Intro

Most aerospace companies need hard-working parts that are lightweight, cost-effective, and can be repeatably made. For many, CNC manufacturing is the go-to option for parts like this.

Partnering with a machine shop that can handle high-quality CNC manufacturing is a great option for any aerospace company. Our fabrication experts at Rapid Axis put together this quick guide to better explain the benefits of CNC manufacturing for any aerospace company.

Better Precision

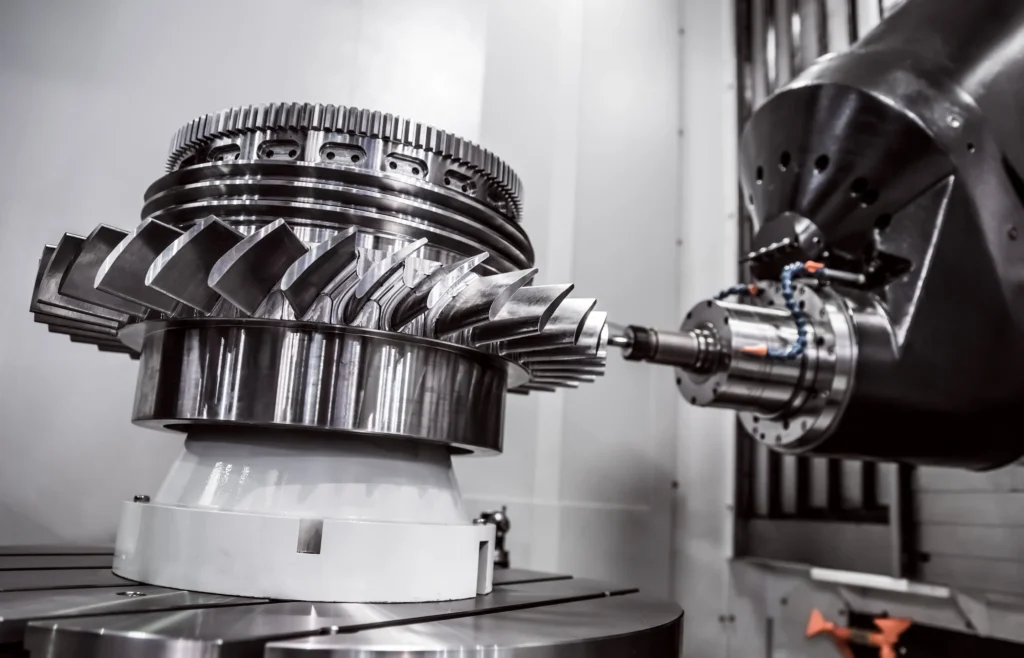

From turbine blades to fuselages and electromechanical parts, CNC machining offers impressive precision that other fabrication offers cannot match. With slower machine speeds and higher-quality raw materials, our team can achieve even better precision than you might expect.

There’s a reason why CNC machinery is so important for any precision machine shop — a CNC station can be fine-tuned to meet your tightest tolerances.

Consistent Results

In addition to being precise, CNC machinery is also very consistent. This is great news for aerospace companies that need dozens of dimensionally-identical parts. One of the many applications of CNC machinery involves projects that need small batches of identical parts made with high precision.

Faster Turnarounds

With CNC machining, the right programming can automate most or all of the manufacturing operation. In many cases, our operator simply needs to load a block of material in the correct orientation, then our CNC machines do everything from there.

With this level of automation, we can greatly expedite any project. With our help, you can unlock faster turnarounds on any part you need to be manufactured.

Reliable Partnerships

CNC machinery is incredibly reliable, and it can lead to very beneficial partnerships with your machine shop of choice. At Rapid Axis, you can leverage all of our CNC machinery and highly trained staff to reliably make your parts. From a small custom bolt to a massive fuselage, a CNC machine can reliably tackle a whole host of projects.

In other words, choosing the right CNC manufacturing company can save you a lot of headaches in the future. You don’t need to remember a dozen different manufacturing companies, just remember Rapid Axis and allow us to repeatedly exceed your expectations.

Reliability in machining is imperative for every aerospace company. It ensures that you get the right part, every time.

Ability to Fabricate Complex Parts

CNC machinery does a great job of tackling complicated designs. With different levels of automation and multiple axes to work with, our CNC machinists can program your most intricate part and make it a reality.

Trying to do the same project with traditional non-CNC machines is borderline impossible. Our CNC milling machines can work with non-standard angles, non-nominal hole sizes, and non-traditional materials to create one-off custom aerospace parts.

Various Material Options

One of the biggest benefits of CNC machining is the ability to work with various materials. Our shop can handle aluminum, steel, titanium, multiple plastics, brass, and unique metal alloys with no problems. The result? More customization for each of your parts.

You can hand-pick the exact alloy of aluminum that you’d like to use, or ask for our professional opinion. Either way, our CNC machines will make high-quality parts out of almost any material you can imagine.

Optimize the Performance of Each Part

With most aircraft, every part needs to be optimized to be as strong, lightweight, and reliable as possible. This often involves FEAs and engineering calculations to perfect each design. However, a big variable comes from the machine shop you choose.

Picking a machine shop that can’t handle precision CNC work might mean that all of your effort spent optimizing your design goes down the drain. Something as simple as choosing the wrong stock material could result in a part that fails after one use.

In many applications, there’s no room for error — you expect your machinist to make every part perfectly. With the help of our CNC machines and expert staff, our team at Rapid Axis can step up to the challenge. With our fabrication expertise, you can optimize the performance of each part that we make.

Conclusion

Picking the right CNC machine shop can save you a lot of time and money during each aerospace project. The benefits of CNC machinery in your aerospace manufacturing project include faster turnarounds, better reliability, great precision, and the optimization you need. For your next manufacturing project, consider Rapid Axis.

Our highly-trained team has access to multiple CNC machines that can meet your expectations. With decades of experience, you can trust our team. Get a free quote today.