Intro

Using the right draft angle in your injection molding design can help with the final quality, improve your cycle time, and save you money. How is that possible? It all revolves around picking the perfect draft angle and applying it to the right surfaces.

In this guide, we’ll explain everything you need to know. We’ll provide definitions, examples, and some benefits of choosing the right injection molding draft angle.

What Is a Draft Angle?

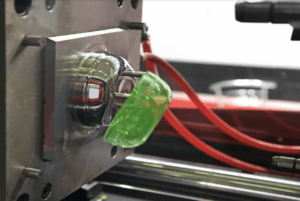

A draft angle is something used in injection molding and die-casting operations. It’s the idea of adding a slope or angles to the upright walls of your mold or cavity. Draft angles are typically added to vertical walls, not the flat bottom of molds.

Why Injection Molding Draft Angles are Important

Why are draft angles added to injection molded parts? It makes the removal of the part a lot easier. It does this by reducing the friction between the injection molded part and the recess of the cavity within the tooling.

With less friction, parts can be removed without damaging the parts when they get stuck, since they won’t get stuck in the first place.

Another benefit of draft angles is that they can preserve the final finish of the molded parts. Friction is known to make for rougher surfaces on parts, and a lack of draft angles comes with a lot of added friction.

Other injection molding experts mention that draft angles help to protect the tooling when you’re making especially large parts. When you’re molding a heavy piece of plastic, thin walls within the tooling can get bent or damaged. With a draft angle, the weight does less damage.

Where to Apply Draft Angles

In reality, a draft angle should be added to every mold used in your injection molding application. U-shaped, T-shaped, and cylindrical cavities could all benefit from a draft angle. Any surface that is parallel to the direction that the liquid plastic flows should have some form of draft angle.

The Secret to Finding the Perfect Draft Angle

If the draft angle is too severe, your part could suffer, so there’s a delicate balance when it comes to the exact angle. In general, a 1° or 2° draft angle will be more than enough. Some manufacturers provide a 3° draft angle for especially deep parts, or cavities that create very heavy plastic parts.

Going above 3° is typically not advised — it can create parts with rough finishes or noticeable deformities to your parts.

For low-friction materials like nylon, using less than a 1° draft angle might be fine. Again, it is largely contingent on your part, your application, and the size of the cavity. If you want to discuss specifics, you can ask one of our injection molding experts at Rapid Axis.

Benefits of Injection Molding Draft Angles

We’ve discussed some of these points, but let’s talk about the specific benefits of adding draft angles to injection-molded parts:

- Faster cycle times. When parts can be quickly removed, your entire cycle time speeds up. Fighting with each unit to remove it from the cavity wastes time and hurts your bottom line, and a draft angle avoids this issue.

- Better surface finishes. Draft angles reduce friction which results in a smoother surface on each of your parts.

- Longer cavity life. With less friction, there’s less wear and tear on your tooling after each use, resulting in a longer cavity life. This also means that you can make more units from a single tooling, reducing the price per unit.

- Simpler ejection. Ignoring a draft angle might require an expensive and complicated ejection system just to remove your parts from the cavity. Injection molding companies are happy to offer this because it generates a lot of profit for them, but it means you have to spend too much.

Disadvantages of Injection Molding Draft Angles

Draft angles are good in most applications, but there are some situations where they fall short. Here are some disadvantages of injection molding draft angles:

- Tooling design is trickier. It’s a lot easier to design square corners and flat sides, so draft angles can complicate things. It also means that the tooling is more difficult to manufacture.

- The tooling could be more expensive. Since it’s harder to make, the tooling is also more expensive. Since tooling is the most expensive part of injection-molding a part, this is bad news.

- It’s tough finding the perfect draft angle. Finding the perfect draft angle depends on so many factors, so it’s hard for people to know exactly what angles to use.

Conclusion

Now you know all about injection molding draft angles. It’s best to stick between 1° and 3° for the best results. If you want high-quality injection molded parts, consider Rapid Axis. We offer full-scale injection molding production, and we can help with your project. Get a free quote today.