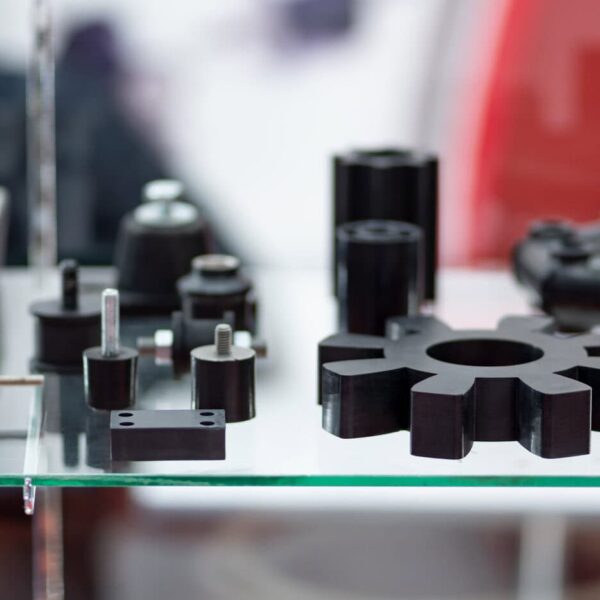

Rapid Axis for Acetal (Delrin) CNC Machining Services

At Rapid Axis, we offer Delrin CNC machining services that can take your operation to the next level. Delrin is the brand name of acetal (POM) plastic, a thermoplastic that strikes a nice balance between mechanical strength, dimensional stability, manufacturability, and performance.

Our machinists can create one-off prototypes, small production runs, or high-volume production runs for your team. We always go the extra mile to ensure every component is perfect and within your tolerances.

Why Choose Rapid Axis for Delrin CNC Parts?

Delrin is a go-to plastic for a lot of different companies, especially in chemical and industrial settings. You’ll notice that acetal parts have a lot of key benefits like low water absorption and great chemical resistance that make this material a great option across industries.

Our team has been working with Delrin for a long time, and we know all the ins and outs of this temperamental material. Delrin tends to deform from the heat during manufacturing, which is why we need to be really careful with each Delrin part we make. If you choose a manufacturer that isn’t familiar with Delrin, you’re signing up for trouble — luckily, our experts at Rapid Axis know the right machining parameters and coolant to use to avoid issues.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

When it comes to Delrin, there are a few common material options that people choose. At Rapid Axis, we offer a variety of material options to ensure you get the best performance for each of your parts:

Delrin Homopolymer

This option is great for structural parts or high-load areas. This grade has higher mechanical strength and toughness, plus better wear resistance, but it’s less resistant to hydrolysis.

Acetal Copolymer

This copolymer is a little weaker, but thrives in wet environments since it has better resistance to water, heat, and chemicals.

Delrin AF (PTFE-filled)

The added PTFE enhances the wear performance and creates a self-lubricated part with much lower friction. However, this specialty grade Delrin typically costs more and has a lower tensile strength.

Glass-Filled Acetal

Adding glass makes the acetal a lot stiffer and more dimensionally stable. It’s a good option for precision fittings or structural brackets, but you need to watch out because it is more brittle and less impact-resistant.

Black or Natural Delrin

Black and natural Delrin are colored options that are UV-stabilized and okay to use in cleanrooms or in food-contact applications.

Finishing Options

Once we machine a piece of Delrin for you, we can put the part through a variety of different finishing steps. Our most common finishing options for Delrin CNC-machined parts are:

Bead Blasting

Bead blasting applies a light abrasive to the part, smoothing out any surface imperfections and creating a uniform surface. It makes the surface matte and non-reflective, which can also help with the aesthetics of your parts.

Custom Deburring

If your Delrin machined parts will be manually handled or will interact with other parts, it’s a good idea to deburr all of the holes and break the sharp edges. This is a manual operation that essentially smooths all of the otherwise sharp parts of your Delrin units.

Polishing

Polishing is another way to change the aesthetics of your parts. In this case, they will achieve a glossy finish which is great for customer-facing parts or any cosmetic parts. Since Delrin has a low coefficient of friction, it polishes up nicely and the finished part looks amazing.

Chemical Cleaning

Another option is to remove machining oils and dust through chemical cleaning. It gets your parts ready for assembly and inspection, and it is a necessary step if you’re working in a cleanroom.

Laser Engraving

Laser engraving is a way to add text or images to your parts without needing stickers or adhesives. It’s a way to brand your parts, add important instructions, or label parts. We see this a lot in cleanroom projects or industrial projects.

Key Features of Delrin

- Easy to machine. Although it’s easy to mess up a Delrin part on a CNC machine, once you have experience working with this material and know what you’re doing, Delrin is surprisingly easy to machine and create assemblies out of.

- Low water absorption. POM and POM-C are both stable in humid or wet environments.

- Strong and stiff material. Delrin is strong enough to potentially replace metal components in light-duty applications.

- Low friction. Delrin can also be used in dry-running bearings and in applications where parts need to slide and rotate without additional oils or lubricants.

- Great chemical resistance. Generally speaking, acetal plastic is resistant to a lot of chemicals, including various fuels and solvents.

General Restrictions

While Delrin has a lot of versatility, there are some restrictions that come with Delrin machining.

- Tolerance Details. We offer tolerances at ±0.005 inches or tighter with 2D drawings for our CNC-machined Delrin parts.

- Maximum Part Size. We can make acetal parts of nearly any size, but we do have some size restrictions. Contact us with your project requirements and we’ll tell you if we can handle the size and tolerancing requirements for your acrylic parts.

- Surface Finish Options. We have a number of finishing operations to choose from that will remove surface imperfections, prep your part for the cleanroom, and more.

Delrin CNC Machining Applications with Rapid Axis

We’ve created Delrin CNC parts for a variety of industries and applications. In reality, acetal plastic is one of the more common plastic options that you will find in industrial settings. Here are some common parts you might find in big industries:

Automotive

Car manufacturers can use Delrin for bushings and spacers, as well as different clips and linkages. Since Delrin can be made into custom parts and can be mass-manufactured with ease, automotive companies often use Delrin.

Medical Devices

Since Delrin can be sterilized, different medical companies will use this material for surgical tools, brackets, and even non-implantable sterilizable components. Delrin has the strength required to handle bigger forces without breaking, making it a great choice for a lot of medical projects.

Electrical and Electronics

Since Delrin is non-conductive, it can be used near electronics without any issues. As a result, electronics companies will use Delrin for cable clips, switch components, actuator gears, and insulators or spacers.

Consumer Products

Delrin is a great option for consumer products because it looks like a high-quality material and it’s strong enough to handle repeated use. Anything from furniture hardware to locking snap-fit joints and appliance parts are made out of Delrin across the globe.

Industrial Equipment

Some industrial companies use Delrin as their go-to plastic since there are so many upsides to this material. You can easily use Delrin to make gears, sprockets, wear pads, linear bearings, and various jigs.