Intro

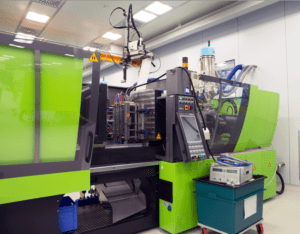

Injection molding is one of the most common forms of manufacturing products in bulk. The medical device industry adopted injection molding as their gold standard for mass-produced parts, and there are a lot of reasons why.

In this guide, we’ll give an introduction to plastic injection molding as it pertains to the medical device industry. We’ll review some materials you can choose from and some of the biggest benefits that this industry sees from this manufacturing option.

What Materials Can You Choose From?

First, it’s important to mention which materials you can choose from. While there are dozens of options, the four most common choices for the medical device industry are:

- Polyetheretherketone (PEEK). PEEK boasts some impressive mechanical properties, and it performs really well. Notably, it has great resistance to wear, contamination, thermal degradation, and radiation. You might see PEEK used in load-bearing implants.

- Polystyrene (PS). PS is a strong, stiff, sturdy option. It’s great at absorbing an impact and it’s one of the stronger options. Our customers like how aesthetically pleasing it looks after being injection molded, and it’s really easy to hit tight tolerances with it. You might see PS used in commodity, one-off, packaged medical devices.

- Polyethylene (PE). PE comes in different levels of durability. The highest is UMHV, then HDPE, and finally LDPE. You might see this product used in prosthetics.

- Polypropylene (PP). PP is one of the most common options when it comes to injection molding. It’s highly durable, very rugged, and low-cost. You might see this product used in lab equipment and medical vessels.

Benefits of Plastic Injection Molding in the Medical Device Industry

If you are considering using plastic injection molding for an upcoming medical device project, consider the following benefits.

It’s Cost-Effective

One of the biggest benefits of injection molding with plastic is how low-cost the product becomes at a large enough scale. It’s common to only pay pennies per unit when you’re dealing with mass production.

Plenty of Materials to Choose From

Earlier we mentioned four materials to choose from, but there are dozens of different plastics that you can injection mold with. This means that you can fine-tune the material properties of your product by picking the perfect material.

Each material choice has a unique set of benefits and drawbacks, but it opens the door to further customization of your final product.

The Units are Durable

Injection-molded parts are known to be durable. Since the operation doesn’t require any cutting or fusing, the finished part is solid and strong. With 3D printing, parts might break between layers of fabrication, but injection-molded parts don’t have the same issue.

Though injection molded parts aren’t as strong as metal pieces, they’re significantly less expensive, easier to make, and easier to color.

This level of durability means more success in your testing, and fewer issues with customers in the future.

Contamination-Resistance is Common

We know that a big part of making a medical device is passing all of the FDA requirements. A lot of those requirements revolve around contamination resistance.

With porous materials, parts that go through cutting or machining, and certain fabrication methods, it’s very difficult for the final product to avoid contamination.

Through injection molding, the final product is easier to sterilize and keep contaminant-free. Thanks to this, you’ll likely have an easier time passing FDA requirements that pertain to contamination resistance when you choose injection molding.

Superior Accuracy and Precision

Above everything else, injection molded parts are highly repeatable. This is a result of the accuracy and precision throughout the process. The molds used are held to incredibly tight tolerances, and the process of injection molding helps uphold the accuracy even further.

We know that medical devices could be ruined if they’re off by just a few mils (0.001”), so we suggest injection molding to keep the tolerances as tight as possible.

Easy Coloring and Finishing Steps

In some cases, you might want to add branding or certain colors to your devices. You might rely on color to:

- Warn the user of dangerous parts of your device

- Calm the user

- Allow the user to see inside of the device/ vessel

- Provide instructions for using your device

- Match a skin tone for less noticeable application

Regardless of your color needs, injection molding will likely meet your requirements. With injection molding, the plastics used are easily colorable and they can go through a series of finishing steps without any problems.

Conclusion

We just covered the basics of plastic injection molding in the medical device industry. This manufacturing style is widely versatile, so there are plenty of applications. If you want to learn more or get started with your medical device project today, reach out to our injection molding experts at Rapid Axis. We can guide you through this process and handle all the manufacturing for you.