Intro

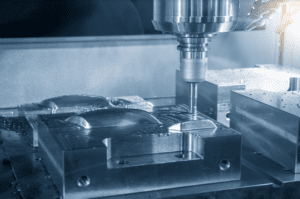

Using a CNC milling machine to fabricate a part is very common today. Even though modern 3-axis CNC machines are very advanced, they still require certain design considerations.

In this intro guide, we’ll explain some common design considerations. By the end, you’ll have a better understanding of how to design a part for CNC milling. Our tips will save time and money during the fab process.

Understanding Corner Radii

It’s important to point out that CNC milling machines use rounded tool bits to cut material. Why does that matter? It means that creating a square, 90-degree corner is borderline impossible.

Instead, CNC milling machines make rounded corners by default. This is a direct result of using rounded cutting bits.

Some machinists will slow down the machine when it starts cutting corners in order to minimize the radius, but you’ll still get a radius either way.

For external corners, keeping them square is easier since the tool can back away from the material before making the next cut. Internally, you’ll always be left with some form of radius.

In your design, you should include internal corner radii in most situations. Otherwise, you can expect a very high quote or confused call when fabrication starts.

Try to Minimize the Number of Setups

Before a machinist can start cutting on a CNC milling machine, they need to set up the material. This involves taking a block of metal, putting it in a vice on the milling machine, and tightening it in position.

If you have a six-sided cube where each face needs to be milled, this requires a minimum of six setups that the machinist has to do.

Each setup takes time and requires the machine to be zeroed again.

If you can minimize the number of setups necessary on the part, you’ll save time and money on each part. This is often easier said than done, and it can require sacrificing non-critical aspects of your design in exchange for a lower fabrication price.

In general, it’s a good idea to keep your designs as simple as possible. It helps with fabrication and ultimately saves you money.

All About Blind vs Thru Holes

Drilling a hole in a part comes with various levels of complexity. If the hole goes all the way through the part, it’s considered a “thru hole”. If it goes a certain depth into the part before stopping, then it’s a “blind hole”.

Drilling to a certain depth is trickier than drilling a thru hole. With this being said, there are two common options that can reduce manufacturing costs: either specify blind holes with very generous tolerances, or use thru holes whenever possible.

A loosely-toleranced blind hole means that the machinist doesn’t need to waste time ensuring a hole is exactly 0.500 inches deep. If you give a tolerance of plus or minus a quarter of an inch, you will reduce the time and effort required to make the part.

Of course, this isn’t always possible. There are countless applications where blind holes need to be a certain depth for the part to work. Still, you should consider thru holes whenever you can.

Use Standard-Sized Stock Material

A common problem that we see in our machine shop is designs that call for random and very specific overall dimensions. The overall dimensions are the total width, length, and height of your part.

Most machine shops buy stock material from various metal distributors. These huge pieces of metal typically come in standard sizes — like squares of metal that measure 1” by 1”. That means that we receive a long square of metal with those outside dimensions, and we would cut it to length before making your part.

If your drawing calls for a square of metal that measures 0.95” by 0.95”, it means that our machinist has to mill down the entire piece of stock material before we can start machining.

On the other hand, if your drawing says that a 1”x1” square is appropriate, we don’t have to do any rough cutting before we start.

This very simple difference could save hours on every part. This translates to a lot of money wasted machining down the part as well.

Our tip? Use standard-sized stock material whenever you get a chance. As a designer, it’s a good idea to look on Grainger or McMaster-Carr’s website to see stock material sizes before getting too far in your design. Using stock dimensions will make the CNC milling operation a lot smoother, faster, and less expensive.

Conclusion

Now you know more about CNC milling and how to design parts for this fabrication method. A well-designed part can save a lot of time and money on the machine shop floor during fabrication. Remember our tips and implement them on your next design. If you need fabrication help, reach out to our team at Rapid Axis. We are a full-service machine shop that can handle your CNC milling machine projects.