Intro

We noticed that a lot of people use the terms “jig” and “fixture” interchangeably. These two terms are very different and describe separate parts. In this guide, we’ll explain what a jig is, what a fixture is, and when you might use either option. We’ll even give some examples of both product types.

What Is a Jig?

A machining or manufacturing jig is more of a guide. It helps line parts up so a machine can cut a number of identical parts back-to-back as part of one big project.

They’re usually very customized, and they might be made before a big project is started.

You can use a jig for drilling, boring, reaming, cutting, and tapping a piece of metal, wood, or plastic. In some cases, a jig is just a corner that you can butt your raw material up to, and it tells you where you should cut the total length down to.

What Is a Fixture?

A fixture is more complicated than a jig. A fixture needs to firmly hold the piece while it’s being machined.

It has to stand up to the heat, mechanical force, and oil while the part is getting cut, drilled, machined, bored, or turned.

The fixture has to be set up so that your part can be precisely measured and worked on. If the fixture or part slips during a machining operation, the whole part will need to be remade.

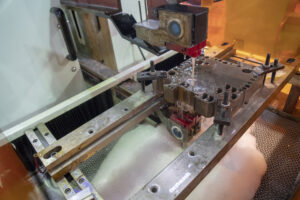

As a result, you’ll typically see fixtures used on heavier-duty machines, rather than just a simple drill press. On CNC milling machines, fixtures are a must-have.

Fixtures can also be used on customized parts as part of larger projects, just like jigs.

Types of Fixtures

There are a few different types of fixtures. Let’s review them so you have a better picture of what we’re talking about.

A Milling Vice

One of the more popular types of fixtures is a milling vice. In fact, this is probably where most people’s imagination goes when they see the word “fixture”.

A milling vice is a way to clamp down material on your CNC milling machine. Two, flat plates clamp together on the material very tightly. You’re left with a rigid hold on the part. Now, you can start machining the part and you know it won’t go anywhere.

It’s the same as a tabletop vice that you might have seen in the past: two strong jaws are pulled together as you turn the handle. If something is between the jaws, it will be clamped and held in position.

If you try milling a piece of metal without a vice, the part will be pushed out of position and fly off the machine.

A T-Slot Setup

A lot of milling machines have a T-slot table. This allows a T-slot clamp or other workholding devices to fit in position and hold down material.

This is not the same as a milling vice — although a vice could fit into a T-slot.

The fixture can typically slide along the T-slot channel, and there’s some key to lock it in position. This gives a lot of flexibility, allowing you to work on larger pieces of material and handle more obscure cuts.

You can either buy a pre-fabbed T-slot vice, machine your own, or buy one and customize it.

Types of Jigs

Next, let’s review different types of jigs. Remember, these are different ways to guide drilling or cutting operations.

Drill Jig

A drill jig might be the most popular type of jig. It’s a plate with a series of holes in it. Each hole is a different size, and it typically has a metal-reinforced inner diameter.

You would put this jig on top of your part and use your drill bit within the jig. It gives you a nice guide to ensure the cut is flush and square as you cut material.

You might also have a custom drill jig that shows you where on the part you need to drill, and how large the hole needs to be. You would hold this jig over your raw material, and drill your hole.

Box Jig

A box jig is a great way to machine multiple faces of a part within one jig. It typically has a face or two that can be pinged together with your material in between. Both faces of the jig have different holes, features, or cutouts.

You can put a piece of metal in the box jig, line up the material, then use the holes on the jig to cut directly into the metal.

It’s a lower-precision method, but it’s great for quickly making a series of holes on identical parts.

Sandwich Jig

A sandwich jig works how you might imagine: there is a plate on the top and bottom, and material goes in the center (typically sheet metal). The top and bottom faces have matching bolt patterns that line up.

After loading in the material, you can drill directly through the holes until your bit punches through the material.

Since the metal is held between both faces of the sandwich jig, it won’t warp or bend during the drilling operation. The holes in the jig show the right location and size for the holes to be drilled.

Conclusion

Even though jigs and fixtures are different products, they are both equally viable in a machine shop. At Rapid Axis, we utilize both to deliver the best results with every project. If you want to learn more or get started with us, contact us today for a free quote.