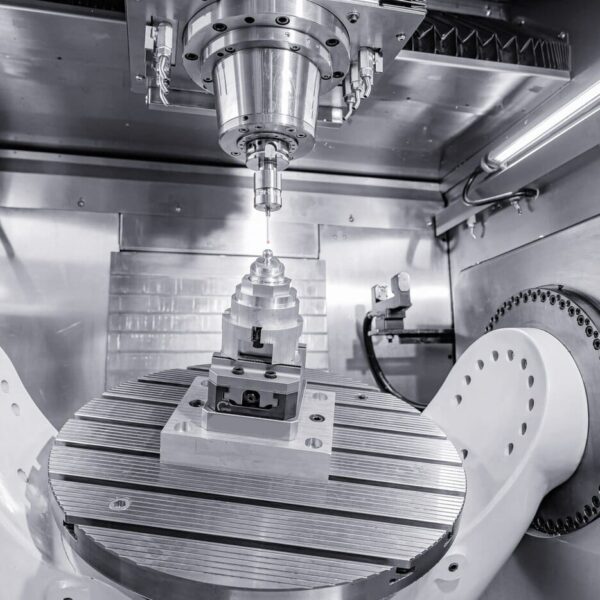

Rapid Axis for Titanium CNC Machining Services

As a full-service machine shop, we’ve worked on a ton of projects that involved titanium machining. Our titanium CNC machining services are high-quality, offer fast turnarounds, and leave you with production-ready parts.

Why Choose Rapid Axis for Titanium CNC Parts?

Titanium has great thermal, mechanical, and chemical characteristics, and is often viewed as a “premium” material. As you might know, it also has one of the better strength-to-weight ratios when it comes to consumer-level materials, so it’s a top choice for industries like defense, aerospace, automotive, and medical.

With our help, you can get high-quality CNC titanium parts with your desired finish in a fraction of the time. Our additional quality control steps will help reduce errors and ensure you don’t receive parts that are out of spec.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

Titanium comes in a few different alloys, called “grades”. Each titanium grade has a combination of features that makes it a more desirable material option over its counterparts:

Grade 2 (Commercially Pure Titanium)

Grade 2 Ti has great corrosion resistance, weldability, machinability, and is great for general use.

Grade 5 (Ti-6Al-4V)

Grade 5 is the most common alloy that we use. It has great strength, it’s lightweight, and has high corrosion-resistance. Plus, it’s easier to source and work with.

Grade 23 (Ti-6Al-4V ELI)

Grade 23 is a more pure version of Grade 5, and it has even better biocompatibility and fracture toughness. We typically see this alloy used for surgical implants.

Grade 9 (Ti-3Al-2.5V)

Grade 9 Titanium is typically reserved for tubing and sheet metal applications. It has better formability while boasting great strength.

Finishing Options

Like any other metal, we also offer a range of finishing options for your CNC titanium parts. Finishing processes will change the functionality, look, and durability of your titanium machined parts. With us, you can choose from a number of finishing options:

Anodizing

Anodizing is a quick way to add even more corrosion resistance to your titanium parts. You can also opt for colored anodization which can make the finished part look better, too.

Bead Blasting

Bead blasting involves hitting the part with tiny pellets to remove tiny surface-level defects. The final product is more uniform and boasts a matte surface finish. It can help with corrosion-resistance while hiding surface imperfections.

Powder Coating

Our powder coating operation includes adding a durable protective layer to your titanium parts, then baking the part to bond the layer to your parts. Powder coating can be done in a number of colors and levels of sheen, so you can hand-pick how your CNC titanium parts will look.

Polishing

We can also polish your titanium machined parts into a mirror-like or stain finish. This is often chosen to make parts more aesthetically pleasing or hygienic.

Key Features of Titanium

There are a lot of great reasons to use titanium in your project:

- Incredible strength-to-weight ratio. As it stands, titanium boasts one of the best strength-to-weight ratios out of any material that you can find in a general machine shop. In other words, it has high yield and tensile strength while having a low density — in most loading scenarios, titanium is as strong as steel but about 45% lighter.

- Very high corrosion resistance. Titanium can be exposed to seawater and chemicals without rusting, allowing it to thrive in harsh environments and maritime applications.

- Low thermal expansion. Even when you heat up and cool titanium, you’ll notice that your parts are dimensionally stable. This is a critical aspect of aerospace and precision engineering.

- Better fatigue and creep resistance. A titanium part can be used over and over again without failing, unlike other parts that have poor fatigue resistance. This translates to better longevity and durability.

- Non-toxic and biocompatible. Titanium is a superstar in medical applications, since it is non-toxic and generally biocompatible, so the human body accepts titanium better than other materials.

General Restrictions

While there are a lot of benefits of using titanium, there are still some general restrictions to be aware of.

- Tolerance Details. We offer tolerances of ±0.005 inches or tighter with 2D drawings for our CNC-machined titanium parts.

- Maximum Part Size. While we can machine titanium parts in a wide range of sizes, there are some limitations. For questions about part sizing and tolerances, give us a call.

- Surface Finish Options. We offer a range of finishing options to enhance both the functionality and aesthetics of titanium parts. Whether you need a high-shine polish, a uniform matte finish, or improved corrosion resistance, we have a solution.

Titanium CNC Machining Applications with Rapid Axis

Titanium isn’t as ubiquitous as stainless steel or aluminum, but you can find dozens of different applications in which titanium is the best material to use. In our experience, there are some common industries that heavily rely on titanium parts:

Aerospace

Aerospace companies love titanium because it’s lightweight, offers great heat resistance, and resists fatigue over time. You might see it used on landing gear parts, structural components, or external features that have to deal with temperature fluctuations.

Medical Devices and Implants

Due to its great biocompatibility, a lot of companies use titanium for orthopedic implants and surgical instruments.

Defense and Military

The defense industry leans on titanium to maximize the performance of their projects, especially in the design of different vehicles. Since it is so strong and lightweight, you can use titanium as armor plating on vehicles, or as high-precision weapon components.

Automotive

Automotive projects can also use a combination of titanium and carbon fiber to make their vehicles as lightweight as possible while still meeting structural requirements. It’s not as common in entry-level consumer vehicles, but you’ll see a ton of titanium in performance-focused vehicles.

Industrial

Some industrial equipment also needs to use titanium to deal with high temperature swings and harsh environments. We’ve seen it used in chemical processing equipment and different precision tooling used across industrial sites.