What Is Injection Molding? Plus, Benefits and Tips for Success

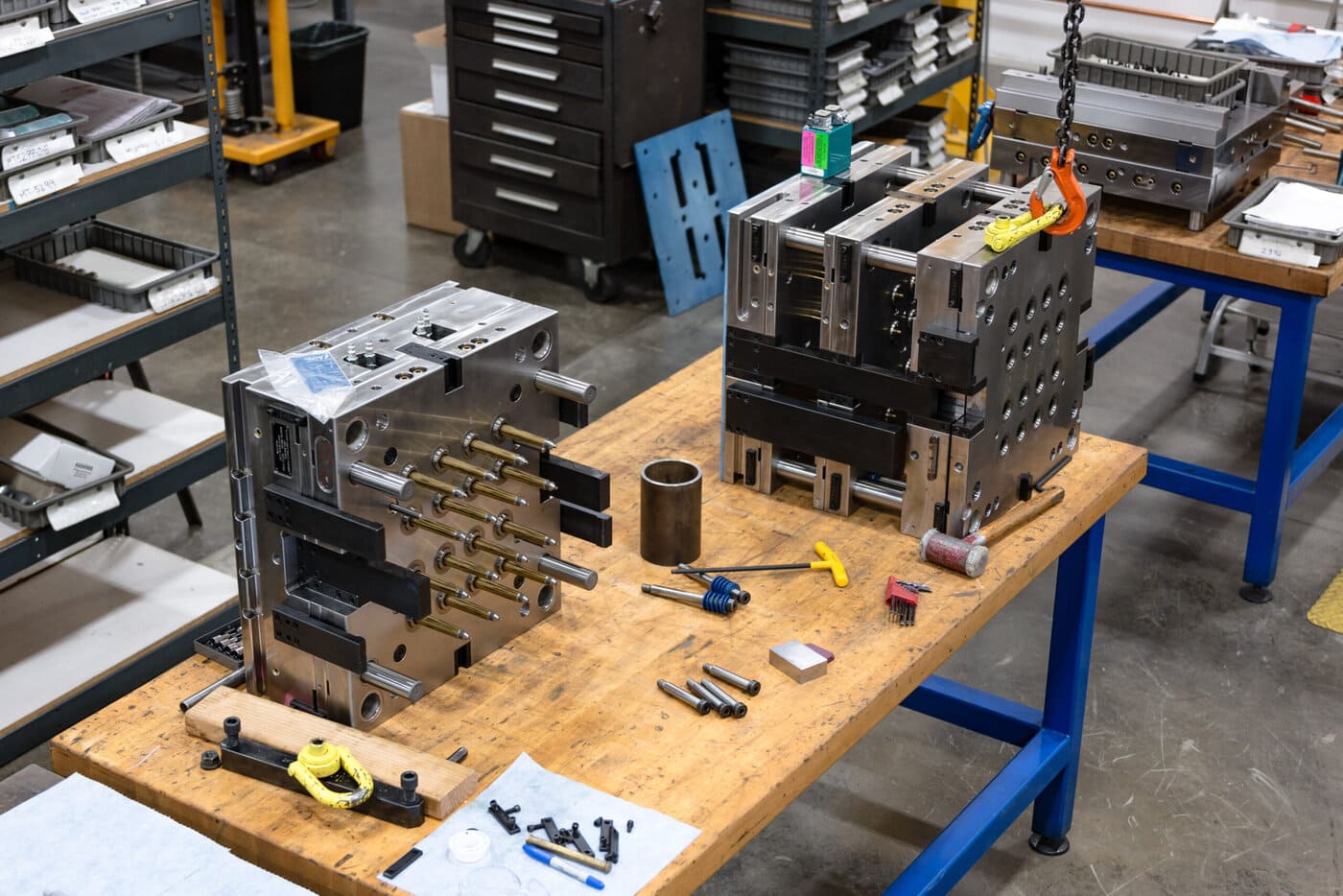

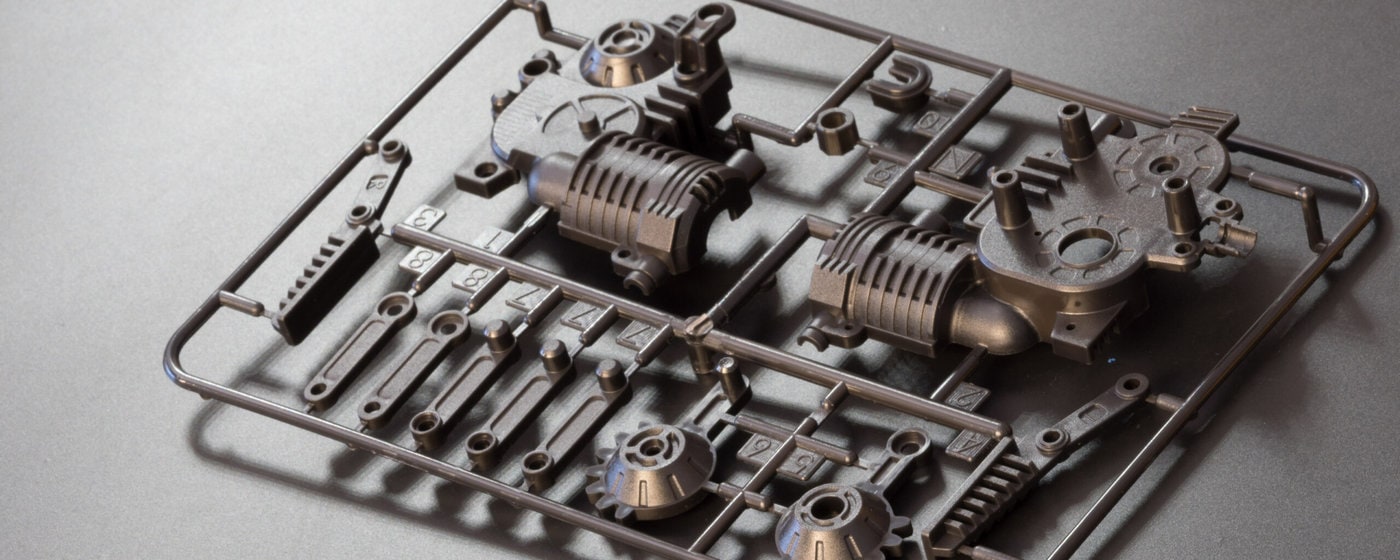

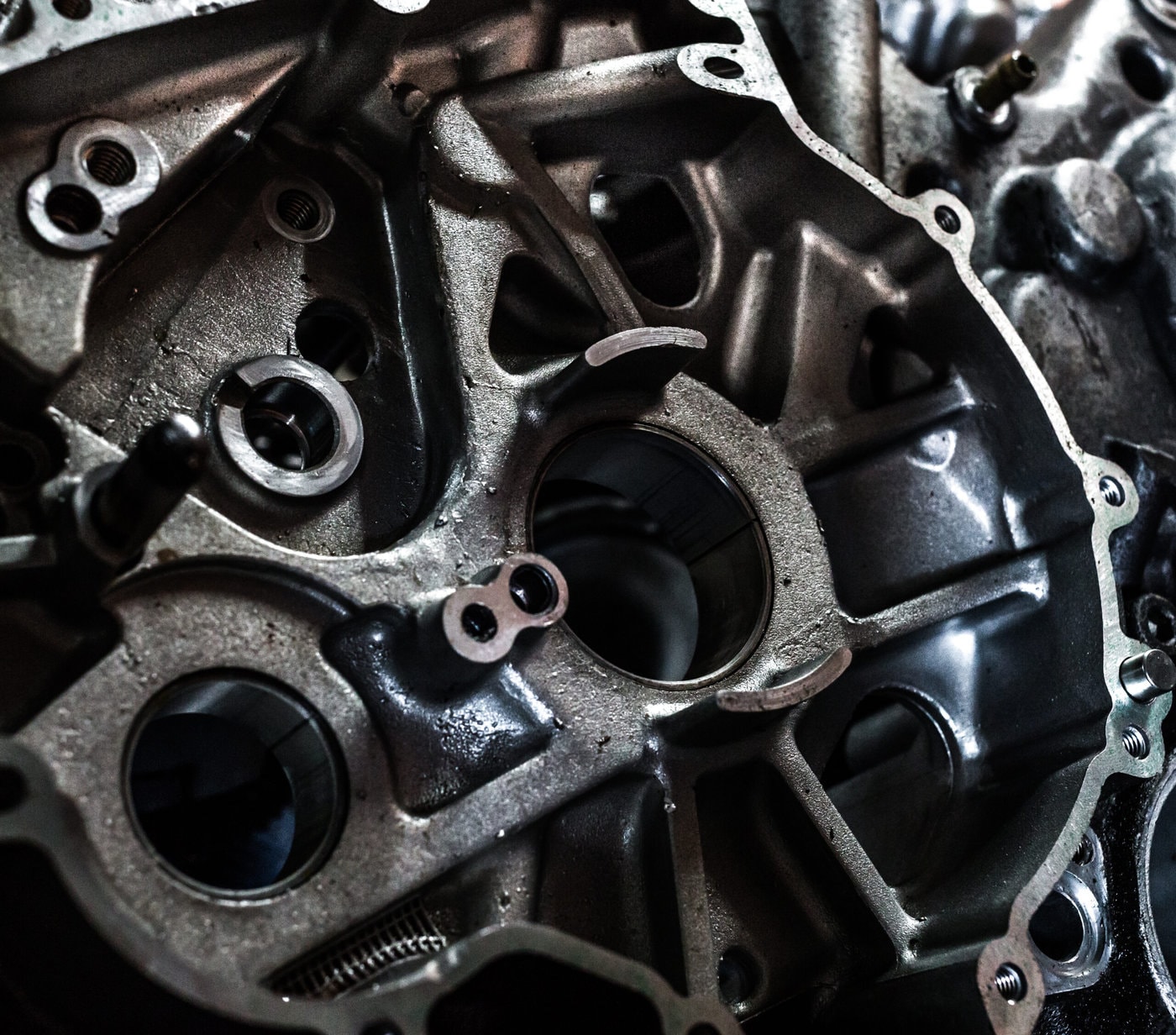

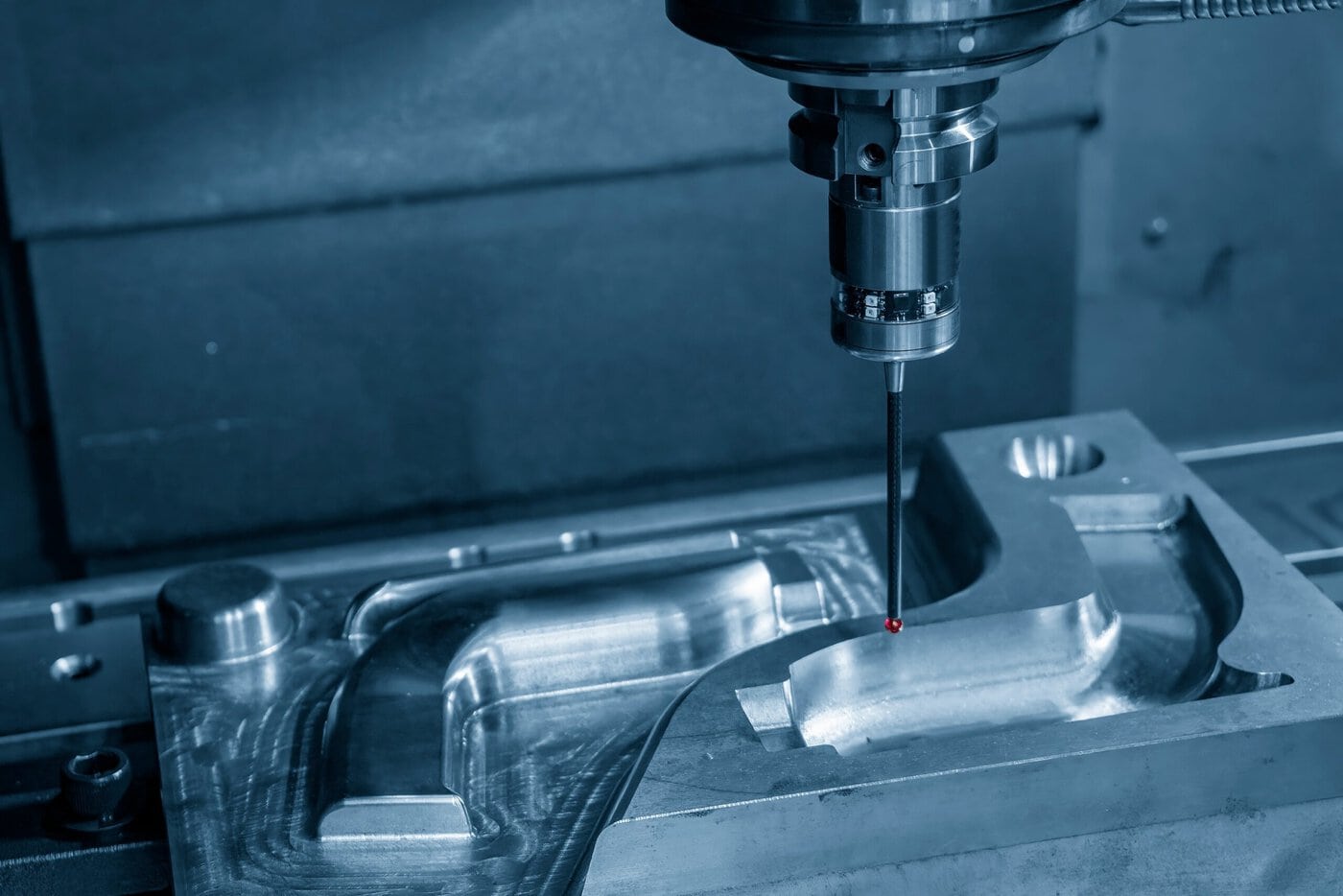

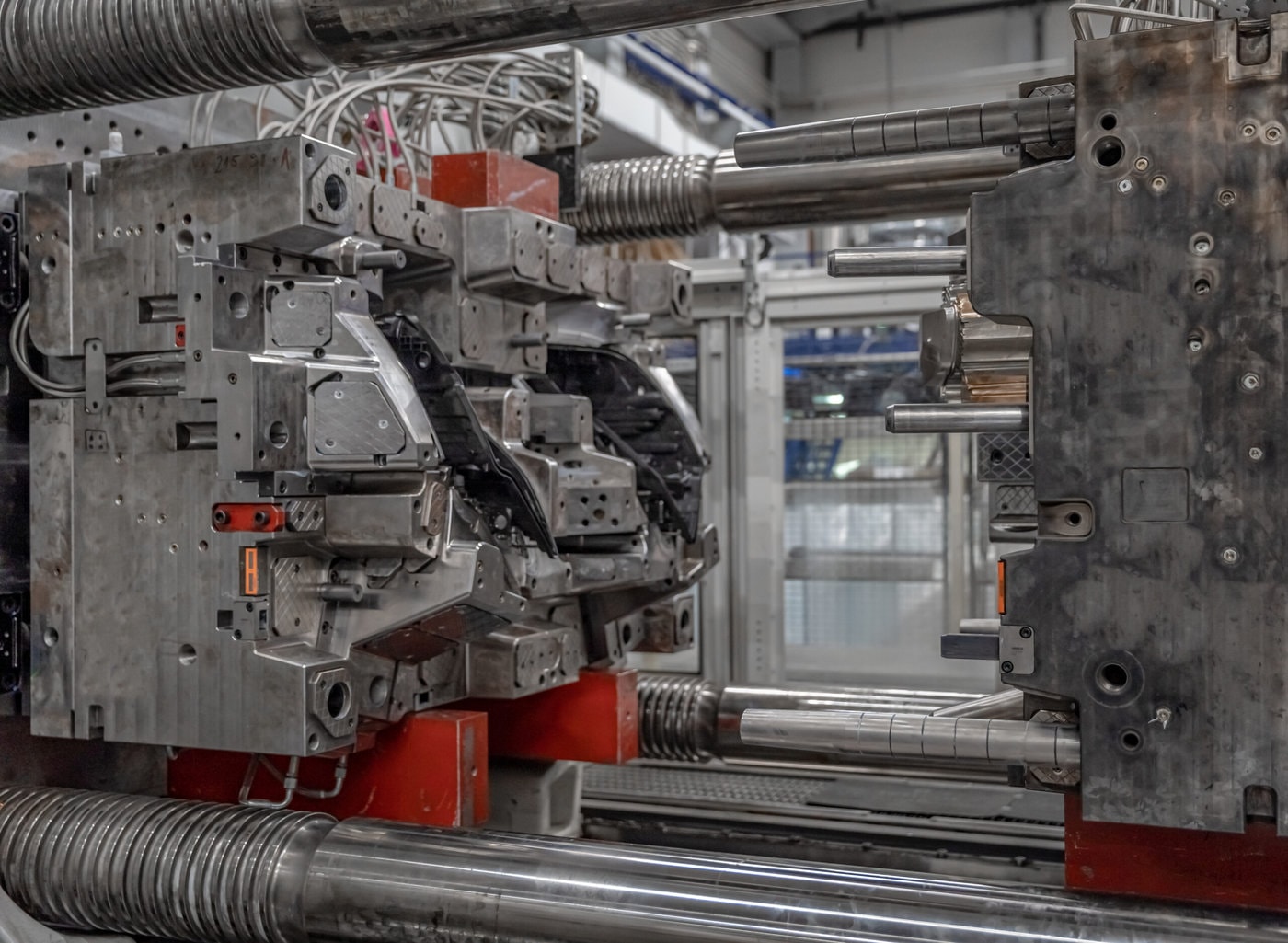

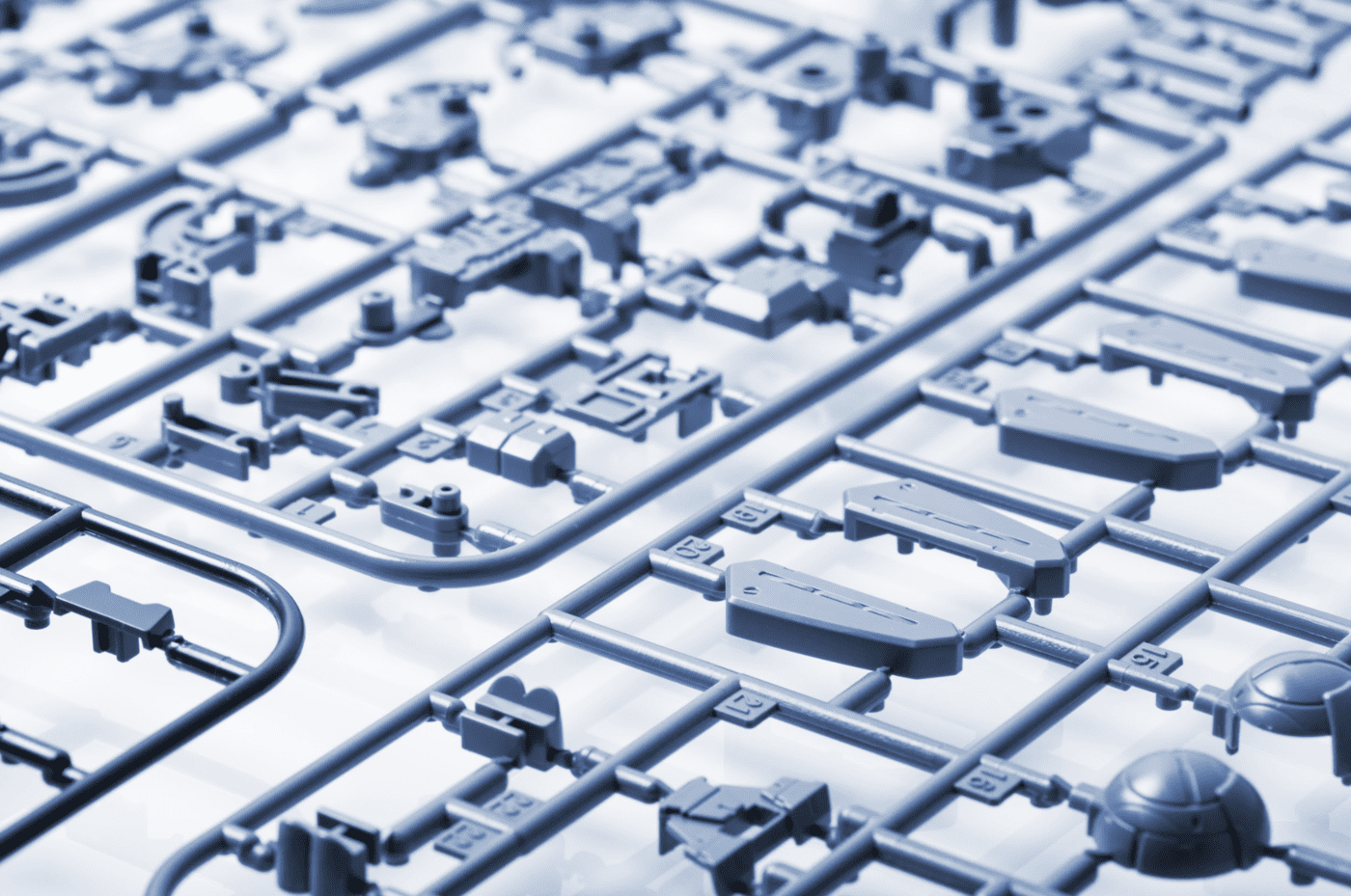

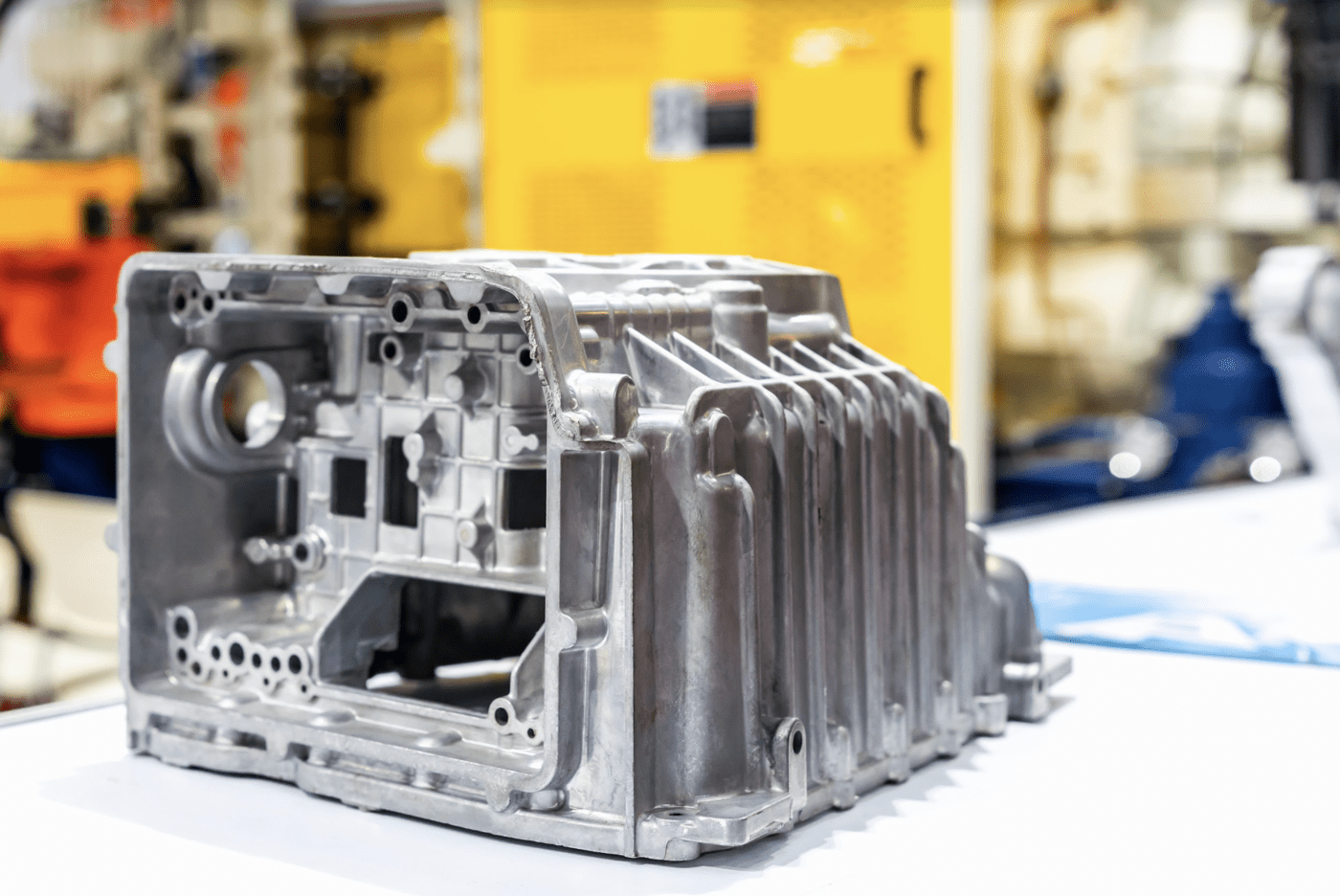

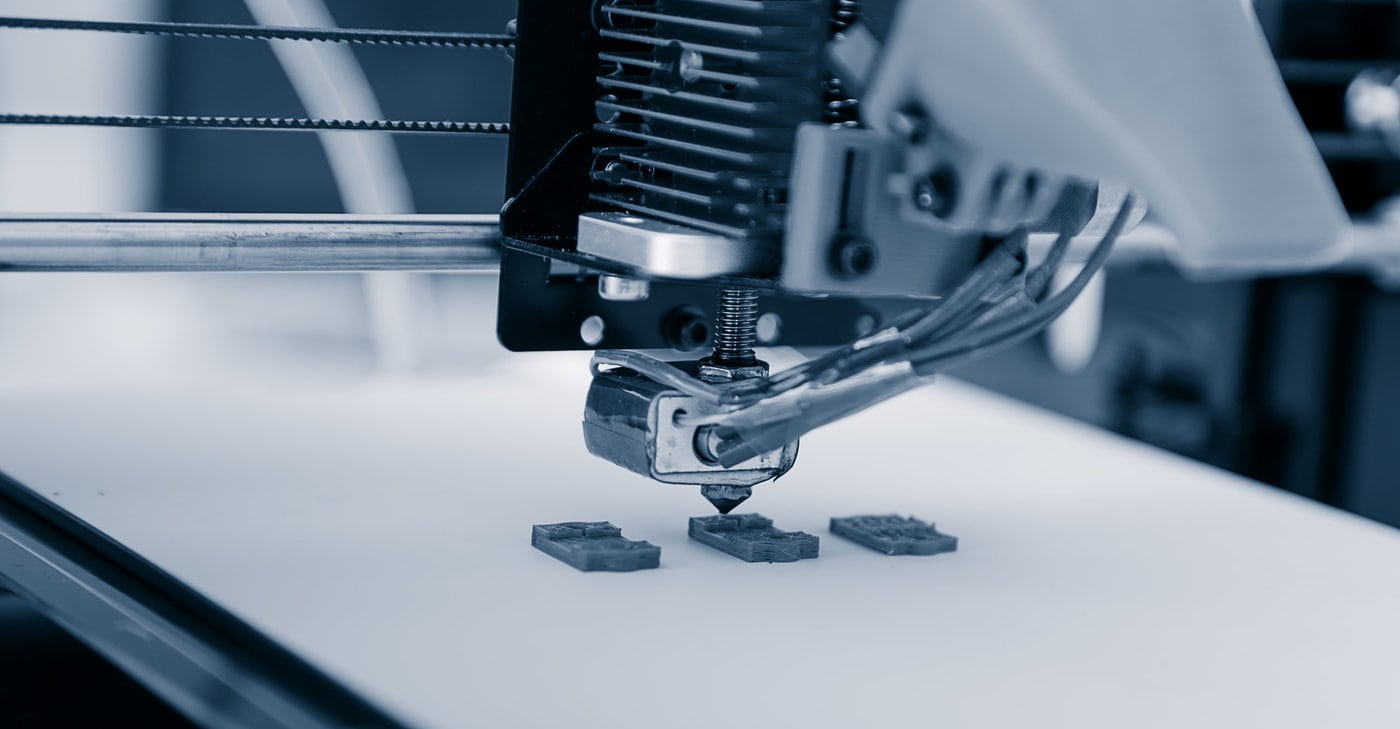

Intro Injection molding is a great way to quickly and affordably make millions of identical parts each year. However, there are a lot of ins and outs of running a high-quality injection molding operation. In this quick guide, you’ll learn all about injection molding. Our…