Aluminum Metal Treatments and Their Advantages

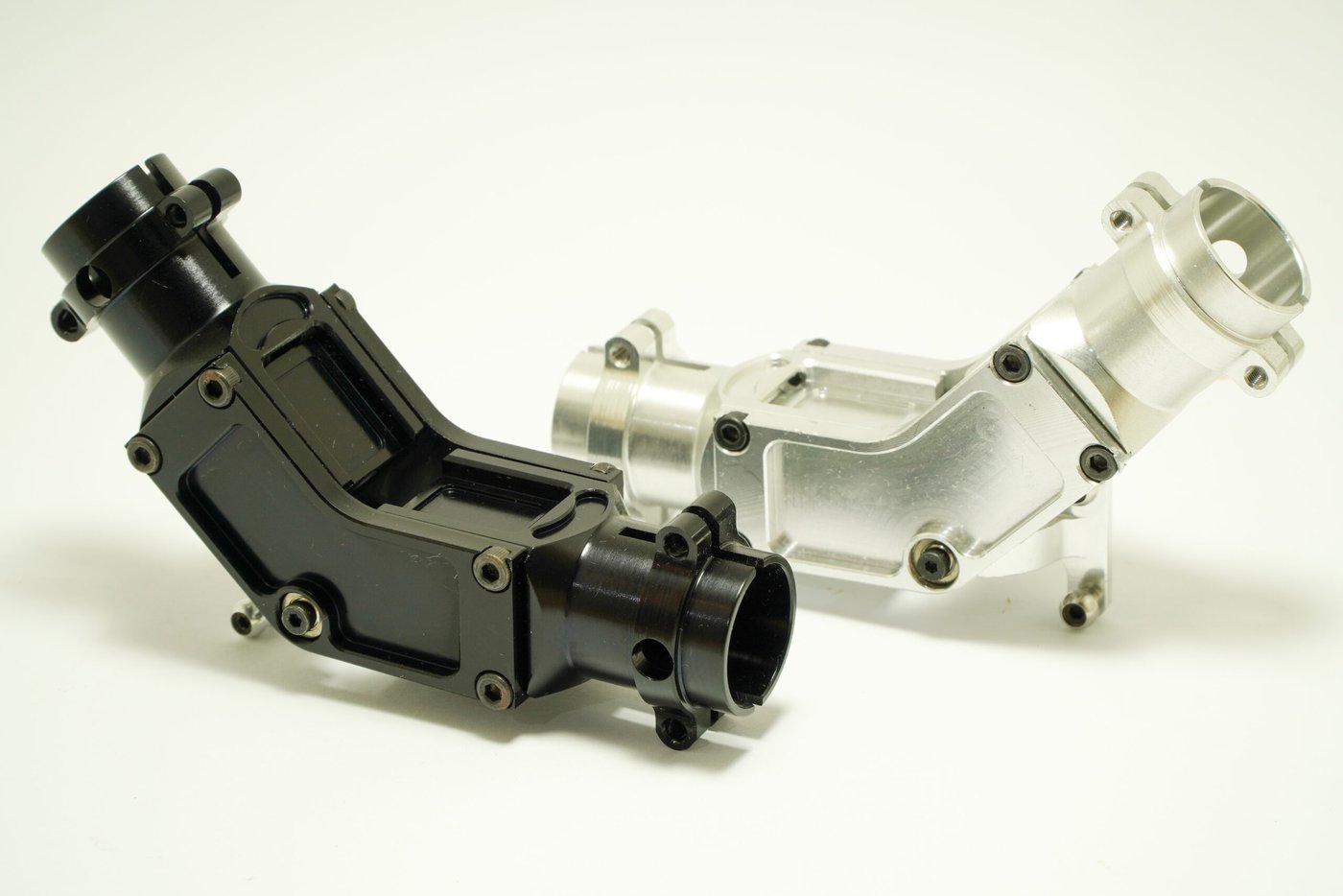

In our shop, aluminum is one of the most common materials used across industries and applications. It is lightweight, corrosion-resistant, easy to work with, and relatively inexpensive. If you want to take your aluminum parts to the next level, you can consider a finishing treatment…