Which Aluminum Alloy to Use for Die Casting

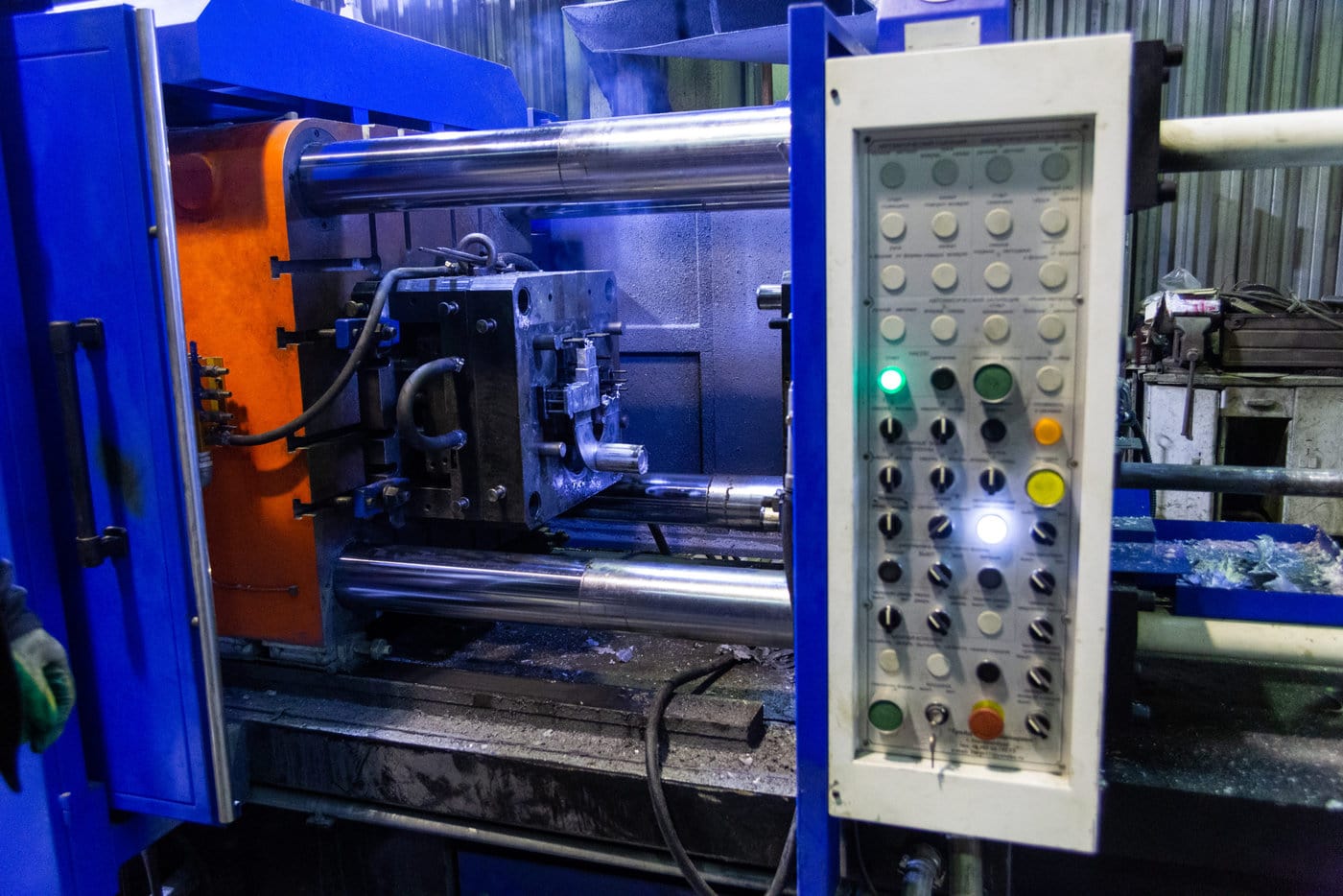

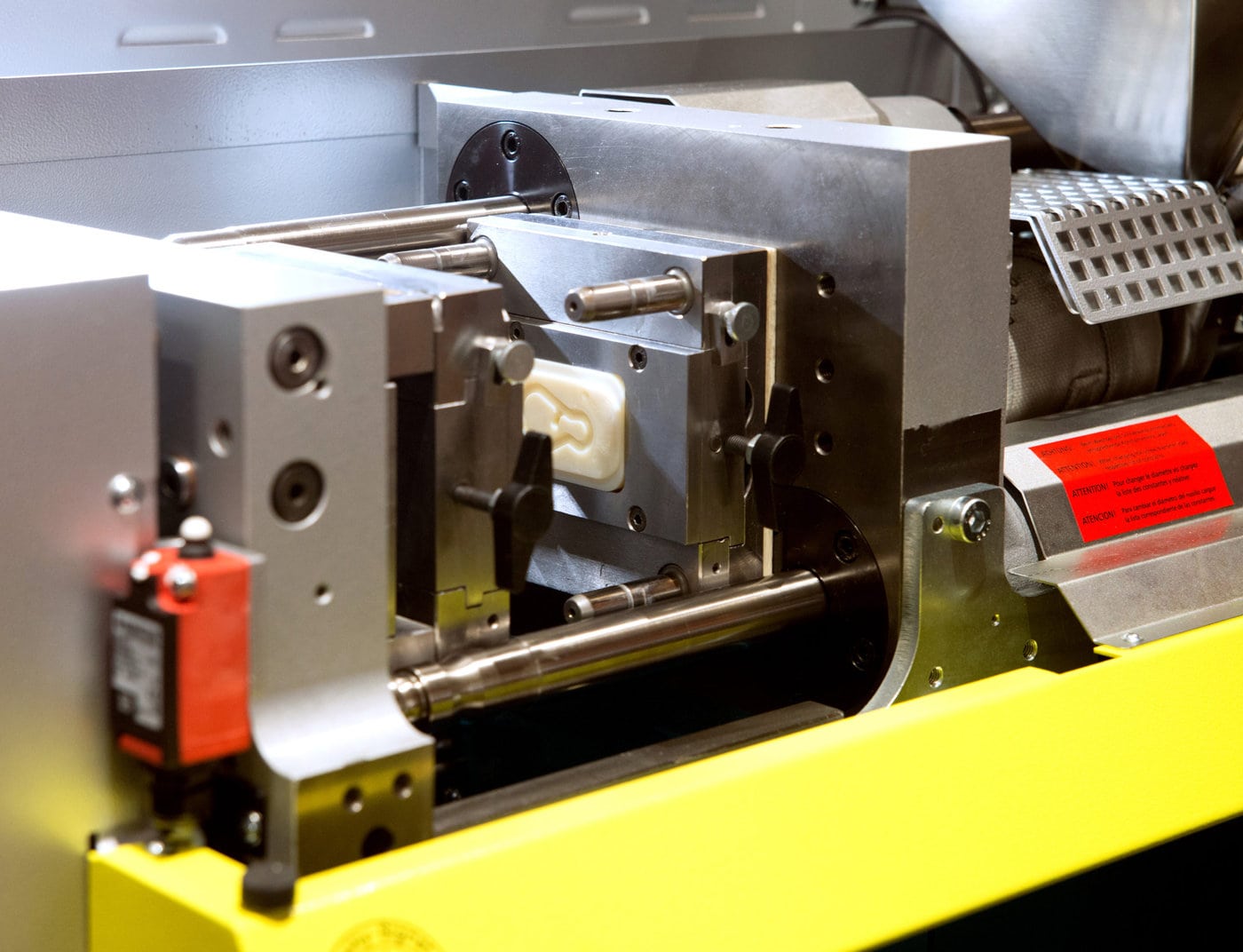

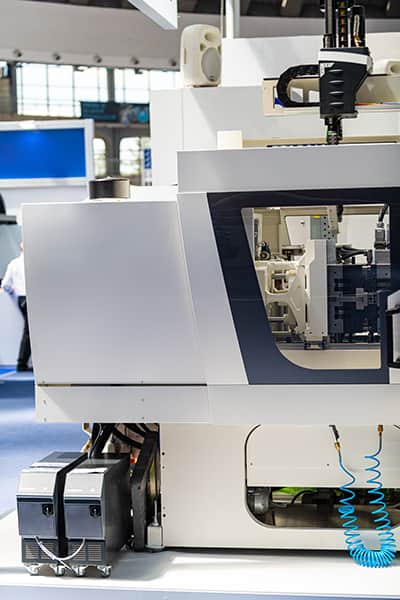

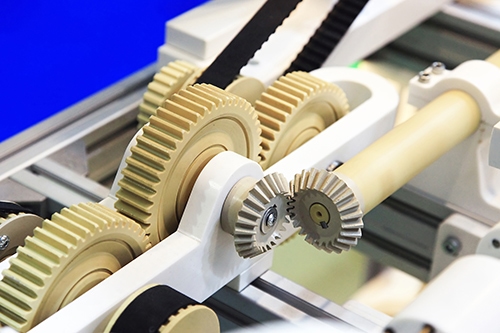

Intro Die casting is a great way to get a number of nearly identical parts made out of metal. The process is faster than most traditional machining options, and the final part is typically less expensive. The biggest driving decision in die casting is the…