Rapid Axis for Metal CNC Machining Services

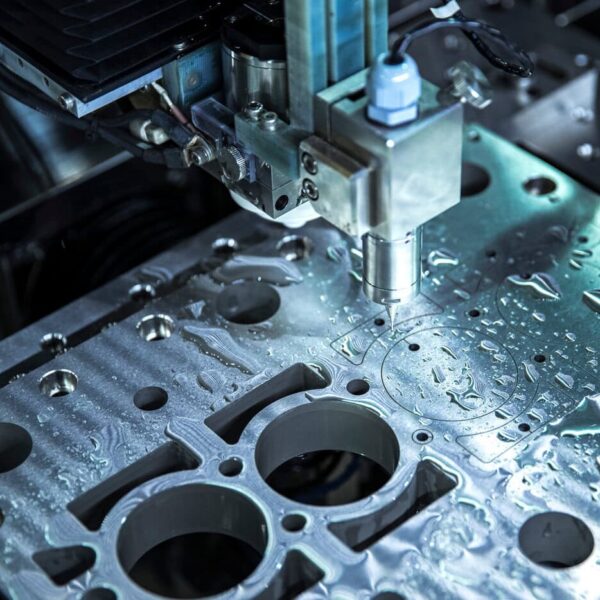

At Rapid Axis, we offer a number of metal CNC machining services. With us, you can receive high-quality precision parts made out of metal. We specialize in fast turnarounds and great quality, and we position ourselves as a manufacturing partner for companies across industries.

From aerospace-grade titanium prototypes to high-volume stainless steel parts, you can lean on our team.

Why Choose Rapid Axis for Metal CNC Parts?

As you likely know, each project can demand a different material option. Whether it’s required structural properties, aesthetics, electrical conductivity, or weight, you’ll need to choose the right material to meet the demands of your project. With our robust metal CNC machining services, you’ll be able to receive parts that work in your different applications.

We have a number of different metals to choose from, each with its own set of benefits and drawbacks. We also stock specialty alloys and materials that aren’t used as commonly.

We have a number of finishing options to choose from, which is a good way to ensure your parts look and perform the way you intend.

With a number of 3-, 4-, and 5-axis CNC machining centers, you can trust our team at Rapid Axis. Our trained machinists have hands-on experience with all of the metals and alloys we offer, so you’ll get the best results.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

There is a wide range of different metals that you can choose from. Some of the more common options that make up our metal CNC machining services are:

Aluminum

A great mix of low weight and high strength, aluminum is one of the most common metals used in our shop. We have aerospace-grade aluminum as well as general-use 6061 alloys to meet your automotive or consumer projects.

Stainless Steel

Stainless steel is a stronger and heavier material that resists corrosion well and can be sanitized for use in cleanrooms. It’s used in structural applications, medical devices, and marine hardware.

Mild Steel

Mild steel doesn’t have the same corrosion resistance as stainless steel, but it is more cost-effective and tends to be easier to weld and manufacture. We suggest powder coating any mild steel part so it will be more durable long-term. This metal is great for brackets, frames, and enclosures.

Tool Steel

Tool steel offers high hardness and great dimensional stability, and we use it in dies, molds, and cutting tools.

Copper

Copper is used primarily in electrical projects since it has high thermal and electrical conductivity. It’s also microbial, so some medical projects opt to use copper.

Brass

Brass is another corrosion-resistant metal that is easy to machine and offers a nice aesthetic finish. Brass can be used for HVAC parts, fittings, or decorative components.

Titanium

Titanium has an incredible strength-to-weight ratio, and it is biocompatible. As a result, you can use titanium in high-stress applications, aerospace projects, medical implants, and for various defense projects.

Finishing Options

We offer a wide range of finishing options for multiple different materials. The right finishing process can completely transform your part, adding longevity and better aesthetic appeal.

Bead Blasting

Bead blasting involves firing tiny pellets at the finished metal part, removing surface imperfections and creating a uniform layer. Bead blasting also reduces the reflectivity of parts and creates a matte finish.

Anodizing (Aluminum Only)

For aluminum parts, you might consider anodization. Anodizing is an electrochemical process that adds a layer of oxide to the outside of aluminum parts, which improves corrosion resistance and makes parts more durable.

Powder Coating

Powder coating involves adding a dry powder and curing the part. It creates a uniform, aesthetically-pleasing layer of protection around your parts. We can powder coat a part in almost any color, and it is a long-lasting coating that adds abrasion resistance to your metal parts.

Chem Film / Alodine

Aluminum and steel parts can go through a conversion coating process, namely chem film or Alodine, that improves corrosion resistance and retains electrical conductivity.

Electroplating

Metal parts can also go through an electroplating process, which applies a thin metal coating to help with appearance and improve corrosion resistance of your parts. It also adds conductivity and improves the surface hardness of your parts.

Painting

For aesthetic purposes, we also offer standard wet painting. This can transform your parts by adding branding, color-coding, or color-matching for retrofitting parts.

Key Features of Metal

While every metal has unique properties, all metals share some common strengths:

- Strength and durability. Metals provide superior mechanical properties, including high tensile strength, impact resistance, and load-bearing capacity.

- Electrical and thermal conductivity. Many metals excel at conducting electricity and heat. Copper and aluminum, for instance, are widely used in wiring and heat sinks.

- Malleability and formability. Metals can be shaped through various processes including forging, stamping, rolling, and bending without breaking. This allows for complex geometries and enables both mass production and custom fabrication techniques.

- Temperature stability. Metals maintain their structural integrity across wide temperature ranges, from cryogenic conditions to high-heat environments. Different alloys can be selected based on specific thermal requirements of the application.

- Precision manufacturing capabilities. Metals can be machined to extremely tight tolerances using precision manufacturing methods. This makes them suitable for applications requiring exact specifications and repeatability.

General Restrictions

While there are a lot of benefits to using metal for your parts, there are still some general restrictions to be aware of.

- Tolerance Details. We offer tolerances of ±0.005 inches or tighter with 2D drawings for our CNC-machined metal parts.

- Maximum Part Size. While we can machine metal parts in a wide range of sizes, there are some limitations. For questions about part sizing and tolerances, give us a call.

- Corrosion susceptibility. Many metals are prone to oxidation and corrosion when exposed to moisture, chemicals, or certain environments. It’s critical to use the correct coating or treatment to preserve the integrity of metal parts.

Metal CNC Machining Applications with Rapid Axis

With a variety of metals to choose from, our metal CNC machining services serve a huge range of applications. Within almost every industry, it’s easy to think of multiple examples of where metal CNC-machined parts are used.

Aerospace Industry

Metal CNC parts are used in airframe components, structural brackets, engine mounts, and seat components.

Automotive Industry

Automotive companies use metal CNC machining to create gearbox housings, engine components, suspension parts, and mounting plates.

Medical Industry

You can use metal parts for surgical instruments, diagnostic equipment, orthopedic implants, and Class I devices.

Electronics Industry

Within the electronics industry, metal is used in heat sinks, RF enclosures, bus bars, EMI/RFI shielded components, and much more.

Robotics and Automation Industries

CNC-machined metal parts are used for structural frames, linkages, precision gears, shafts, and end-of-arm tooling.

Industrial Machinery Industry

Industrial machinery relies on a lot of metal CNC parts, including mounting plates, baseplates, tool fixtures, and flanges.