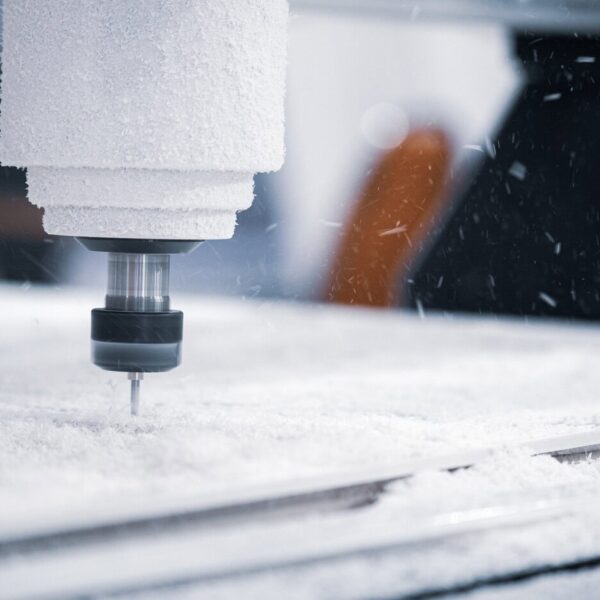

Rapid Axis for Plastic CNC Machining Services

Plastic parts have a nice balance of machinability, strength, versatility, and affordability — this makes them a great alternative to metals in a lot of engineering applications. Within the umbrella, there are so many different types of plastics that have their own strengths and weaknesses. With our help, you can find the perfect plastic for your next project and start receiving high-quality parts.

Why Choose Rapid Axis for Plastic CNC Parts?

In our machine shop, you can choose from either metal or plastic CNC machining services. Our plastic CNC machining services include dozens of different plastic and plastic grades to ensure you find the perfect material properties for your upcoming project. As you probably know, plastic is a lighter, less reactive, and more cost-effective material as compared to metal. However, a lot of machine shops shy away from plastic CNC machining since it requires additional experience and attention to detail.

At Rapid Axis, we happily offer plastic CNC machining and additional finishing steps to ensure every part meets the needs of your project. With options like ABS, PEEK, nylon, and polycarbonate, you can unlock high-quality plastic parts. Our team will work closely with you to provide cost-effective manufacturing, precision tolerances, and results that meet your constraints.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Plastics

There are so many different plastics to choose from, and each one has its own unique set of benefits and drawbacks. At Rapid Axis, we offer plenty of common plastic materials to choose from:

ABS

Cost-effective, easy to machine, and very impact-resistant. It’s a common option for plastic prototypes and simple enclosures.

Polycarbonate

A tough and transparent material that can be used in bullet-proofing assemblies and making guards for machinery.

Nylon

Nylon is a strong and wear-resistant material that might be used in bushings and some lightweight structural components.

PEEK

PEEK is a super strong engineered thermoplastic that offers incredible heat and chemical resistance. We often use PEEK in aerospace and medical projects.

Delrin

Also called Acetal, Delrin is great for low-friction assemblies that require excellent dimensional stability.

PVC

PVC doesn’t react to acids or bases, and it’s used commonly in piping and general chemical processing equipment.

PTFE

PTFE is very lubricious and also chemically-resistant, so it’s a good option for seals and gaskets.

HDPE/LDPE

A less common option, but HDPE and LDPE are lightweight and water-resistant, so you might use them in fluid system designs or packaging designs.

Finishing Options

As a full-service machine shop, we also offer finishing steps for you to choose between. You can contact us for a full list of our finishing options, but our more common options for plastic CNC machining are:

Bead Blasting

By shooting pellets at your finished parts, we can create a matte and uniform surface through bead blasting. This removes tool marks and can hide surface imperfections. This is common in consumer products or any plastic parts that might be visible within an assembly.

Painting

With some processing upfront, it’s possible to paint plastic parts. This is generally an aesthetics-based decision, but it can also provide some UV resistance. Our painting service can put branding and color-coding information on your finished plastic parts.

Powder Coating

Powder coating takes the idea of painting to the next level. This process involves spraying a layer of powder onto a part, and then baking it until the powder has been bonded to the plastic part. Doing this can improve the durability, scratch resistance, and chemical compatibility of plastic parts. In addition, the final part will look production-ready, and you can choose from dozens of color and finish options.

Texturing

Our team can also add texturing to your plastic CNC-machined parts. This is done after the machining is finished, and it creates visual patterns or added grippiness on your parts. People add texturing to either improve the ergonomics of their parts, like the handle of a tool, or to create a more professional-looking part.

Key Features of Plastics

We offer different plastics to choose from, but generally speaking, plastic parts have some common features that make them desirable:

- Lightweight. Plastics are significantly lighter than metal parts. If you want to reduce the weight of your system without sacrificing performance, a plastic CNC-machined part might be the best option.

- Corrosion resistance. Unlike metals, plastics don’t rust and can resist a number of chemicals without any interaction at all. This makes plastic the go-to material in maritime applications and harsh environments.

- Affordability. Plastic parts can be significantly more affordable than metal parts. Not only is the raw material less expensive, but the machining operation can be simpler.

- Fast machining. A lot of plastics require less setup and considerations than metal parts. We need to monitor the speed and coolant distribution of plastic parts so they don’t melt, but they can be simpler to work with than certain metals.

- Aesthetic versatility. A huge benefit of plastics is that you can fine-tune the aesthetics of each part, with the ability to add textures, vibrant colors, and coatings. This is perfect for consumer-facing parts that need to look a certain way.

- Thermal and electrical insulation. In addition, plastics are naturally insulating, which makes them the clear choice for electrical parts and electronic components.

General Restrictions

While there are a lot of benefits of using plastic, there are still some general restrictions to be aware of.

- Tolerance Details. We offer tolerances of ±0.005 inches or tighter with 2D drawings for our CNC-machined plastic parts.

- Maximum Part Size. While we can machine plastic parts in a wide range of sizes, there are some limitations. For questions about part sizing and tolerances, give us a call.

- Surface Finish Options. We offer a range of finishing options to enhance both the functionality and aesthetics of plastic parts. Whether you need custom painting, a uniform matte finish, or improved scratch resistance, we have a solution.

Plastic CNC Machining Applications with Rapid Axis

Plastic CNC machining is used across every major industry, and in too many applications to count. Some of the more common options that come to mind are:

Medical Devices

Plastics are used in different surgical tools, housings, and equipment. In some cases, you can even use plastic in implants, if you’re using an FDA-approved material like PEEK.

Aerospace and Defense

Aerospace and defense companies use plastic to save weight in different parts of assemblies. Plastic is typically the go-to in trim pieces, housings, clips, and interior components.

Industrial Equipment

You can also use plastic in industrial equipment as a way to save money and boost chemical resistance. Components in valves, wear plates, and different jigs can use plastic CNC machining to expedite projects and save money.

Electronics and Consumer Goods

A lot of consumer goods utilize plastic to create a durable and aesthetically-pleasing device. If you look around you, you’re likely to find dozens of plastic parts, assemblies, and components. Plastic is used for enclosures, connectors, panels, casings, and much more.