Rapid Axis for Stainless Steel CNC Machining Services

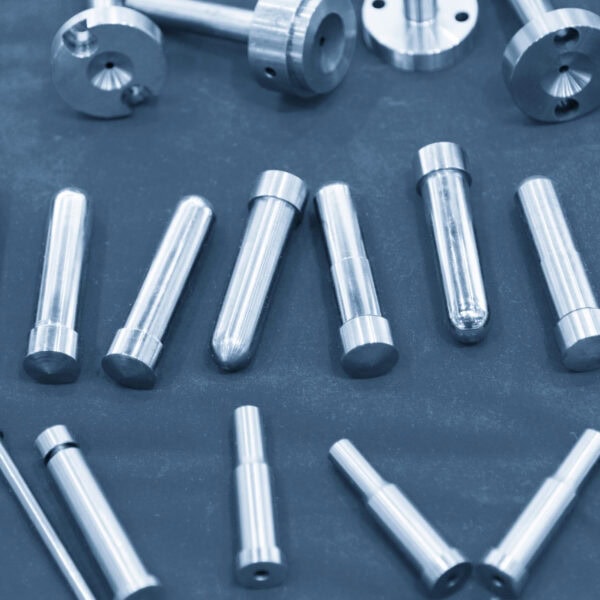

Stainless steel is one of the most common material options. It is a corrosion-resistant, strong, and easy-to-machine material that spans across industries and is used in many different applications. At Rapid Axis, we offer professional stainless steel CNC machining services that can help your company.

Why Choose Rapid Axis for Stainless Steel CNC Parts?

In our experience, stainless steel is one of the most common metals used across applications and industries. People have used our stainless steel CNC machining services to make anything from a simple bracket to a massive mounting plate for industrial equipment.

We take a lot of pride in our work, and we constantly go the extra mile to deliver parts that exceed your expectations. Since we first opened our machine shop, we’ve been getting compliments on our stainless steel CNC machining services from companies across the country. Our state-of-the-art fabrication shop hosts a number of multi-axis CNC milling machines, lathes, drill presses, and much more. Plus, we offer more finishing operations under one roof so you can save time and money on every project.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

Not all stainless steel products are the same, and there is actually a range of different alloys that you can choose from. Some of the more common options that make up our stainless steel CNC machining services are:

304 Stainless Steel

This is the most common alloy, and it has great corrosion resistance, good machinability, and is easy to source. 304 SS is a nice alloy to default to if your project doesn’t have extreme constraints.

316 Stainless Steel

This alloy adds more molybdenum which makes the alloy even more corrosion resistant. It’s a good choice for marine and chemical processing applications.

303 Stainless Steel

303 stainless adds more sulfur which makes the alloy easier to machine, form, and work with in the machine shop. You might choose 303 if you need high-precision and intricate features in your parts.

17-4 PH Stainless Steel

Precipitation-hardened stainless steel has higher strength and corrosion resistance, and we’ll typically use this alloy for defense and aerospace projects.

410 Stainless Steel

You’ll often see fasteners and mechanical components made out of 410 SS since it can be heat-treated and comes with really impressive wear resistance. It’s perfect for parts that need to be threaded and unthreaded routinely.

Finishing Options

In addition to our impressive stainless steel CNC machining services, we also offer a whole host of finishing options. These will take your parts to the next level, adding even more functionality and better aesthetics to each part.

Passivation

Passivation removes the free iron from the surfaces of your parts, which makes it even more corrosion-resistant. It’s a quick way to make your parts last longer, especially in unfavorable environments.

Polishing

A simple polish makes stainless steel parts smoother, enhancing every part’s shine and making things look more professional.

Bead Blasting

Bead blasting does the opposite of polishing, and it actually dulls the surface, creating a uniform matte finish on your stainless steel parts. This is another aesthetic improvement and can be used when you want non-reflective surfaces.

Electropolishing

Electropolishing is the process of removing tiny microscopic imperfections on the surface of your stainless steel parts. This makes every part even easier to clean and boosts the corrosion resistance since there is a lower risk of pitting.

Powder Coating

Finally, we can powder coat any stainless steel parts. This is a powder that gets sprayed onto your part’s surfaces and bakes onto your parts, adding more durability and giving you free reign when it comes to the color and finish of your parts.

Key Features of Stainless Steel

In any industry, you can find countless examples of stainless steel parts, and there are plenty of good reasons to use this metal:

- Corrosion resistance. The “stainless” part of the name refers to stainless steel’s corrosion resistance. The right alloy can be used in acidic and high-moisture environments without any risk of corrosion, even long-term.

- High tensile strength. Stainless steel is one of the strongest consumer-grade materials that you’ll find. Its tensile strength is about three times higher than aluminum, on average. There’s a reason why massive warehouses use stainless steel beams to support the structure.

- Hygienic properties. Stainless steel is also non-porous, which means it can be cleaned easily. This makes SS a good choice for cleanrooms, medical environments, or anywhere where food is handled.

- Heat resistance. Certain stainless steel grades can handle really high temperatures that you might find in specialty industrial applications, like the shell of a boiler.

- Versatile aesthetic appeal. With a naturally sleek, modern look, stainless steel is often used in commercial and consumer applications where appearance matters. It can also be polished, brushed, or coated to achieve different finishes.

- Ease of manufacturing. Stainless steel is highly machinable, offering excellent dimensional stability and precision. It can be milled, turned, and drilled with tight tolerances, making it ideal for complex parts.

General Restrictions

While there are a lot of benefits of using stainless steel, there are still some general restrictions to be aware of.

- Tolerance Details. We offer tolerances of ±0.005 inches or tighter with 2D drawings for our CNC-machined stainless steel parts.

- Maximum Part Size. While we can machine stainless steel parts in a wide range of sizes, there are some limitations. For questions about part sizing and tolerances, give us a call.

- Surface Finish Options. We offer a range of finishing options to enhance both the functionality and aesthetics of stainless steel parts. Whether you need a high-shine polish, a uniform matte finish, or improved corrosion resistance, we have a solution.

Stainless Steel CNC Machining Applications with Rapid Axis

Stainless steel is a universal material, and it’s used in a lot of different industries and applications. Here are some of the more common examples:

Automotive Industry

Automotive companies use our stainless steel CNC machining services so they can create durable, temperature-resistant parts. Anything from an exhaust system to structural brackets and fuel injection components can use stainless steel to get the best results.

Since this metal is strong, you don’t have to worry about parts cracking and failing as often as you do with aluminum parts.

Energy and Power Industries

The energy sector saw a big boom in using stainless steel, especially as new sustainable energies are being implemented. With wind turbines, just about every part of the assembly uses stainless steel. Solar plants use stainless steel CNC machining services to create heat exchangers, backing plates, and structural members.

In the nuclear and oil industries, pipeline components are made out of stainless steel for its non-reactive properties and ability to span long distances without failing.

Medical and Pharmaceutical Industry

Medical companies rely heavily on stainless steel since it can be used in cleanrooms and surgical applications. Since stainless steel can be cleaned, you might find it used in surgical instruments, medical device housings, and even in implants. Biocompatibility makes certain stainless steel alloys a go-to for implants.

Aerospace and Defense Industries

The aerospace and defense industries prefer to use stainless steel since it’s easy to manufacture, incredibly strong, and durable. Our customized stainless steel CNC machining services can make aircraft engine components, landing gear parts, and entire military-grade vehicles and equipment.

Food Processing and Consumer Goods Industries

The final industries to look at are the food processing and consumer goods industries. Both of these need to manufacture consumer-grade products at massive scales with great reliability. They often choose stainless steel for a variety of equipment, consumer appliances, and kitchen appliances to prepare the food.

This is another scenario where stainless steel is preferred because it can be cleaned easily and can last a long time without rusting.