for better weldability.

4140 alloy steel

offers better heat resistance, better fatigue performance, and higher strength, but it is more expensive.

A36 steel

is a low-carbon steel that is mostly used in structural applications.

1215 steel

is perfect for simple parts since it has better machinability.

304 stainless steel

is a corrosion-resistant option that works in high-moisture applications, food-grade environments, and industrial settings alike.