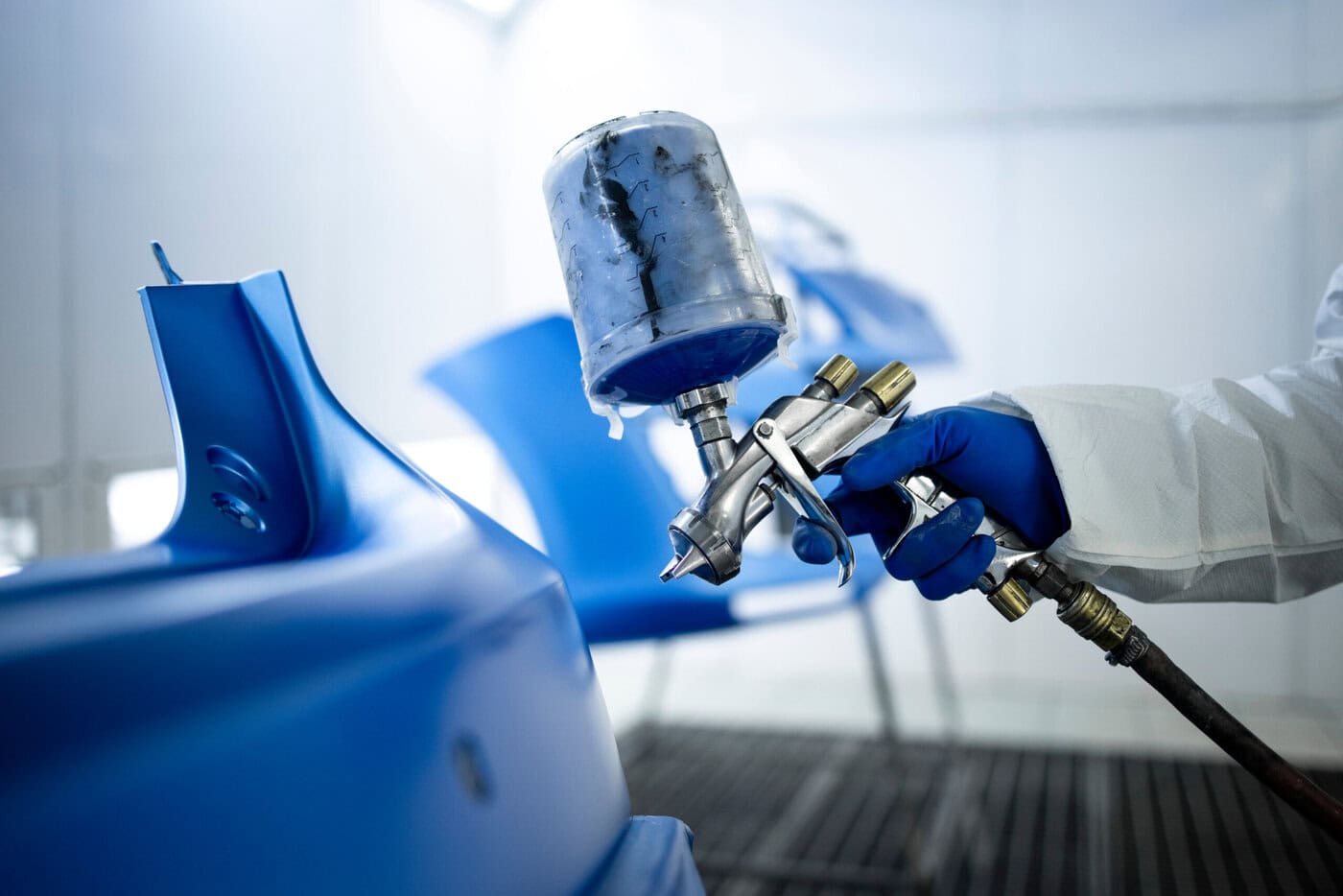

Available Finishes for Urethane Casted Parts

Urethane casting is a versatile manufacturing process that produces high-quality, functional prototypes and low-volume production parts. One critical aspect that significantly impacts the final product's performance, aesthetics, and feel is the surface finish. The finish itself won’t change the core material properties of your parts,…