Rapid Axis for MJF Printing

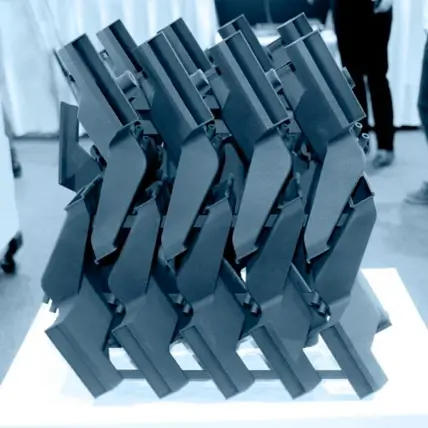

Rapid Axis provides competitively priced, quality parts; quickly. With a high MJF production capacity at our disposal, Rapid Axis is well suited for prototype and production MJF projects alike. Rapid Axis keeps most commonly processed materials available on demand as well as offering in color MJF printing for the best looking components straight off the machine.

Why Rapid Axis is the best choice for MJF

Our large MJF capacity and various equipment setups at our disposal means we can process high volumes of components in a variety of materials and colors. Typical lead times for MJF parts are just days, sometimes as short as one day. We have no minimum quantity order and offer the highest level of service available for your project questions, before the start of your project or after the components ship. Dedication to service and quality easily make Rapid Axis the best choice for your next MJF project.

Parts in days

Prototyping or production

Excellent customer service

Technical

General Tolerances: +/-.012” to 3.937” and +/-.003” for every inch beyond

Build Size: 380mm x 284mm x 380mm

Cosmetics: Bead blast, print in color, dye, paint

2nd Operations: Post op machining, hardware installation

Equipment: HP Inc

Materials: PA12, PA 12 Glass Bead, PA11, PP, Estane 95A TPU, Ultrasint 88A TPU

See Materials page

What is MJF Printing?

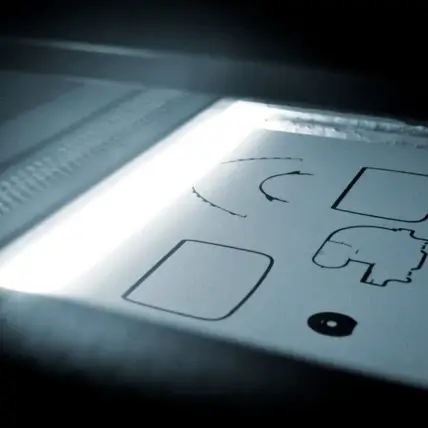

Multi-Jet Fusion (MJF) printing is a high-quality form of 3D printing. The key difference with this form of printing is that the parts can achieve some impressive mechanical qualities. The motion looks more like a traditional inkjet paper:

First, a layer of nylon powder is laid out. Then, an arm deposits detailing agents selectively across the powder. The agent gets deposited where the 3D object is going to be built, so it’s essentially tracing the object one layer at a time.

These agents get heated and fused together, bonding the nylon powder and fusing it. Another layer of powder is laid down, the depositing arm shifts up a fraction of an inch, then the process is repeated. Doing this builds a 3D part one layer at a time, from the bottom to the top. After a period of time, the part is completed.

The differences between MJF and other forms of 3D printing are the material used, method of fusion, and how the part is built. As a result, parts are stronger, more mechanically consistent, and higher quality. It’s also harder to separate parts at layer intersections since it’s fused together instead of laid on top of each other.

In industrial settings, you’ll see more MJF parts and fewer FDM parts.

MJF Printing Applications

The difference between 3D printing styles can get confusing since there are so many. In an effort to clear things up, let’s cover some of the major MJF printing applications and talk about the benefits of this printing style.

Faster Fabrication

Since MJF printers work like inkjet printers, the fabrication takes a lot less time. It’s among the fastest printing options on the market.

As a customer, this means that you will get your parts quicker. On top of that, our team at Rapid Axis prioritizes quality and turnaround time, so you don’t have to worry about receiving a defect or missing a deadline.

We can set up multiple units on a single print function. This means that the printer will create them all simultaneously and get your parts out faster by avoiding a queue at the printer.

Compared to CNC machining, MJF is significantly faster. We can print parts at a fraction of the time it would take us to machine them. The other benefit is that printers can run overnight, even when no one is in the shop. The same isn’t true for CNC machines.

As a result, you can have your MJF-printed parts within a few days, whereas metal CNC machined parts could take a week or more.

The Mechanical Properties are Consistent

Since MJF printers deposit an agent and heat up nylon powder in a specific pattern, the overall material properties are favorable. As a material, nylon offers good tensile strength and elongation as compared to more traditional 3D printing plastics.

This means that you can use an MJF-printed part in applications where an FDM-printed part falls short.

Compared to other nylon-based printers, MJF parts are much more consistent throughout. Again, this goes back to the manufacturing method used in this type of printer. Each layer is fused to the previous layer, and the heating element directs the energy very well.

You won’t have pockets within the part that aren’t as strong or flexible as surrounding areas. With parts that have consistent mechanical properties, you can broaden the range of parts that you print. Since they’re more reliable, you can start installing MJF parts on your production line without any worries.

Their strength still doesn’t compare to a machined metal part, but the nylon pieces can be much easier to design, make, and install.

Improved Surface Finish

One of the key differences between MJF and any other 3D printing style is how good the surface finish is, right out of the printer. Other printers might require finishing steps like sanding or glass beading after. With MJF, you can take a part and send it right to a customer.

This is because of MJF’s increased resolution. In 3D printing, “resolution” refers to the height of each layer. With tall heights, parts will look more blocky and geometric. Our MJF printers can achieve resolutions as low as .004” layer thickness with features as small as 0.020”. This results in a rounded, smooth finish without additional steps.

Get Functional Parts

Some people think that 3D printing is just for hobbyists who want to make aesthetically-pleasing sculptures. MJF printers prove that this idea isn’t true anymore. It’s rapidly become a replacement for short-run production in injection molding or urethane casting.

We’ve had plenty of customers get an MJF part from us then install it directly onto their production line. Mechanically, these parts are no different than a part that was machined out of solid Nylon 12. That’s to say that any application that could benefit from a flexible plastic, can benefit from an MJF-printed part.

We can create flexible brackets or mechanical arms that have good strength. They’ll be fabricated faster and cost less than the same part machined out of nylon.