Rapid Axis for Stamping and Die Cutting

Rapid Axis provides competitively priced, quality parts; quickly. With capabilities in stamping and die cut tooling, Rapid Axis can be your source for prototype, short-run or production flat pattern part requirements ranging in quantity requirements as low as twenty parts and spanning up to one million or more. We cut common materials including transfer tape, aluminum sheet stock, shim stock and plastic or rubber sheeting.

Why Rapid Axis is the best choice for Stamping and Die Cutting:

With a variety of presses and cutting tooling at our disposal, Rapid Axis can process a variety of parts from simple transfer tape inserts, to gaskets to flat sheet enclosure components. With precision inherent in the process you can get great repeatability with stamping or die cutting and at a fraction of the cost for other processes. With experience in running a variety of materials and excellent technical oversight on projects, Rapid Axis is the best choice for any projects within Stamping or Die Cutting.

High repeatability

Precision components

Wide variety of materials

What are Stamping and Die Cutting?

When we explain stamping and die cutting to different businesses, we often use cookie cutters as an example. The cutter is an example of a stamper or die. You use the cookie cutter to take out a section of cookie dough that resembles a certain shape.

This same concept is used in the manufacturing world. If you swap out the cookie dough for a web of thin material and sharpen the cookie cutter, you effectively have a stamping and die-cutting operation.

People will use a stamp to remove pieces of a web of material. Typically, it’s used on paper, fabric, leather, or sheet metal. This method allows you to create a number of identical parts easily. These parts could be used as part of an assembly or sold directly to customers.

Die cutting or stamping tools need to be made of strong material and carefully fabricated. If there is a slight mistake in the tool, then all of the products you stamp out will be defective. This only wastes your time and money and can lead to a big production issue.

It’s also important that the cutters used are sharp enough to cut through your material web. If you’re stamping out sheet metal, a dull insert can damage your products and result in a messy cut. This is why so many people choose Rapid Axis for their tooling — we offer high-quality parts at affordable prices.

Stamping and Die Cutting Applications

We understand that our stamping and die-cutting offering is pretty broad. Here are some specific applications and benefits to describe what you can achieve when you choose Rapid Axis for stamping and die cutting.

Quickly Create Parts from a Sheet

If you have a sheet of material, the quickest way to make your part is with a stamp. The metal stamp will get punched into your sheet of material, and you’re left with a perfectly-shaped product. There are no other manufacturing options that can achieve the same results and take the same amount of time.

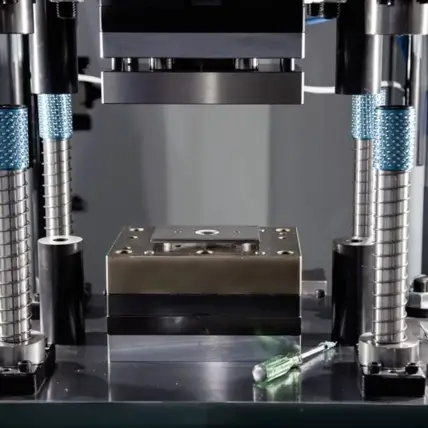

The throughput can vary wildly from one application to the next. Rapid Axis primarily utilizes stamping by hydraulic press which allows for great repeatability though we can process small batches of components it’s not uncommon for order sizes within the thousands to come through our shop.

Make High-Strength Parts

One benefit of using a stamp or die-cutting operation is that the final product can be very strong. There are certain manufacturing methods that can weaken the raw material while it’s being worked. With stamping, that’s not the case.

It’s also important to mention that the pieces will be a single, solid piece of material. If you look at the physics of the part, this part would be stronger than a part that was welded, fused, or bent.

Fabricate High-Volume Parts Out of Metal

Putting together a large order of identical parts made out of metal is pretty difficult. Die Cutting typically is an economic and relatively quick solution to this. With this option, you can load your die into an automated machine and allow it to cut out parts from a metal sheet all day long.

While there are plenty of examples to consider, a computer tower might be easy to visualize. The six faces that come together to make the case are most likely made out of die-cut pieces of sheet metal.

A single machine can easily cut out all six of these pieces in a matter of seconds. Doing the same operation on a CNC machine might take hours for a single assembly. The other difference is that a die-cutting machine might require very little human interaction. A CNC machine needs an operator to always be present and oversee the operation.

When you combine these factors, you’re left with a metal fabrication method that can produce hundreds of thousands of units a year — a level of production that you won’t find in other sheet metal operations.

Works With Multiple Material Options

Stamping and die cutting can be done on a wide variety of different materials. We mentioned a handful of options earlier, but there are actually hundreds of different materials you can use this process on.

This means that you can easily create products for your operation, regardless of the material used. The more important factor is the thickness and strength of the material you’re using it on.

Since this technique is so process-dependent, you might benefit from talking to one of our experts at Rapid Axis. After understanding your operation, we can recommend the right manufacturing technique for you. If it falls into the world of stamping and die cutting, we’ll help you execute the process and handle all of the machining required.