Consumer Products

Our History with Consumer Products Companies

The difference between a good product and a great product could be as simple as the manufacturing partner you choose to release your components. Your product is best represented by high quality and cosmetic components and Rapid Axis has experience at both limited release and mass production releases of a variety of consumer products.

Whether you’re in the product development phase or full production release, Rapid Axis can help. Our capabilities span from prototyping to mass production and we can support any quantity of component or need in between. We can handle a variety of materials from plastics to metals and support multiple manufacturing processes.

Our shop can create customized parts at fast turnarounds. In addition, we prioritize the quality of our parts, meaning that you only get the best products shipped to you. That comes from a long track record in the consumer space. We’ve created countless products across the market, and we’ve helped the company owners make a lot of money.

If you’re looking for a manufacturing partner, not just a shop, then you came to the right place. Feel free to contact us today to get started and start seeing results.

Why Consumer Products Companies Choose Rapid Axis

If it wasn’t clear, we have a lot of experience creating consumer products for different companies. We act as a partner throughout the process, helping you hit your timeline and stick to your budget.

Robust Prototyping Abilities

Every great product starts with a few series of prototypes. In our experience, prototyping is an iterative process. You want to tweak the design, test the part, then repeat the process until it’s perfect.

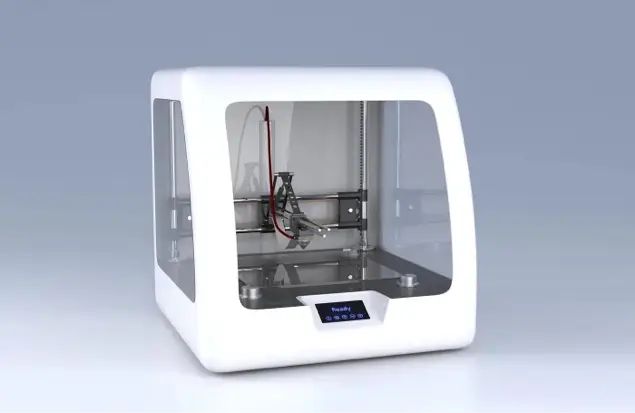

With our 3D printing expertise, we can expedite that process. You can feasibly go through three rounds of prototyping in a single week with our help.

We will 3D print the part and send it to your office so you can do testing and revisit the design. As you probably know, doing your due diligence during prototyping can save you countless hours and dollars in the future.

Our 3D printers can handle hundreds of different material options. We can even 3D print parts that are 100% solid metal via DMLS.

If the project won’t work on the 3D printer, we’ll use our CNC machinery or sheet metal to process your components. Allow our experts to worry about that — all you have to do is provide us with a model and design.

A Scalable Solution

As your business grows, so do your needs. If you’re stuck with a manufacturer that can only handle so many units a year, your growth will be stunted. Instead, you deserve a company that can help you scale from a few thousand dollars in sales to tens of millions a year.

That’s where our team at Rapid Axis really shines. We have the expertise to keep up with your demands as your company grows. We will seamlessly shift from one manufacturing method to the next, making sure that our shop isn’t bottlenecking your growth.

Our injection molding operation can also scale with you — we can create molds that produce multiple units at once, expediting manufacturing and keeping your costs low.

Fast Turnarounds

Often, there’s no time to waste when it comes to rolling out a new product. Your timelines are tight, and we get it. For that reason, we put a lot of effort into minimizing the time we spend making your product.

We expedite the manufacturing process and keep the turnaround times fast. At the same time, we offer high throughputs and incredible quality on every part that leaves our shop. This combination is imperative if you want to make a name for yourself in the consumer products space.

We want all of our customers to become “one of the big guys” in their market. One way to help achieve that is to get you your parts even faster.

A Partner Throughout the Process

Whenever you’re introducing a new product or revamping a previous one, you need someone you can trust in your corner. With a good manufacturing partner, you can focus on marketing and growing your brand while we handle making high-quality parts for you.

We’ve built a reputation supporting both design firms and OEM’s alike by providing end to end support during the product development lifecycle. As we mentioned, we can manufacture parts during the prototyping phase all the way through to full-scale production.

Our injection molding machines onsite can be loaded with dies that we customize and manufacture. We can create hundreds of thousands of units for you annually.

Allow Your Margins to Grow

Another key part of running a consumer products company is keeping your costs down. If you’re overpaying for manufacturing, you might become your biggest enemy. Pricing yourself out of a consumer space might be the sole reason why your product fails.

If you want to stay competitive and start picking up bigger market shares, you need to keep your margins wide and operating costs low. At Rapid Axis, our manufacturing costs less than the other guys who offer the same quality that we do.

Since you’re paying us less for your products, you can price your parts lower and stay ahead of the market. This helps you make more money, grow faster, and unlock your company’s potential.

Our shop is one of the rare exceptions where you don’t need to overpay for high-quality products. Thanks to our expertise and leadership, we can keep our costs low and pass the savings to you.