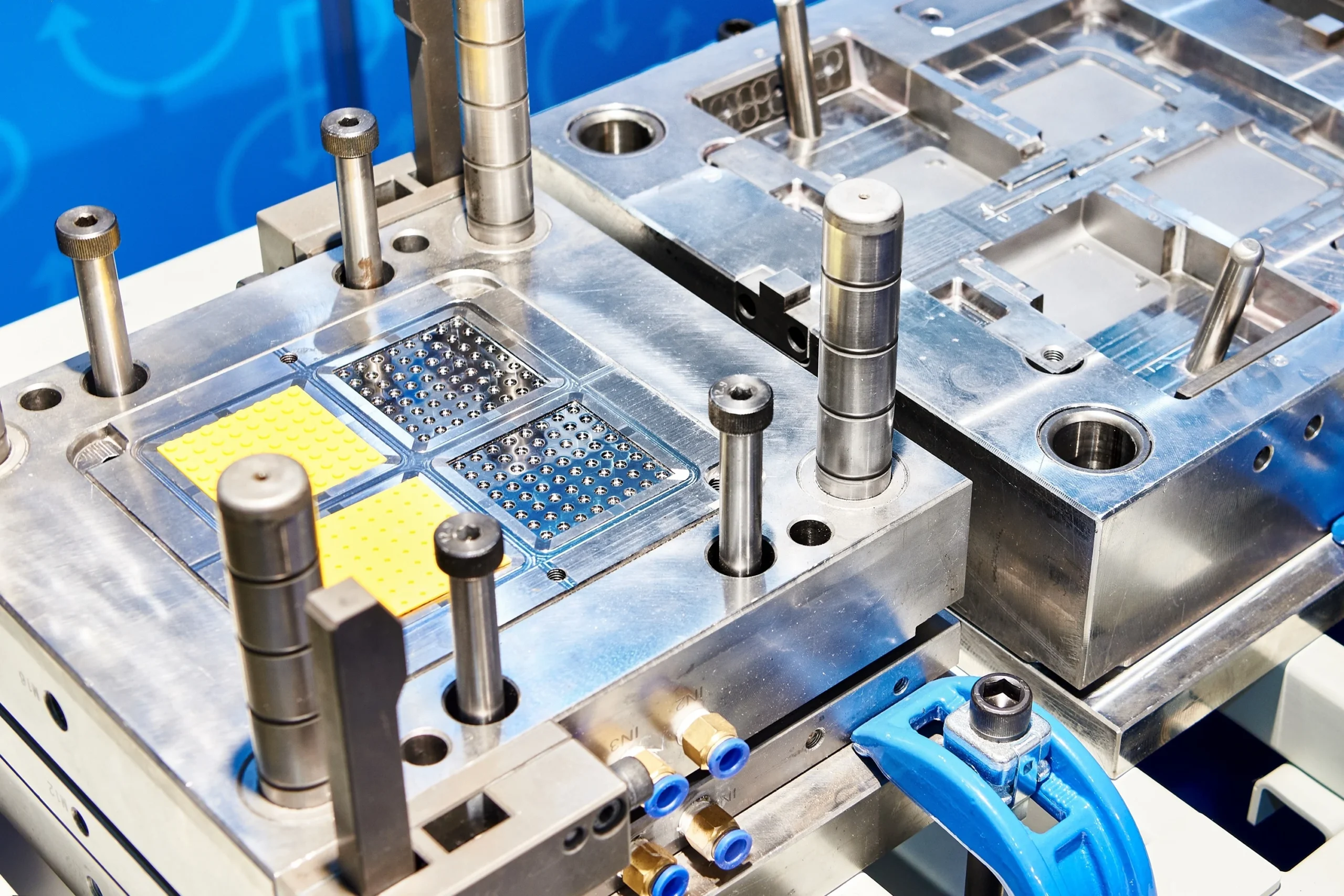

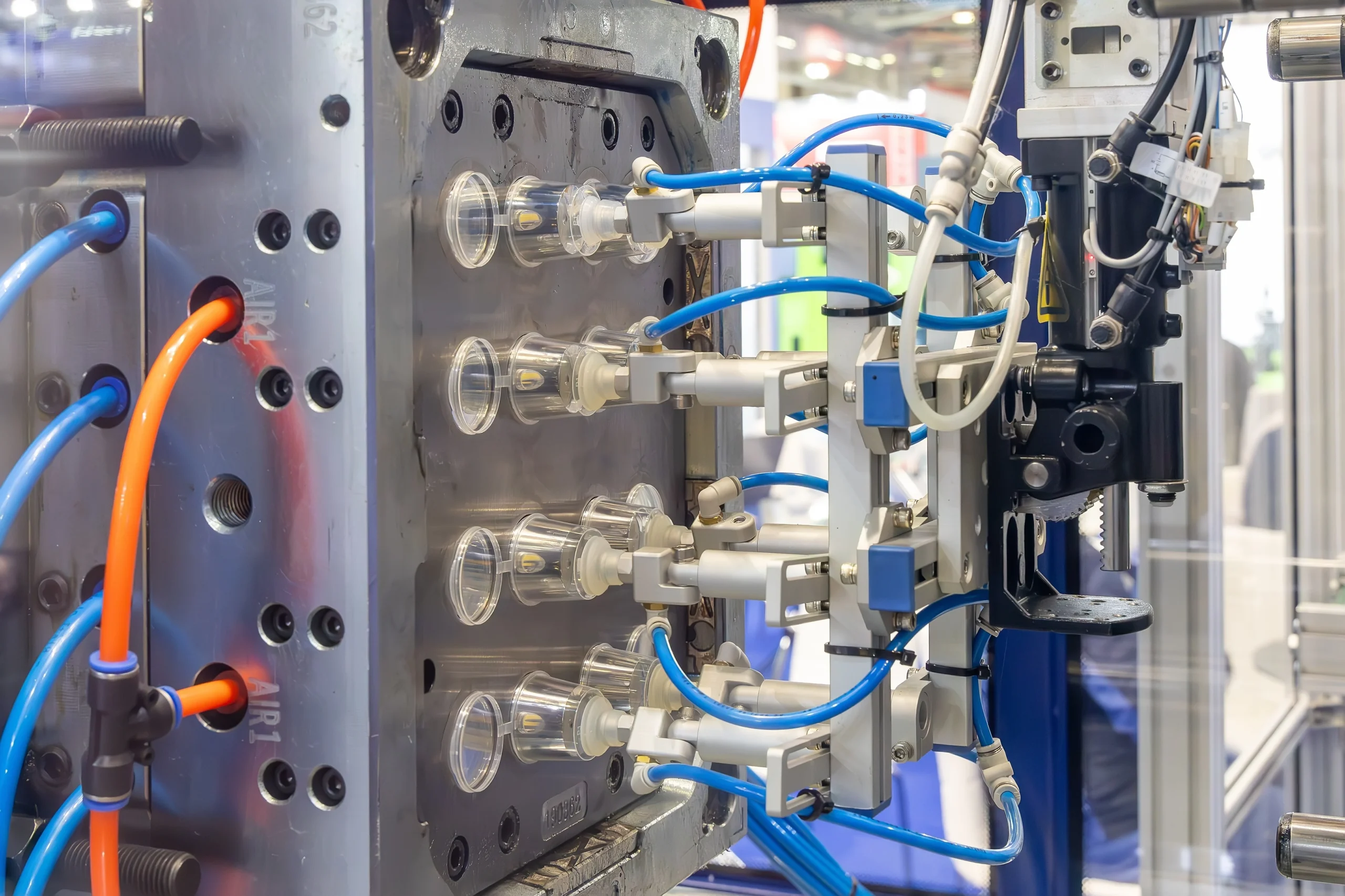

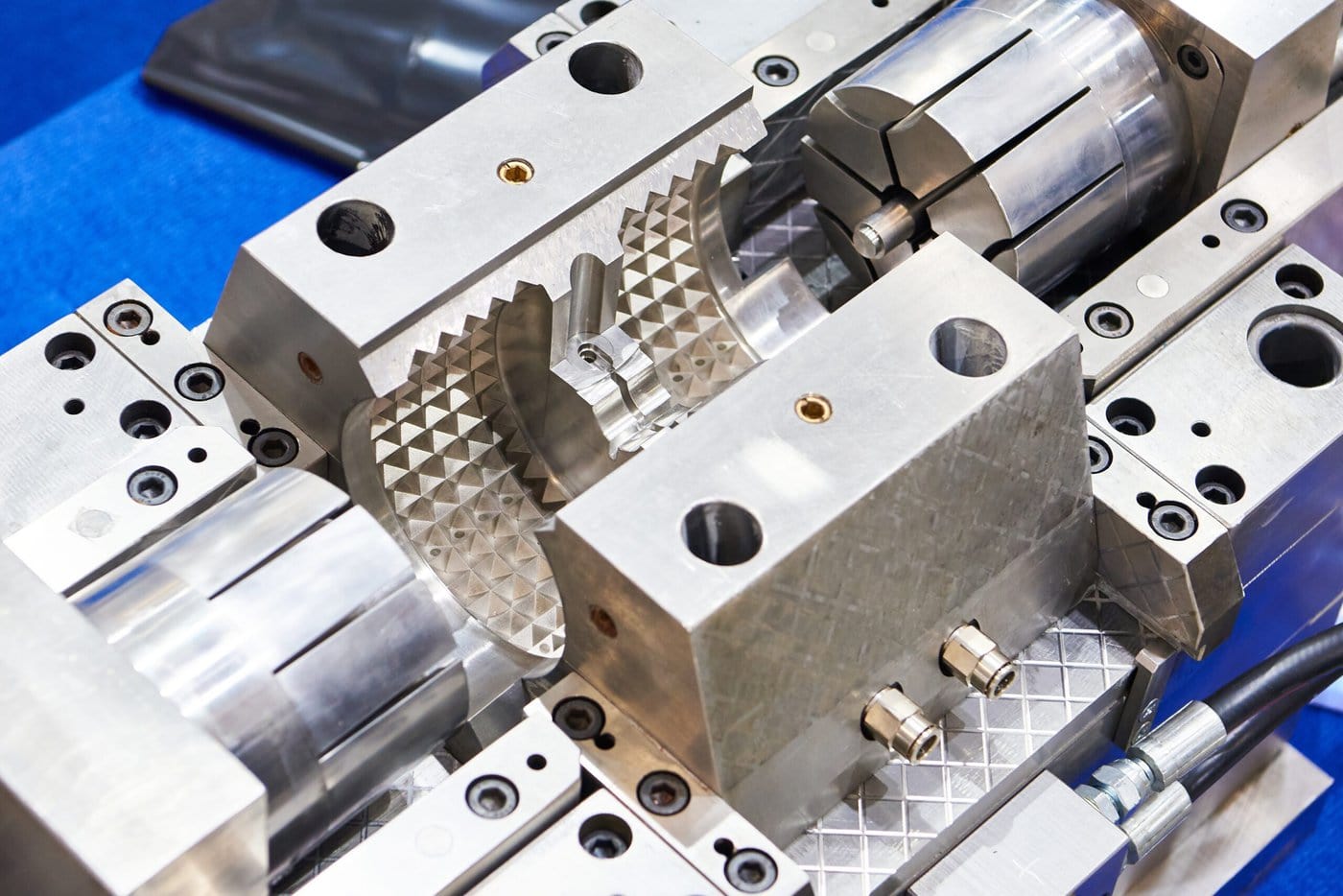

What Is a MUD Insert Injection Mold?

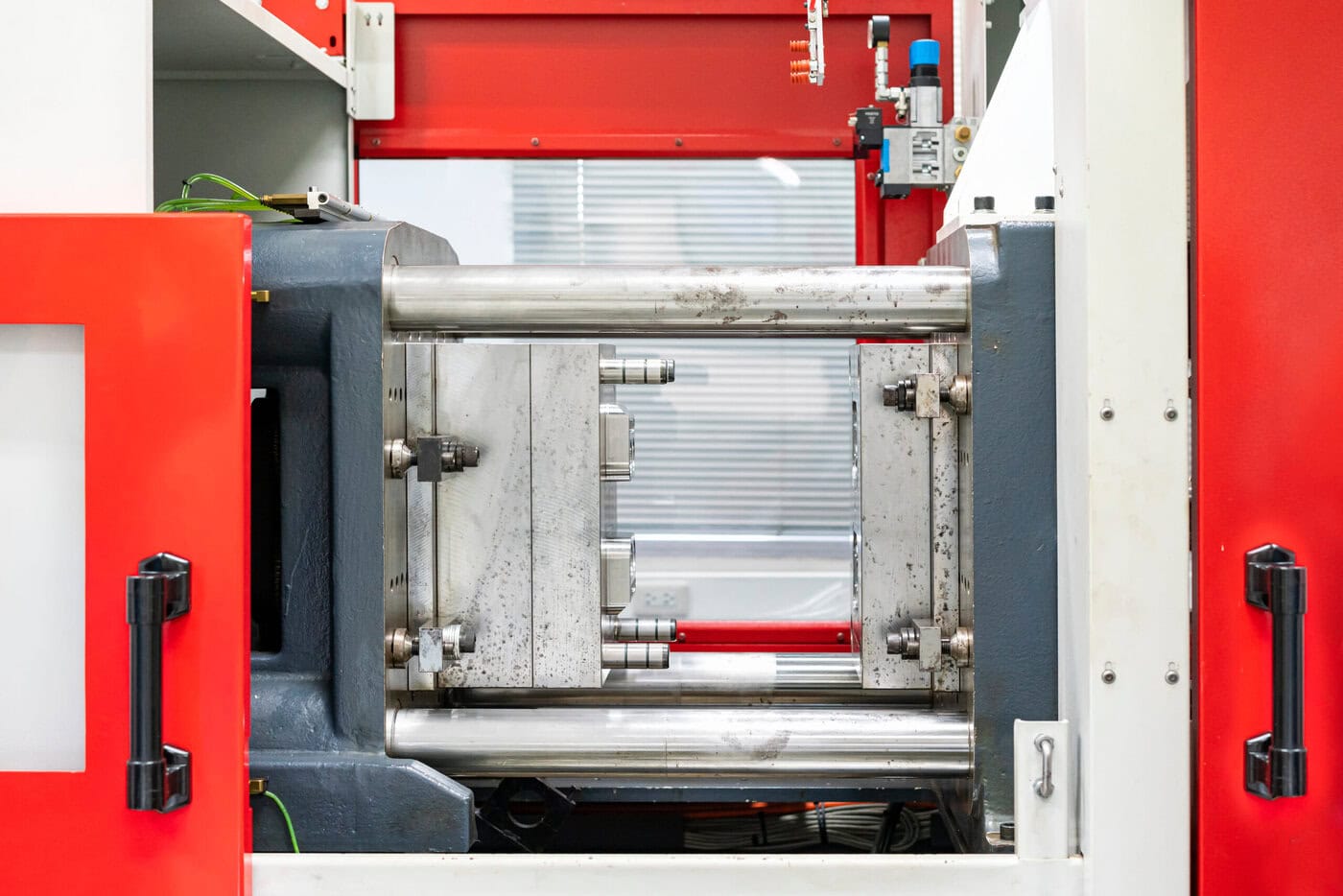

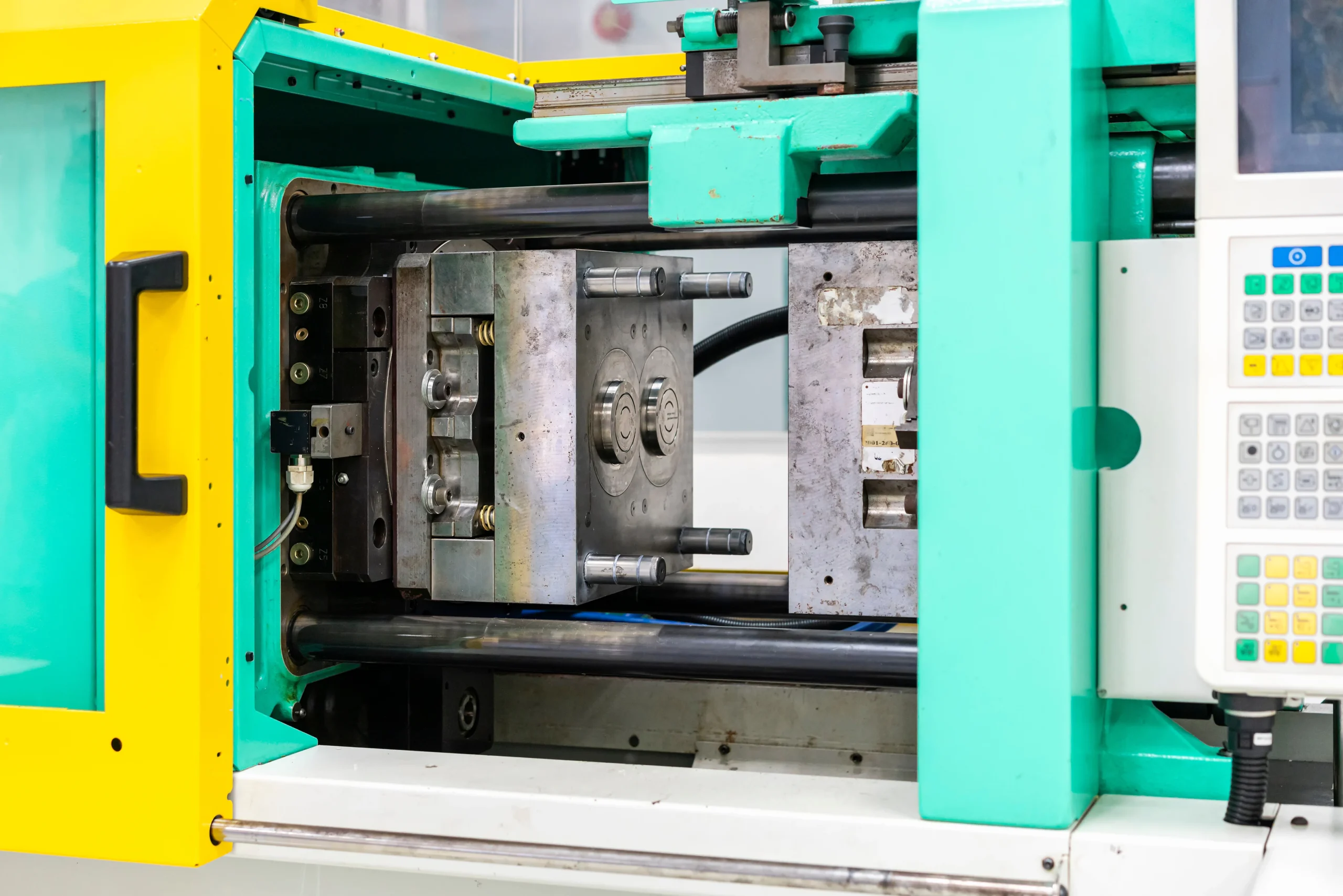

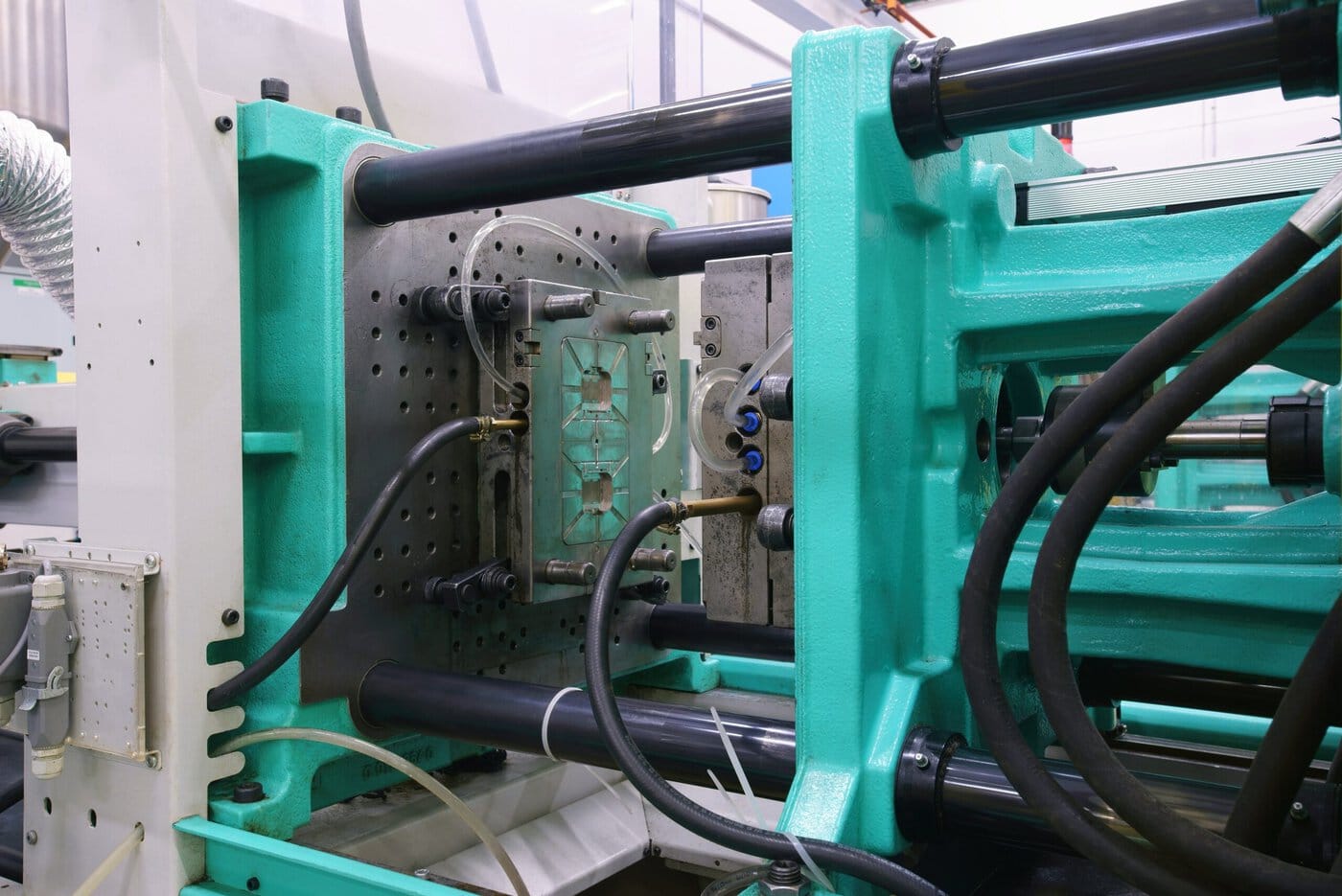

Injection molding is the go-to manufacturing method for creating high-quality, consistent parts in large quantities. Among the various techniques, MUD insert injection molding offers a unique and efficient approach, especially for low- to medium-volume production or rapid prototyping. For mechanical engineers and designers exploring cost-effective…