Electronics and Semiconductor

Our History with Electronics and Semiconductor Companies

It’s no surprise that the semiconductor and electronics markets continue to grow. If you want to beat your competitors and gain a larger market share, you need to pick the right machine shop. A fabrication partner can help you get high-quality parts at affordable rates, and deliver them quickly to your plant.

Our experts at Rapid Axis are here to deliver the best results for your electronics and semiconductor company. We offer manufacturing that includes CNC machining, sheet metal fabrication, 3D printing, tooling and molding, and finishing.

We can help you during the prototyping phase all the way until the final installation. Whether you need 1 part or 1 million parts, you can trust our team.

We’ve learned a lot throughout our history of working within Electronics and Semiconductor, and we bring a lot to the table. Consider us your one-stop shop for all things manufacturing and fabrication.

Why Electronics and Semiconductor Companies Choose Rapid Axis

There are a lot of reasons why electronics and semiconductor companies work with our team at Rapid Axis. Consider the following benefits and reach out to our team if you want to get started or learn more.

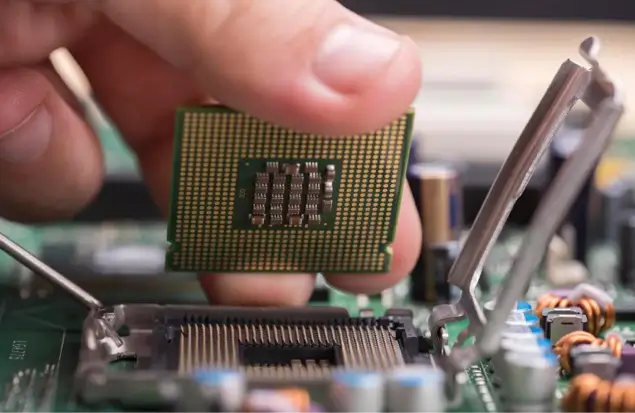

High-Precision Parts

In your industry, precision is one of the most important qualities. You likely have some tight tolerances that you’re working with, and you need all of the delivered parts to be dimensionally identical.

At Rapid Axis, this is no problem. We have decades of experience machining high-precision parts for a variety of different industries.

If a machine shop can’t reliably send you precision parts, it’s not worth wasting your time with them. Our goal is to deliver high-quality parts quickly, right to your loading dock.

Durable Parts to Minimize Your Downtime

We worked with one customer that told us that every hour of downtime in their plant equated to roughly a hundred thousand dollars of lost product. In an effort to avoid costly downtime, you need to use durable parts that utilize different finishing steps to make them even stronger.

We offer exactly that at Rapid Axis. We know that downtime can ruin your bottom line, so we ensure our products are durable and use high-quality materials. We never want one of our parts’ failure to be the reason why you’re losing money.

We also offer finishing steps like powder coating, heat treating, anodization, and electroplating to help make our parts even stronger. Since we provide all of these services, we can guarantee the quality of each finishing step we perform.

Complete Inspection Documentation

One way to give you peace of mind is through our inspection documentation. Based on what you’re looking for, we can put together official documentation that captures the measured dimensions of each part we make.

This helps you by providing a paper trail and guaranteeing the quality of our products. We stand behind every part we make, and this is one way to show that.

If your company has specific ways they need things to be inspected and written off, we’ll handle that. Our team understands that our customer’s way of working should take priority — especially if it means saving you time and hassle.

A Partner for Consumer, Commercial, and Industrial Companies

It doesn’t matter which sector of electronics or semiconductors you serve. We’ve worked with companies that served consumer, commercial, federal, and industrial customers.

The big distinction between these options is the size, scale, and requirements of your parts. Luckily, we have experience in all of the different sectors, so we can help you with your project.

We also have the capabilities to scale as your business grows. We can start with one-off 3D printed parts all the way up to millions of injection molded units a year.

Customized Solutions for Unique Problems

How many unique problems do you have in your operation? It could be something as specific as an underperforming machine in your process. To get solutions to your problems, you need a machine shop that is comfortable fabricating customized parts.

One of our biggest claims to fame is our comfort with making parts that have never been seen before. Since we are experts with CNC machining, 3D printing, sheet metal fabrication, production tooling, we can handle whatever design you throw our way.

We might even make custom workholding and jigs in our shop to help fabricate your parts. For larger orders, this will save you time, increase our throughput, and save you money.

High-Quality Material Selection

Different projects require different materials. We offer hundreds of different material selections in our facility. We can handle projects using metal, plastic, resin, and engineered materials. We carefully source all of our material vendors, ensuring we only get the highest-quality raw materials.

That helps us deliver even better parts. Low-cost material options might have defects and production issues that will ultimately hurt your process. Since we go through an extensive vetting process, you don’t have to worry about that.

Your part can only be as good as the material used to build it.

A Number of Finishing Options

When you have parts that are used in conductive or corrosive environments, there’s no need to panic. We understand that this situation occurs a lot, so we’ve put together a number of finishing options that we offer at Rapid Axis.

You can have your parts anodized, powder coated, or electroplated to keep corrosion away and prevent downtime in the future.