Intro

A lot of people who call us don’t know which manufacturing style is right for their project. Luckily our team is filled with expert machinists, so we know what options you have pretty immediately. However, we think it might help you to understand one of the more versatile options: fiber laser cutting.

In this beginner’s guide, we’ll show you how fiber laser cutting might be right for you. We’ll tell you what it is, how it works, when you can use it, and some major advantages of this fabrication option.

What Is Fiber Laser Cutting?

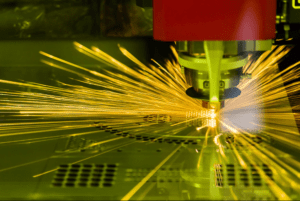

We should start with a definition. Fiber laser cutting is a manufacturing method that works a lot like a plasma cutter (since it’s a form of laser cutter). The quick version is that a stream of light is concentrated into a beam, and the beam cuts through metals.

The key difference is that a fiber laser cutter uses fiber optic cable to channel and amplify the light into a beam.

Compared to traditional laser cutters, a fiber laser cutter is significantly more efficient, cuts faster, saves money, and allows for more material options.

The laser works on a 2-dimensional plane, specifically the XY-plane. This means that it can only cut “flat” models and doesn’t offer 3D machining like a CNC mill or 3D printer.

The laser cuts the outline of the part you want to make. It can also cut internal geometries and features. The laser is positioned on a machine head that moves on a gantry. The tracks will move the head around, while the laser cuts out material underneath it.

When Can You Use a Fiber Laser Cutter?

You can use a fiber laser cutter whenever you’re cutting flat pieces of paper products, wood, plastics, or metal.

You can make bent metal pieces by creating flat versions of the piece on a fiber laser cutter.

In our shop, a vast majority of uses for fiber laser cutters are either sheet metal parts or plastic pieces.

Benefits of Laser Cutting

There are plenty of benefits of laser cutting over other manufacturing styles. To better understand why you might use a fiber laser cutter, consider the following benefits.

The Cutting Speed Is Very Fast

It’s always fun to watch a fiber laser cutter get to work. It moves around very quickly, and you’re left with a perfect part when it’s done.

We typically load giant sheets of metal onto the table of the fiber laser cutter, and have the tool create multiple different parts at once. As long as we orient and stagger the parts correctly, we can create impressive quantities of parts with very little scrap material left over.

It also means that we can cut all of the parts using a single operation, which saves a lot of time.

Can Hit Tight Tolerances

Any form of laser or plasma cutter can hit some very tight tolerances. This is even more impressive if you consider the speed in junction with accuracy — typically you have to choose one or the other when it comes to fabrication.

Can Create Square Corners

A big caveat with traditional machining is that it’s very tough to get truly square corners. Thanks to radii and tool chatter, you might be left with a rounded corner, especially if it’s an internal feature.

With fiber laser cutters, we can tell the program to create 90-degree, square corners. This can be done by either pausing the cutting operation while the head repositions, or creating a “dog-ear” corner.

The Machine Runs Itself

With most projects, the machinist only needs to load material and occasionally set up a program. Once the machine starts, it can run on its own without any supervision.

There are times in our shop when we have our laser and plasma cutters running while the machinists are using other machines elsewhere. Doing this reduces manhours spent on every laser-cut part.

Lower Cost Per Part

If you combine the fact that the machine requires less energy to run, fully autonomous operation, the operation is faster, and material waste is lower, you’re left with a single feature: lower cost per part.

Allows for Intricate Geometries

Since the cutting feature is a head that’s connected to a 3-axis gantry, we can cut some very intricate parts on our fiber laser cutter. Traditional machining has a lot of constraints when it comes to motion, what types of patterns can be made, and how a tool can be operated.

With fiber laser cutters, most of these rules go out the window. You can create a jigsaw puzzle with this tool pretty easily, so that should show you how complicated the parts can get.

Conclusion

Now you’re a fiber laser cutter expert. We just covered what they are, how they work, and some major advantages of using them. If you want to know if this option is right for your next project, reach out to our experts today. At Rapid Axis, we have laser cutting capabilities in-house, so we can handle the project for you. Our goal is to deliver high-quality parts that exceed your expectations.