Automotive

Our History with Automotive Manufactures

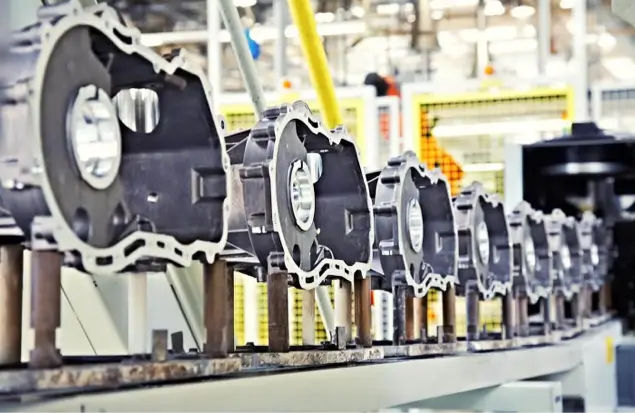

Rapid Axis has a long working history with both EV and traditional automotive manufacturers. We’ve supported companies such as Rivian, Lucid and Canoo with prototyping, small-batch orders, and full-scale production for a vast array of components. We’ve made products for the drivetrain, charging assembly, interior, and various mechanical subassemblies.

Rapid Axis is relied on for expeditious prototyping as well as mass production for multiple automotive organizations. Our versatility comes from our breadth of available services, which include machining, sheet metal, injection molding, and urethane casting. Our ability to deliver any number of high-quality parts on time and under budget makes us the winning choice for projects where budgets and schedules matter. If you have requirements within the automotive industry and are looking for a great shop with a long-running track record of success to support your needs, reach out to Rapid Axis and speak with one of our experts.

Why Automotive Manufacturers Choose Rapid Axis

To better understand why automotive manufacturers choose Rapid Axis, we’ve put together this short list. Automotive companies like the services we have to offer, and they appreciate the benefits of working with our shop.

Tight Tolerances

One of our biggest focuses is to offer tight tolerances. We understand that in order to be competitive in the automotive field, manufacturers need parts that can easily fit into their assemblies. Whether it’s part of the framework, a tie rod, sway bar, or just a cupholder, designing for tight tolerances is often unavoidable when designers are putting together an automobile.

At Rapid Axis, we offer tolerances that will match your control drawings. This allows for more design freedom and higher-quality assemblies.

High-Quality Products

With most of our automotive customers, quality is a big focus. Manufacturers are often using our parts for their final production runs. This means that the parts we manufacture will be seen by every customer moving forward.

With the wrong fabricator, you’ll get low-quality parts for your assembly. This could lead to end-user complaints, service issues, or even product recalls depending on what part the shop made.

To put it simply, you’ll be wasting your time and money in the future if you choose a low-quality shop. At Rapid Axis, we have a number of inspection steps in order to guarantee your parts were made within spec. We also source our raw materials from high-quality vendors and do material checks before our CNC machines start cutting.

Repeatable Prototyping for Iterative Designs

Prototyping is an essential first step for creating an automobile — especially with EVs, a largely unproven space. In order to get the best results in the long run, you’ll need to do cyclical, stress, heat, and dynamic testing today.

This means making a prototype and putting it through a series of tests. In our company’s business, we’ve helped countless companies go through their prototyping, whether it was for a mature design or a brand-new product.

Our prototype units are equally precise and high-quality as our production parts. This gives you the ability to perform accurate tests and get the best results before moving forward into large-scale production.

With our faster turnarounds and higher qualities, you can iterate designs and get a new-generation prototype back for testing in no time.

Choice of Manufacturing Processes

Another point to note is that automotive manufacturing doesn’t just rely on one machining process. A single automobile might utilize injection molding, 3D printing, CNC milling and lathing, and sheet metal fabrication all in one assembly.

The good news is that our shop offers all of these services and more. This allows us to take on more projects from automotive companies. Since we do all of these manufacturing steps plus post-processing in-house, we can keep costs lower, turnaround times quicker, and quality higher.

Other shops might bid out certain processes to other shops if they don’t have the capabilities. This can cut further into your tight profit margins and aggressive production timelines.

Small and Large-Batch Production

We have the means to produce small-batch units for prototyping as well as large-batch production parts for your newest car launch. Thanks to our CNC capabilities as well as full-scale injection molding processes, you can order parts in the 10’s, 100’s, or 1,000’s without any issues.

One of our production experts will help you understand the right manufacturing process for your demands, and we’ll provide a free quote to compare different fabrication options (whenever necessary).

In other words, you won’t need to rely on another manufacturer as your operation progresses. Finding three separate machine shops for the early, middle, and late stages of production requires too much time and effort. At Rapid Axis, we can walk through all three stages with you.

Long-Lasting Partnership

Rapid Axis’s mission is to develop long term relationships with Engineers and Buyers. Our goal is to offer a partnership to each of our automotive customers. As your product line develops, our partnership will, too.

With companies like Rivian, who approached us early in their production run, Rapid Axis has proven to be an invaluable company to work with. We can help a company from prototyping to full-scale production, and every step along the way.

Since our staff is full of manufacturing experts, we will provide guidance and expertise whenever you need it. From there, we’ll help you build tens of thousands of units as your company continues to grow into a globally recognized brand.