Rapid Axis for PEEK CNC Machining Services

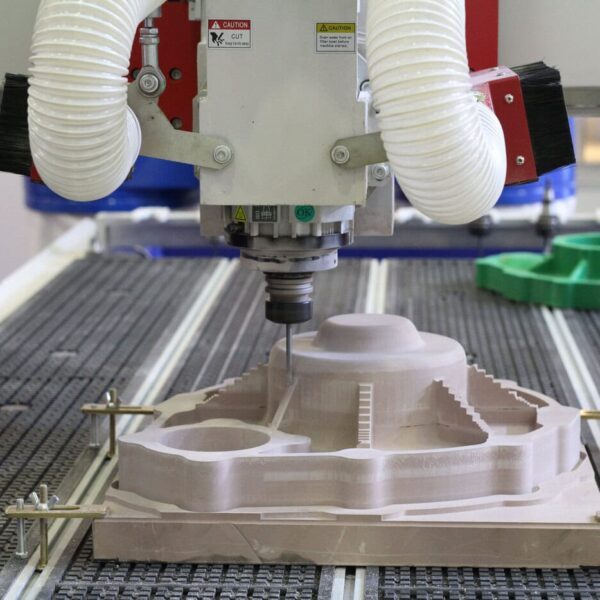

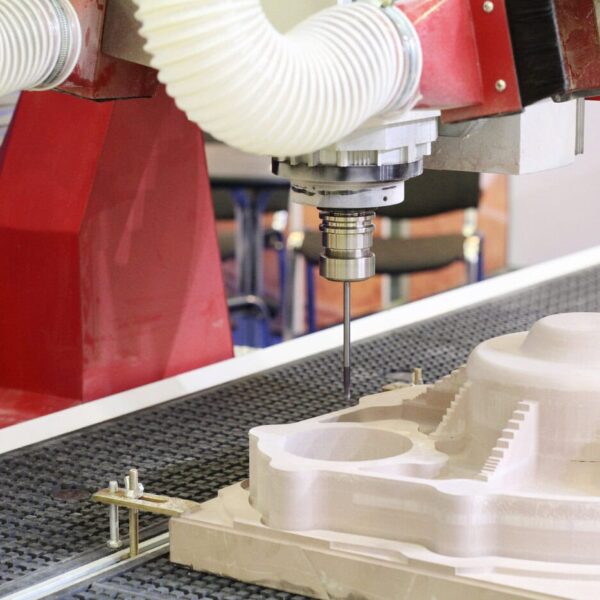

When it comes to specialty plastics, PEEK (Polyether ether ketone) is a material that stands on its own. This engineered plastic is one of the most advanced thermoplastics on the market. It has incredible mechanical, thermal, and chemical resistance, and it can be machined into complex parts with no problems. Our advanced CNC milling and turning capabilities can allow you to make prototypes and production-quality PEEK components that meet all of your needs.

Why Choose Rapid Axis for PEEK CNC Parts?

PEEK is a high-performance thermoplastic that was engineered to handle extreme conditions. It can withstand tough mechanical and environmental conditions without failing, unlike a lot of other plastics. You might choose PEEK when your parts need to be strong, resistant to heat, and non-reactive to different chemicals.

In general, PEEK can be really difficult to machine and work with if you don’t have previous experience. At Rapid Axis, we’ve machined a number of parts out of PEEK, and our expert machinists can handle your most difficult design. We know how to optimize the tool path, cutting speed, and coolant feeding to ensure every part meets your dimensional specifications without any problems. In addition, we offer a range of finishing steps to ensure every part looks and acts the way you expect. With us, you can unlock faster turnarounds and achieve higher quality than you thought possible.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

We work with a few different PEEK grades, and each configuration has a slight difference that can make it a better option for your next project:

Unfilled PEEK (Virgin PEEK)

This is the basic grade of PEEK that is generally applicable and has great mechanical and chemical resistance.

Glass-Filled PEEK (GF30)

Adding 30% glass fibers, GF30 has better stiffness and dimensional stability under load, so it can handle more stress before snapping.

Carbon-Filled PEEK (CF30)

CF30 uses carbon fiber instead of glass, making it even more wear-resistant and less electrically conductive.

Bearing-Grade PEEK (PEEK HPV)

You might see PEEK HPV used in applications where you need low friction and excellent wear properties without adding extra grease or lubricants.

Medical-Grade PEEK (PEEK Optima)

Medical-grade PEEK is reserved for implants and surgical equipment that need to be FDA-compliant. This material is great for long-term implants due to its improved biocompatibility.

Finishing Options

PEEK parts can also go through a number of finishing steps to change how the part looks, behaves, and performs. At Rapid Axis, we offer a number of options to choose from:

Polishing

By using a combination of sanding and polishing, we can create a smooth and almost reflective finish on your PEEK parts. This process removes tiny pores on the surface of your PEEK CNC machined parts, which improves the surface clarity and cleanliness of each part.

Annealing

A lot of people think that annealing only works on metals, but it also works with PEEK. At our shop, we heat up the PEEK part, maintain the temperature for a certain time, and slowly cool it back down to room temperature. This can greatly improve the mechanical properties of your parts and their dimensional stability while reducing the overall internal stress of your parts.

Laser-Engraving (Custom Marking)

We also have access to include custom marking on our PEEK machined parts. Through a laser engraver, we can mark parts for traceability, branding, or regulatory compliance. You might use this if you’re making OEM parts or designing aerospace assemblies.

Bead Blasting

Our bead blasting operation includes shooting tiny pellets against the surfaces of each PEEK part. The pellets remove surface imperfections and create a uniform, matte finish on your parts. It’s a good way to get rid of tool marks and create a consistent texture.

Key Features of PEEK

PEEK has a lot of key features that make it a widely used engineered plastic:

- Great heat resistance. A PEEK plastic part can handle temperatures up to 480°F without failing.

- Low outgassing. If you’re working in a cleanroom or aerospace environment, PEEK will meet your requirements for outgassing to avoid contamination.

- Amazing mechanical strength. PEEK has high tensile and flexural strength, so it can be used for load-bearing components or as light supportive parts. For heavier loads, you’ll need to use metal parts.

- Better dimensional stability. We can hit very tight tolerances during PEEK CNC machining, and your part will likely retain its dimensions after thermal cycling.

- Impressive biocompatibility. PEEK is approved for use in medical implants and surgical devices, so it’s a great option for medical companies.

- Chemical resistance. PEEK is inert to most acids, bases, and hydrocarbons. In addition, it can resist steam and water without absorbing the moisture.

General Restrictions

While there are a lot of benefits of using PEEK, there are still some general restrictions to be aware of.

- Tolerance Details. We offer tolerances of ±0.005 inches or tighter with 2D drawings for our CNC-machined PEEK parts.

- Maximum Part Size. While we can machine PEEK parts in a wide range of sizes, there are some limitations. For questions about part sizing and tolerances, give us a call.

- Surface Finish Options. We offer a range of finishing options to enhance both the functionality and aesthetics of PEEK. Whether you need a high-shine polish, a uniform matte finish, or custom marking, we have a solution.

PEEK CNC Machining Applications with Rapid Axis

As a material, PEEK can do things that other plastics simply cannot. This is why it is used in so many applications and across industries.

Aerospace

PEEK is a lightweight and high-strength alternative to metal parts in some aerospace systems. You might use it for general brackets, bushings, and connectors. It can be more affordable and easier to work with than metals, so you can even save money and time during fabrication.

Medical Devices

Medical devices and implants often rely on PEEK since it is a chemically-resistant, biocompatible material. You can use PEEK plastic for anything from implants to sterilizable tools and prosthetics. Since the material is also so strong and durable, you can boost the longevity of your plastic parts.

Oil, Gas, and Energy

Due to PEEK’s impressive chemical resistivity, oil, gas, and energy companies use PEEK extensively across their projects. It is a common option for valve seats and seals, and it can even be used as housings for different sensors.

Semiconductors

Since PEEK is fine to use in cleanroom applications, it is used in a number of semiconductor operations. With low outgassing and high strength, you can use PEEK for chip handling components or even wafer carriers. In addition, PEEK is resilient at high temperatures, so it can withstand different semiconductor cleaning processes without melting.

Industrial Equipment

For industrial applications, you might opt for PEEK if you want a stronger, more durable, more chemically-resistant plastic. We’ve seen PEEK used in everything from bushings to pump components and fixtures within industrial equipment.