Rapid Axis for Acrylic CNC Machining Services

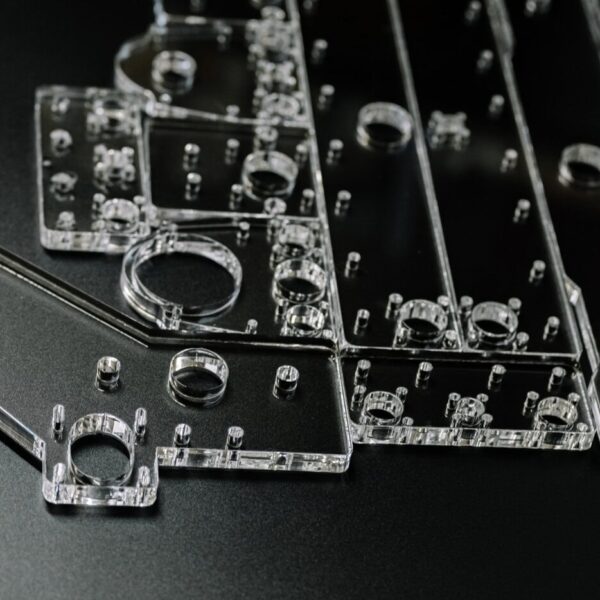

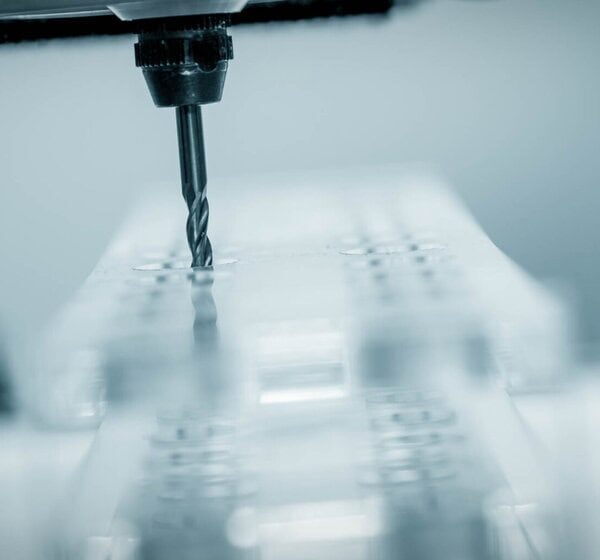

Acrylic is also known as PMMA (polymethyl methacrylate), and it is a transparent material that can be difficult to machine. In general, acrylic is brittle and tends to chip easily, so you need an experienced machinist in your corner, like our team at Rapid Axis. We’ve been offering acrylic CNC machining services for a while, and we know how to produce acrylic prototype and end use parts with tight tolerances and smooth finishing.

Why Choose Rapid Axis for Acrylic CNC Parts?

As a plastic material, acrylic is a lightweight, transparent, and shatter-resistant alternative to glass. It’s easier to work with and generally more affordable, so acrylic is a great option for many industrial applications.

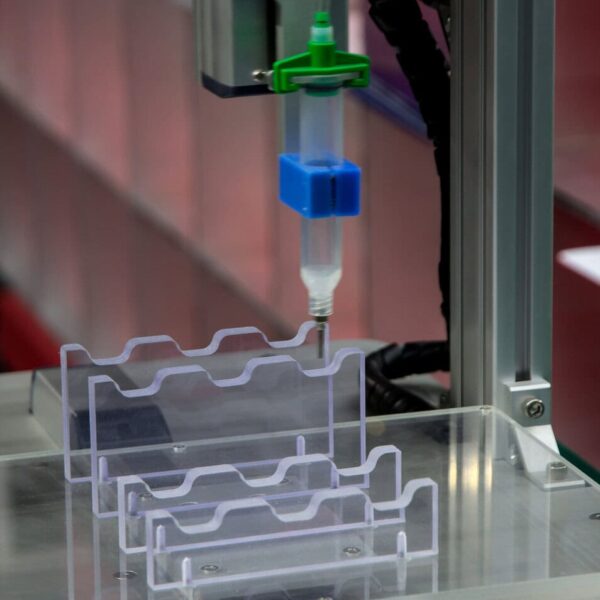

At Rapid Axis, we can make custom acrylic parts for your upcoming projects. Our acrylic CNC machining services will transform sheets and blocks of acrylic into prototype and production parts that meet the needs of your operation.

Our team can help with your rapid prototyping, small production runs, or full-scale production needs. We also offer a range of finishing steps — we do more under one roof so you can save time and money on every project.

Parts made to customer drawing tolerances

Quick lead times and service

Finishing and second operations supported

Available Materials

At Rapid Axis, we have a few different types of acrylic to choose from:

Clear Cast Acrylic

This option is more expensive and has a lower impact strength, but it comes with better optical clarity and lower internal stress. This choice is best for displays, decorative parts, or lenses.

Clear Extruded Acrylic

Another clear option, this version is less expensive and typically has tighter thickness tolerances. The optical clarity is less than clear cast acrylic, but it’s still a great choice for protective screens or enclosures.

UV-Stable Acrylic

This acrylic has even better resistance to yellowing and degradation from UV exposure, and our clients typically choose it for outdoor signage, automotive trim, or covers for lights.

Impact-Modified Acrylic

Impact-modified acrylic offers better impact resistance and higher toughness with less optical clarity. However, it’s the better option in industrial settings where impacts are expected.

Colored Acrylic

Finally, we offer acrylics in various opaque, translucent, and tinted options to limit light transmission or match your branding.

Finishing Options

If you want to take your acrylic CNC machined parts a step further, you can choose from our selection of finishing options.

Bead Blasting

Bead blasting is done to smooth out a surface and remove tool marks or any other minor surface imperfections. The result is a matte part that has a more uniform surface.

Flame Polishing

We can use flame polishing to create a glossy, glass-like edge on your parts. This is preferred for applications where aesthetics and clarity are really important.

Vapor Polishing

Our vapor polishing finish is another way to remove microscopic surface imperfections. This option creates acrylic parts that are more transparent and clear. If you have a viewing window in a piece of equipment or machinery, we would highly suggest vapor polishing.

Buffing and Hand Polishing

Another way to achieve a high-gloss finish is through a physical polish like buffing or hand polishing. This option is preferred for larger, flat surfaces that need to be shiny, like decorative panels and consumer-facing parts.

Silk Screening or UV Printing

We also provide silk screening and UV printing to add logos, instructions, or decorations without damaging the transparency of your acrylic CNC parts.

Key Features of Acrylic

Acrylic has a lot of great features, which is why it’s a common option when it comes to thermoplastics across industries:

- Optical clarity. A stock piece of acrylic allows for up to 92% light transmission, which is higher than most plastics and some glass options.

- UV resistance. Most of the acrylic we use will resist yellowing and degradation from prolonged UV exposure.

- Lightweight. Acrylic weighs half as much as glass which can help save weight across your machines and equipment.

- Chemical resistance. It also resists a lot of acids, bases, and cleaning agents. This is why you’ll see acrylic used in chemical facilities or medical environments.

- Ease of manufacturing. With our experience and expertise, there are no issues manufacturing a piece of acrylic. We can also thermoform or bend a piece of acrylic after it is CNC machined.

General Restrictions

Acrylic is a versatile and durable material, but there are some restrictions:

- Tolerance Details. We offer tolerances at ±0.005 inches or tighter with 2D drawings for our CNC-machined acrylic parts.

- Maximum Part Size. We can make acrylic parts of all sizes, but we do have some size restrictions. Contact us with your project requirements and specifications and we’ll tell you if we can handle the size and tolerancing requirements for your acrylic parts.

- Surface Finish Options. An acrylic machined part might show tool marks and scratches. If you want a uniform surface finish, we have a number of finishing operations to choose from that will completely eliminate surface imperfections.

Acrylic CNC Machining Applications with Rapid Axis

As we mentioned, acrylic is a popular material option across industries. More specifically, you might use acrylic in these applications:

Automotive

Automotive companies lean on acrylic for their gauge covers, light lenses, and instrument panels. Acrylic won’t shatter like glass and it is a lighter and less expensive option, so automotive companies can use acrylic to get a better result.

Medical and Healthcare

A lot of guards and protective shields are made with acrylic since the material is transparent and can withstand a shock.

Consumer Products

In the world of consumer products, anything from décor to furniture and retail displays can be made out of acrylic. With consumer parts, acrylic is a good option since it is easy to manufacture and a less expensive option — it allows companies to offer more competitive prices while matching the performance of their competitors.

Industrial and Commercial

Plenty of industrial companies use acrylic parts for a wide range of applications. A super common example is a sight glass in any type of machine or equipment. When you need a clear boundary to observe liquids, gases, or parts in motion, you can use acrylic. Acrylic is also used in machine guards and control panel covers.