No matter what your industry, the speed and efficiency of your product development cycle can make or break your success. One of the key factors in accelerating this cycle is the use of advanced mold and tooling technologies. These technologies not only streamline production but also ensure higher quality and consistency in your parts.

In this article, we will explore how the latest advancements in tooling and molding can enhance your product development cycles and position Rapid Axis as your go-to partner for these services.

The Importance of Advanced Mold and Tooling

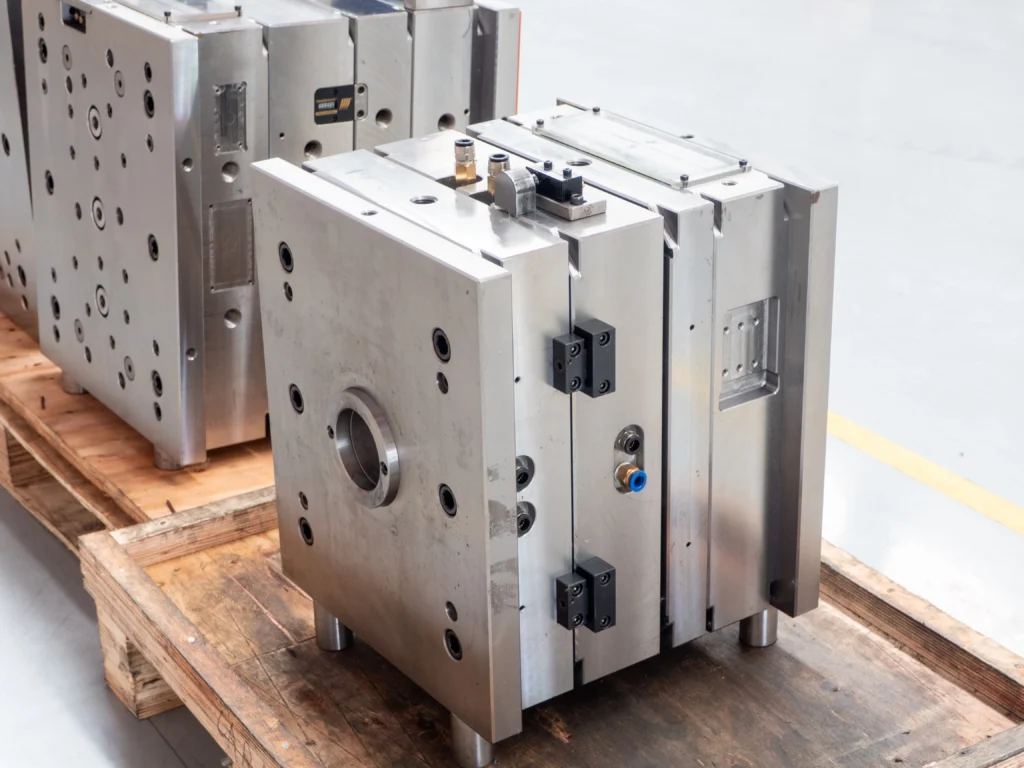

In the world of manufacturing, the term “tooling and molding” refers to the processes used to create molds and tools that shape and form materials into finished products — such as the machined chunk of steel that’s used in an injection molding operation.

Advanced mold and tooling technologies have revolutionized these processes, providing numerous benefits that can significantly impact your product development cycle.

Speed Up Product Development With Tooling and Molding

One of the most significant advantages of advanced mold and tooling is the ability to speed up the product development cycle. Here’s how:

It Makes Rapid Prototyping Possible

Advanced tooling techniques, such as CNC machining and 3D printing, allow for rapid prototyping. This means you can quickly create and test prototypes, make necessary adjustments, and move to production faster than ever before.

It Delivers Precision and Accuracy

With modern mold and tooling technologies, you can achieve higher precision and accuracy in your prototypes and final products. This reduces the need for multiple revisions and accelerates the approval process.

Take Advantage of Reduced Lead Times

By utilizing high-speed CNC machines and efficient tooling designs, production lead times are significantly reduced. This means your product can go from concept to market much quicker.

You Can Enjoy Improving Efficiency

Efficiency is another critical factor that advanced mold and tooling technologies bring to the table. Let’s look at some ways these technologies improve efficiency:

Automation Makes Everything Faster and Less Error-Prone

Automation in tooling and molding processes minimizes human error and increases production efficiency. Automated systems can handle complex tasks with precision, ensuring consistent quality and reducing the time spent on manual interventions.

It Enables Material Optimization

Advanced tooling techniques enable better material utilization, reducing waste and lowering costs. With precise cutting and forming technologies, materials are used more efficiently, leading to cost savings and a more sustainable production process.

It Offers Greater Versatility

Modern mold and tooling technologies offer greater versatility in terms of the materials and designs that can be used. This flexibility allows for more innovative product designs and the ability to adapt quickly to changes in market demand.

The Top 4 Benefits of Advanced Mold and Tooling

To fully appreciate the impact of advanced mold and tooling, it’s important to consider the specific benefits they offer:

- Enhanced Quality: Advanced technologies ensure that each part produced meets stringent quality standards. This results in fewer defects and higher customer satisfaction.

- Cost Savings: Although the initial investment in advanced tooling may be higher, the long-term cost savings from reduced waste, lower labor costs, and increased production efficiency are substantial.

- Scalability: Advanced mold and tooling technologies allow for easy scalability. Whether you need a small batch of prototypes or a large production run, these technologies can accommodate your needs efficiently.

- Customization: With advanced tooling, customization is more accessible. You can create intricate designs and tailor products to specific customer requirements without compromising on quality or efficiency.

A Quick Note on the Drawbacks of Advanced Mold and Tooling

While advanced mold and tooling offer numerous benefits, there are some drawbacks to consider:

- High Initial Costs: The upfront investment in advanced mold and tooling technologies can be substantial. This includes the cost of equipment, software, and training for staff. Rapid Axis has already made this investment for you, though.

- Complexity: The sophistication of advanced tooling technologies can add complexity to the production process. This may require specialized knowledge and skills, which could lead to a steeper learning curve for your team. Thankfully, this also doesn’t apply to you because you have Rapid Axis at your disposal and we are experts!

- Maintenance: Advanced tools and machines require regular maintenance to ensure optimal performance. This can add to the operational costs and require additional resources. Again, Rapid Axis tackles this problem so you don’t have to worry about it.

Real-World Applications

The practical applications of advanced mold and tooling are vast. For instance, in the automotive industry, precision molds are essential for creating complex parts like engine components and interior features. In the medical field, advanced tooling ensures the production of high-quality, reliable medical devices.

Contact Rapid Axis About Our Tooling and Molding Services

Incorporating advanced mold and tooling technologies into your product development cycle can lead to significant improvements in speed, efficiency, and overall product quality. At Rapid Axis, we specialize in providing top-notch tooling and molding services that leverage the latest technologies. Our team of experts is dedicated to helping you streamline your production processes and bring your products to market faster.

Whether you are in the automotive, medical, aerospace, or consumer products industry, our advanced mold and tooling services can provide the precision and reliability you need. Contact Rapid Axis today for a free quote and let us help you enhance your product development cycle with our state-of-the-art solutions.