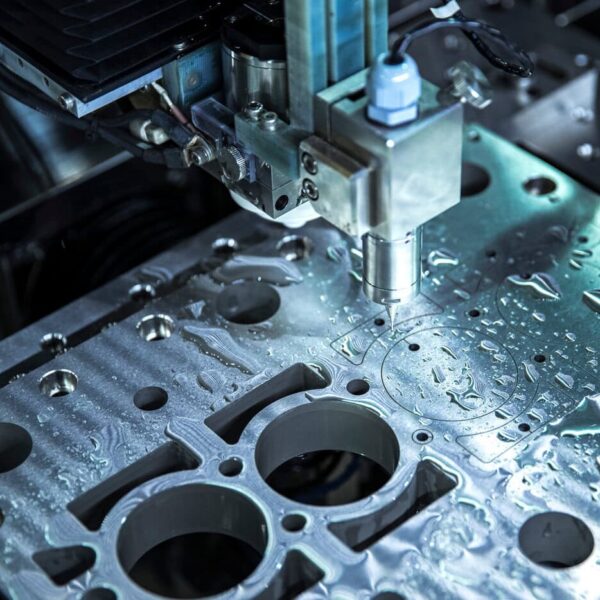

Rapid Axis for Aluminum CNC Machining Services

At Rapid Axis, our goal is to be a manufacturing partner and provide high-precision aluminum CNC machining services for companies across the nation. With years of experience, we’re able to handle a variety of complex and simple machining projects. We have a long history of providing high-quality aluminum CNC machining services to OEMs across North America.

Why Choose Rapid Axis for Aluminum CNC Parts?

Our custom aluminum CNC machining services have been the go-to choice for companies across industries and applications. We’ve created aircraft frames for aerospace companies, enclosures for electrical companies, and surgical equipment for medical device companies — we like to say that if you can design it, our team at Rapid Axis can make it.

You’ll notice the difference when you choose our aluminum CNC machining service for your next project. We specialize in high-quality, precision CNC work that meets your budgets and timeline expectations. We are a manufacturing partner that can create prototypes, low-volume parts, and high-volume parts alike — as a scalable option that offers more under one roof, choosing Rapid Axis for your next project is a great idea.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

We offer a wide range of aluminum alloys to make sure we can meet the demands of your operation. Some of our more common options are:

6061 Aluminum

The most common option, hailed for its great corrosion resistance, manufacturability, weldability, and overall impressive strength-to-weight ratio.

7075 Aluminum

A stronger alloy that can withstand long-term stress, but the alloy is more difficult to machine.

2024 Aluminum

Even better strength-to-weight ratio and durability, but comes with a worsened corrosion resistance.

5052 Aluminum

A specialty alloy that’s reserved for marine environments thanks to its incredible corrosion resistance, but it is not as strong as 6061 or 7075.

3003 Aluminum

A more unique alloy that is more affordable, offers great corrosion resistance, and is easy to bend and shape. However, it’s not as strong as other alloys.

Finishing Options

In addition to high-quality machining, we also offer a range of finishing options to ensure every aluminum part is perfect. Our finishing options can help with the aesthetics, performance, and longevity of your parts.

Anodizing

Our anodizing services enhance corrosion resistance, durability, and wear resistance for each part. We can also dye the anodized layer in various colors, allowing each part to look great and work even better.

Conversion Coating

This process treats aluminum parts with a chemical solution to create a protective layer and improve the part’s corrosion resistance without changing how the part looks. This is common practice in aerospace and military applications.

Plating

This option adds a layer of metal to the surface of your parts, which helps with corrosion resistance, wear resistance, and the aesthetics of the part. It strikes a nice balance between a decorative and functional finish

Key Features of Aluminum

Aluminum is one of the most common materials that we work with, and it’s an ideal option for major industries like medical, aerospace, defense, and more.

Aluminum is a great choice since it’s affordable, readily available, and easy to work with. Most aluminum alloys also boast great strength-to-weight ratios and impressive electrical conductivity, so it’s a good choice for specialty applications as well.

General Restrictions

Aluminum is a great material choice, but there are some restrictions that you should be aware of:

- Tolerance Details. We offer tolerances of ±0.005 inches or tighter with 2D drawings for our CNC-machined aluminum parts.

- Maximum Part Size. We can machine aluminum parts in a wide range of sizes, but like any machine shop, we have limitations. Send us your project specifications, and we’ll confirm whether we can meet your size and tolerancing requirements.

- Surface Finish Options. We offer various finishing processes to improve the appearance and performance of machined aluminum parts, including anodizing, conversion coating, and plating.

Aluminum CNC Machining Applications with Rapid Axis

We’ve worked with countless industries and provided aluminum CNC machining for major companies across the US. This is largely due to the versatility of aluminum and the quality of work we produce at Rapid Axis. In our experience, five industries that commonly use aluminum are automotive, aerospace, medical, electronics, and robotics.

Automotive

Weight reduction is a big deal for any automotive company — it helps with fuel efficiency and performance, which are two of the most important metrics of any consumer vehicle. This makes aluminum a great choice, thanks to the favorable strength-to-weight ratio and cost-effectiveness of the material. In addition, most aluminum alloys are easy to machine and form, saving even more time and money during each vehicle’s manufacturing.

Aerospace

Aerospace applications emphasize performance, durability, and weight of each of their parts. Since aluminum does great in all three of these categories, it’s a common choice for aerospace projects. Anything from aircraft frames to engine components and landing gears often use aluminum. Plus, our ability to meet tight tolerances while machining aluminum ensures every part is compliant.

Medical

The medical field commonly uses aluminum for surgical instruments and medical device housings. Aluminum is corrosion resistant and lightweight, so medical companies often choose this material. In addition, aluminum can be cleaned easily and is non-reactive, so it has good biocompatibility with most applications within the medical industry.

Electronics

Aluminum has excellent thermal conductivity and electrical conductivity, so you’ll see it used often in the world of electronics. We’ve created enclosures, connectors, and heat sinks out of aluminum for various projects in the past. Since we can hit tight tolerances, we can also fabricate parts for high-performance electronics.

Robotics and Automation

We’ve noticed a trend of using aluminum as the default metal for most of the robotics and automation projects we’ve worked on in the past. It’s largely thanks to the durable and lightweight nature of aluminum, and you can find it used in robot arms, actuators, mechanical frames, and supporting structures. Since we specialize in fabricating custom parts, we’ll meet the needs of your project and unlock a new level of flexibility during the design of your project.