CNC machining is the process of using Computer Numerical Control (CNC) machines that provide a level of precision, accuracy, and efficiency that traditional hand-operated machinery cannot. CNC machinery takes many different forms, from milling machines to lathes and drill presses, but the defining qualities are the same across the board: these machines use computers to read and understand the position of the machine.

Many CNC machines offer automation, which makes them a great pick for making plastic prototypes. In this quick guide, our manufacturing professionals will discuss 8 reasons why you might consider CNC machining for making your plastic prototypes.

1. Precision and Accuracy

CNC machining stands out for its exceptional precision and accuracy, which is crucial in prototype development. With bad fabrication and incorrect measurements, your prototypes can mislead your team and make you think the part will fit within the assembly when, in reality, it won’t work.

When working with plastics, the precision of CNC machines ensures that every detail of your design is captured accurately. This is particularly important for prototypes that require intricate details or need to fit precisely with other parts.

CNC machines can achieve tolerances that are often difficult to replicate with other manufacturing methods.

2. Repeatability

One of the standout advantages of CNC machining is its repeatability. Once a design is programmed into the CNC machine, it can produce numerous copies of the same prototype with exact precision. In other words, we can set up a program to create a dozen identical prototypes for you without any issues.

This consistency is vital for engineering departments that need to test multiple prototypes under the same conditions, or when moving from prototyping to full-scale production. The ability to reproduce designs without variation ensures reliability and quality in every piece.

We always suggest making a few prototypes so you can perform destructive testing without losing time.

3. Customization

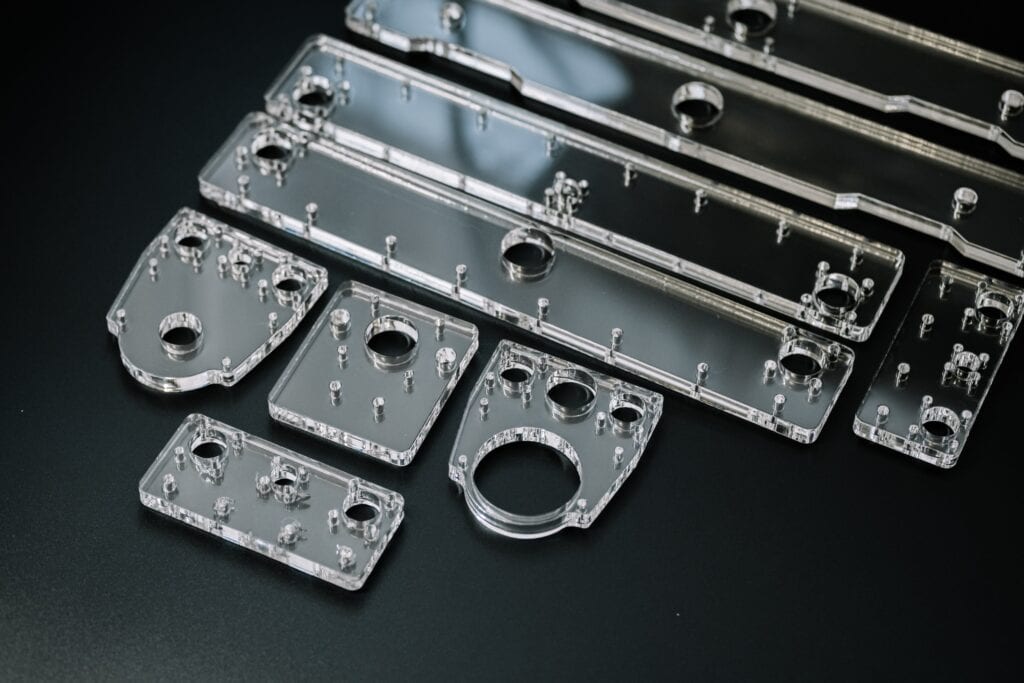

CNC machining offers unparalleled customization opportunities. Whether you need a unique shape, specific dimensions, or a complex design, CNC machines can cater to these requirements with ease. This level of customization is a significant advantage when creating prototypes, as it allows engineers to experiment and innovate without the constraints of standard manufacturing processes.

Our CNC capabilities allow us to make completely unique and one-off parts for your prototyping applications.

4. Wide Range of Plastics Compatibility

CNC machines are compatible with a wide range of plastic materials. We can create parts from common plastics like ABS, nylon, and polycarbonate, or we can create prototypes with specialized engineering plastics like PEEK — all on the same CNC machine.

This versatility means you can select the material that best fits the specific needs of your prototype, whether it’s for strength, flexibility, heat resistance, or aesthetic appeal. This compatibility also allows for testing different materials to determine the best option for your final product.

5. Speed and Efficiency

Machining plastic with a CNC is a time-efficient process, making it ideal for quick prototyping. The speed of production means that you can move from design to finished prototype quickly, accelerating the development cycle.

With faster turnarounds, you can achieve even faster iterations and revisions on your designs and get to final implementation even sooner. This is even more important in competitive markets where speed to market can be a critical factor.

6. Create Solid Plastic Parts

If you want stronger parts, then you’ll need to have solid plastic parts. While 3D printing is also a great option for prototyping with plastic, 3D-printed parts are often hollow and not nearly as strong as a solid block that has been CNC-machined. CNC-machined solid plastic parts offer strength, durability, and longevity that other fabrication options can’t offer.

7. Integration with Modern Design Software

Modern CNC machines integrate seamlessly with advanced design software, enabling engineers to transfer their digital designs directly to the machining equipment. This integration reduces the risk of errors in translating the design into a physical prototype.

The ability to use sophisticated Computer-Aided Design (CAD) models directly enhances the accuracy and feasibility of complex designs.

8. Surface Finish Quality

CNC machining provides excellent surface finish quality. The precision of the machines ensures smooth surfaces that often require minimal post-processing. This quality is particularly important for prototypes that need a high-grade finish for functional testing or aesthetic purposes.

With a CNC-machined plastic prototype, it will be much easier to sell your idea to stakeholders and investors, while getting valuable data from a professional-looking part.

Conclusion

Choosing CNC machining for your plastic prototypes is a great option. CNC machining is a quick way to make high-quality, strong, reliable parts that can give you valuable insight into the validity of your design.

For production-quality prototypes made out of CNC-machined plastics, consider working with our team at Rapid Axis. We’ve helped countless engineering companies get the prototypes that they deserve. We are a full-service machine shop that can manufacture your prototypes and send them directly to your facility in no time. Get a free quote today.