Rapid Axis for Polycarbonate CNC Machining Services

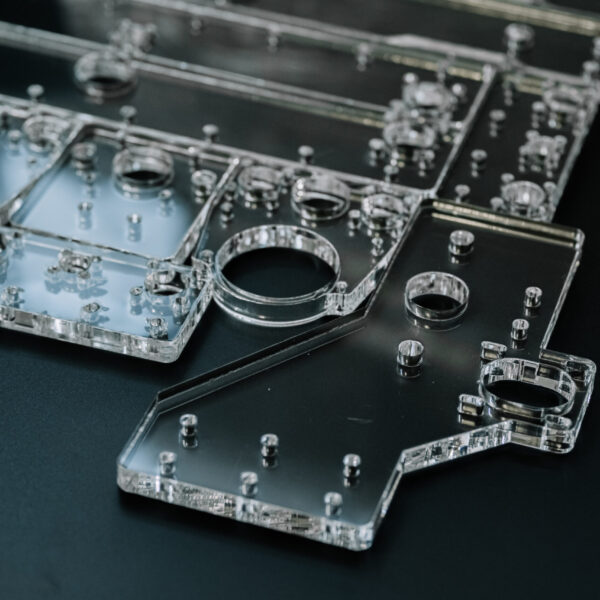

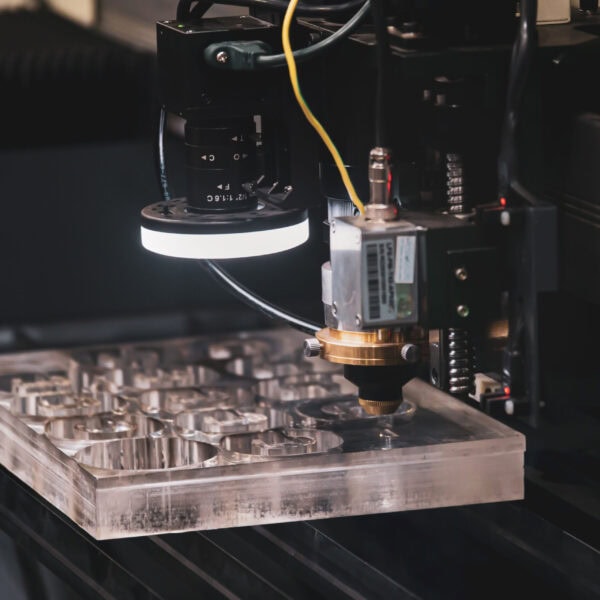

At Rapid Axis, we provide comprehensive polycarbonate CNC machining services, finishing options, and more. Our cutting-edge CNC equipment and technical expertise enable us to deliver exceptional polycarbonate parts while reducing costs and lead times. From individual prototype parts to large production runs, our team is equipped to support your polycarbonate needs.

Why Choose Rapid Axis for Polycarbonate CNC Parts?

Polycarbonate is an incredibly versatile and high-performing material. It’s a thermoplastic that’s renowned for its combination of strength, thermal stability, and optical clarity. In other words, it’s a see-through plastic that is incredibly strong and handles high temperatures well.

Our team at Rapid Axis has experience working with polycarbonate since the first day our doors opened. Our polycarbonate CNC machining services are fully customizable to meet the needs of your operation. Whether you need a single part, or a thousand massive parts made out of polycarbonate, we’re here to help. We can handle all of the machining and finishing steps for you.

We do more under one roof so you can save time and money on each project.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

When it comes to choosing the right polycarbonate, there are a few options to choose between. Generally speaking, all of these are almost the same, with just some minor differences, so you can’t go wrong with your final choice. As always, reach out to us if you have specific questions about material choice:

Clear polycarbonate

These sheets are typically thinner and more focused on optical transparency, making the plastic even more see-through.

Bulletproof polycarbonate

An option that comes in thicker choices, added lamination layers, and boasts “bullet-resistance”.

Anti-static polycarbonate

In applications where flammability or shock risks need to be mitigated, anti-static polycarbonate can be used. It is electro-static dissipative, which prevents build-up and shock risk.

Mirrored polycarbonate

This material adds a reflective film that can either be a normal mirror or a two-way mirror, which is often used in police investigation rooms.

Abrasion-resistant polycarbonate

By default, these sheets have an additional scratch-resistant coating on each side that makes your polycarbonate even more resilient against abrasion.

Tinted or colored polycarbonate

Finally, they also make polycarbonate sheets that come with a tint or a slight hue of a different color. This material is typically used for aesthetic purposes.

Finishing Options

We take our polycarbonate CNC machining services a step further by also including a number of finishing steps to choose from. These processes are done after the part is fully machined, but before we ship it to your facility.

Vapor Polishing

With any of our plastics CNC machining services, we offer vapor polishing which smooths out your parts and makes them look more professional. With polycarbonate in particular, vapor polishing can also make parts much more transparent.

Scratch-Resistant Coating

To improve the aesthetics and extend the durability of your parts, you might choose a scratch-resistant coating. Polycarbonate is naturally resistant to shattering and chipping, but it’s prone to scratch easily, so this coating can help a ton.

Bead Blasting

We can also use fine, soft plastic media at a low pressure to bead blast your polycarbonate parts. This creates a more opaque and smoky look to your parts, so it’s reserved for applications where optical clarity isn’t required. But it’s a cool way to change the aesthetics of your parts and get rid of unwanted glare or reflections.

Custom Painting and Branding

As always, we offer custom painting and branding finishing steps. This boosts the aesthetics of your parts and allows you to customize or mark different equipment with ease.

Key Features of Polycarbonate

In general, people like to use polycarbonate because of some major selling points:

- Good dimensional stability. Polycarbonate does a good job of resisting warping and shrinkage, and sheets of polycarbonate are easier to machine than other plastics. This gives you more design freedom.

- Great optical clarity. A stock piece of polycarbonate is completely see-through. Even after machining, the right finishing steps can make your pieces have near-glass clarity. In settings where you need to protect yourself but still see what’s going on inside of a machine or process, polycarbonate should be your go-to.

- It’s shatter resistant. Polycarbonate is shatter, chip, and impact-resistant. A thick enough piece can even stop a bullet, which is why polycarb is often used when applications call for bulletproof glass.

- Withstands high temperatures. We’ve fabbed parts out of polycarbonate for plenty of applications that deal with high temperatures and nasty environments. Every time, polycarbonate has stood up to the challenge and succeeded, thanks to its inherent strength and heat resistance.

- Very lightweight. It’s also worth noting that polycarb is significantly lighter than glass, but provides a lot of the same benefits (plus a lot more).

General Restrictions

Alongside all the great parts of polycarbonate, there are a few restrictions that we should also mention.

- Tolerance Details. We offer tolerances of ±0.005 inches or tighter with 2D drawings for our CNC-machined polycarbonate parts.

- Maximum Part Size. While we can machine polycarbonate parts in a wide range of sizes, there are still some limitations. Contact us with your project requirements, and we’ll let you know if we can accommodate your size and tolerancing needs.

- Surface Finish Options. Secondary finishing steps are often required to get full transparency and smoothness for polycarbonate parts, so we offer a full suite of surface finish services.

Polycarbonate CNC Machining Applications with Rapid Axis

As you just learned, polycarbonate is strong, see-through, durable, and shatter-proof. As a result, it is used across industries and in too many applications to count. Here are a few common applications that might apply to you:

Automotive

The automotive industry uses polycarbonate CNC machining services for instrument panels, protective covers, and headlight lenses. Anywhere that a part needs to be strong and see-through, it’s likely polycarbonate, with the exception of the windshield and windows.

Polycarbonate is also a great choice since it’s lightweight and hardworking, so automotive companies can do more with the same material.

When you’re making a vehicle that needs incredible strength or much lower weight, like a vehicle for transporting the president or a Formula 1 vehicle, polycarbonate is the most common option. Fun fact: polycarbonate is used instead of glass for windows and windshields in these applications since it’s bulletproof and lighter than real glass.

Industrial Equipment and Safety

In the industrial world, polycarbonate is the go-to choice for any protective shielding and plastic guards. Whenever you see an access window or viewing pane, you can bet money that it’s polycarbonate. This material is preferred since it’s so strong, durable, impact-resistant, heat-resistant, cost-effective, and completely see-through. It allows you to see the inside of dangerous equipment without any fear.

Specifically speaking, you might use polycarbonate to make transparent machine guards, safety windows, electronics enclosures, and OSHA-compliant shields.

Medical and Scientific Equipment

Medical companies prefer to use polycarbonate when they need a transparent part that doesn’t react to a lot of different chemicals. As a result, you’ll spot polycarb used for device housings, optical lenses, and sterile barriers that are used during observation.

For scientific equipment, the same material is used across the board when plastic parts have to be strong and transparent.

Consumer Electronics

Consumer electronics use polycarbonate CNC machining services typically for the durability and transparency of PC. You might find it used on LED covers, touchscreen panels, and an assortment of transparent casings.

Polycarbonate is typically less expensive and easier to manufacture custom parts with as opposed to glass, so your prototyping and production runs will be simplified with this thermoplastic.

Aerospace and Defense

Polycarbonate is one of the most common plastics you’ll find on any aerospace or defense project. Windows, helmet visors, and protective shields will use polycarbonate since it can take a huge impact without shattering, it’s lightweight, and you can see through the plastic.

Within these two industries, you can almost guarantee that any transparent part is made out of polycarbonate, that’s how common it is. It should show you how impressive polycarbonate really is: it’s used to save lives in two of the more dangerous industries.